Thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of polyurethane production, can solve problems such as hose scrapping, unfavorable production, leakage, etc., and achieve the goals of prolonging service life, enhancing tensile strength and tear resistance, and improving elasticity and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

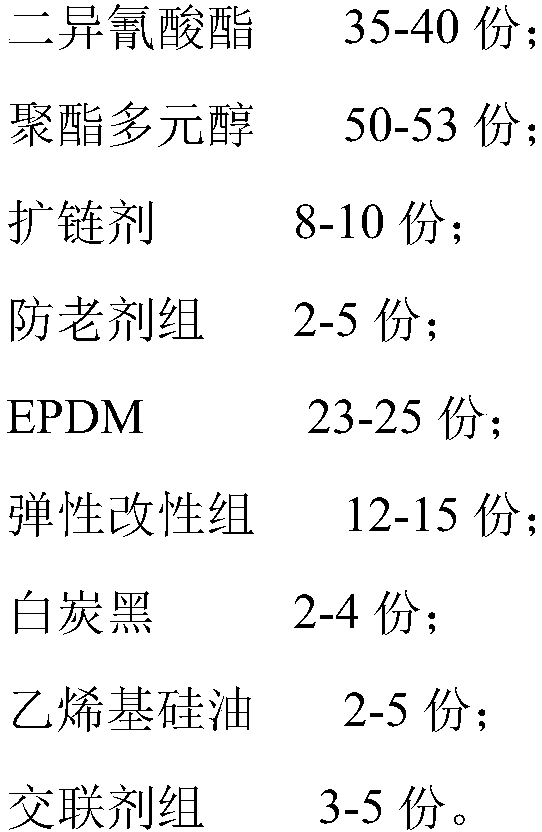

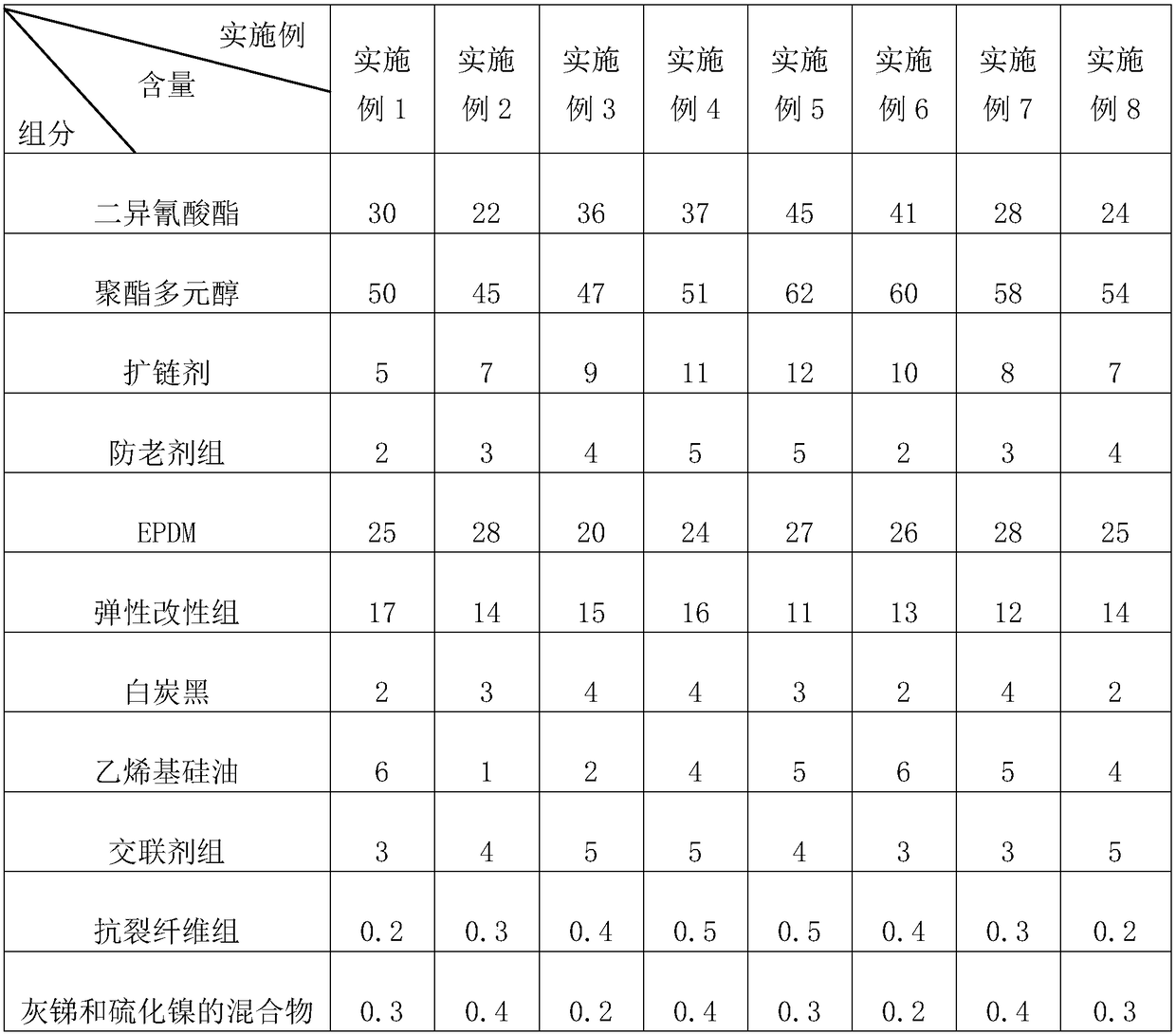

[0036] Embodiment 1-8: a kind of thermoplastic polyurethane elastomer, the component that comprises and its corresponding weight are as shown in table 1, wherein diisocyanate is diphenylmethane diisocyanate; Polyester polyol is diethylene glycol and It is prepared by condensation of adipic acid; the chain extender is a compound of diethylene glycol and 1,4-butanediol; the anti-aging agent group consists of three types: anti-thermal and oxygen aging anti-aging agent, anti-fatigue anti-aging agent and anti-ultraviolet radiation anti-aging agent compound; the elastic modification group is a compound composed of polyolefin plastomer, metallocene polypropylene, and hydrogenated petroleum resin; the crosslinking agent group is composed of hexahydrophthalic anhydride, pyromellitic anhydride , butenedioic anhydride three composition compound; anti-cracking fiber group includes carbon fiber and para-aramid fiber.

[0037] Among them, the number average molecular weight of EPDM is 150,0...

Embodiment 9

[0040] Embodiment 9: A thermoplastic polyurethane elastomer, which differs from Embodiment 1 in that it does not contain crack-resistant fiber groups.

Embodiment 10

[0041] Embodiment 10: A thermoplastic polyurethane elastomer, which differs from Embodiment 1 in that it does not contain the mixture of gray antimony powder and nickel sulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com