Modification method and application of microporous polymer with high nitrogen content

A microporous polymer, high nitrogen content technology, applied in the field of microporous polymer modification, can solve the problem that the specific surface area of the microporous polymer cannot meet the expected requirements, achieve good application value and improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

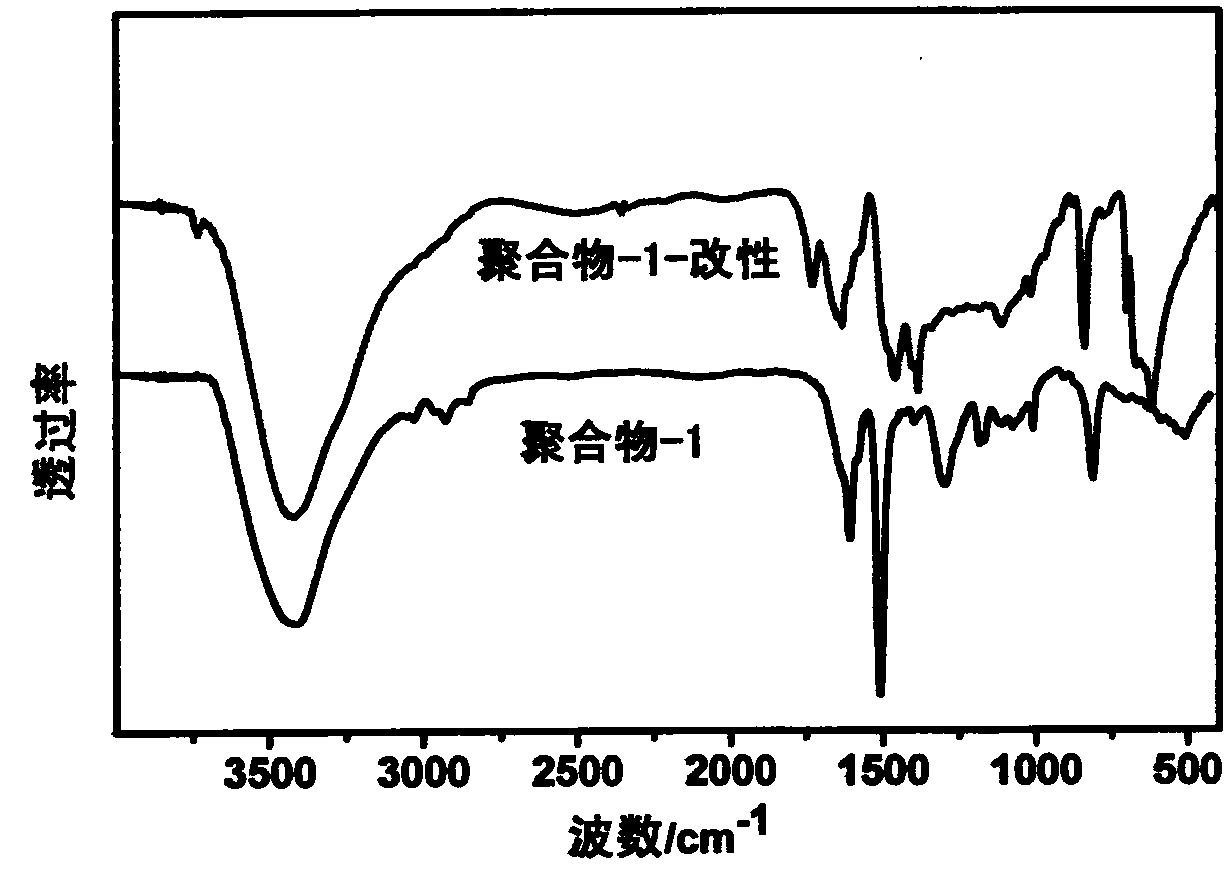

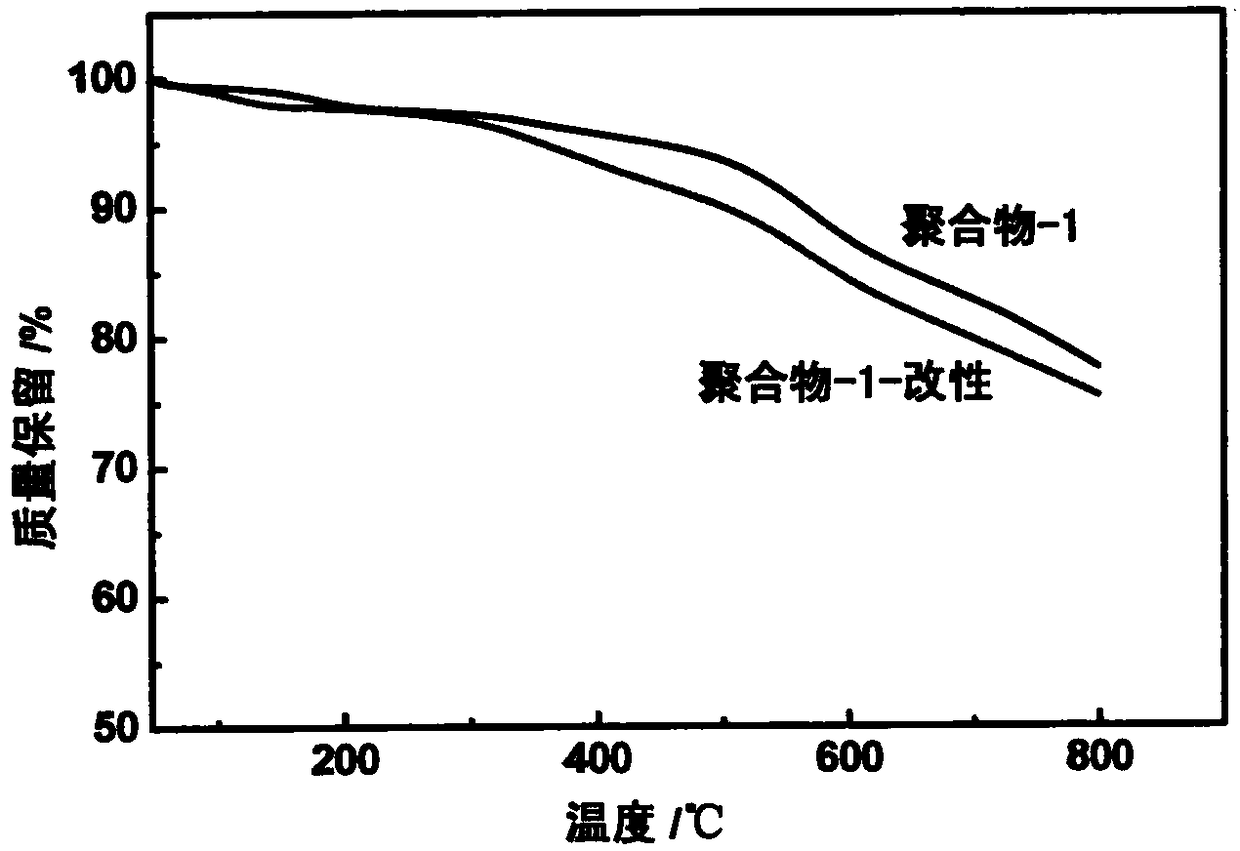

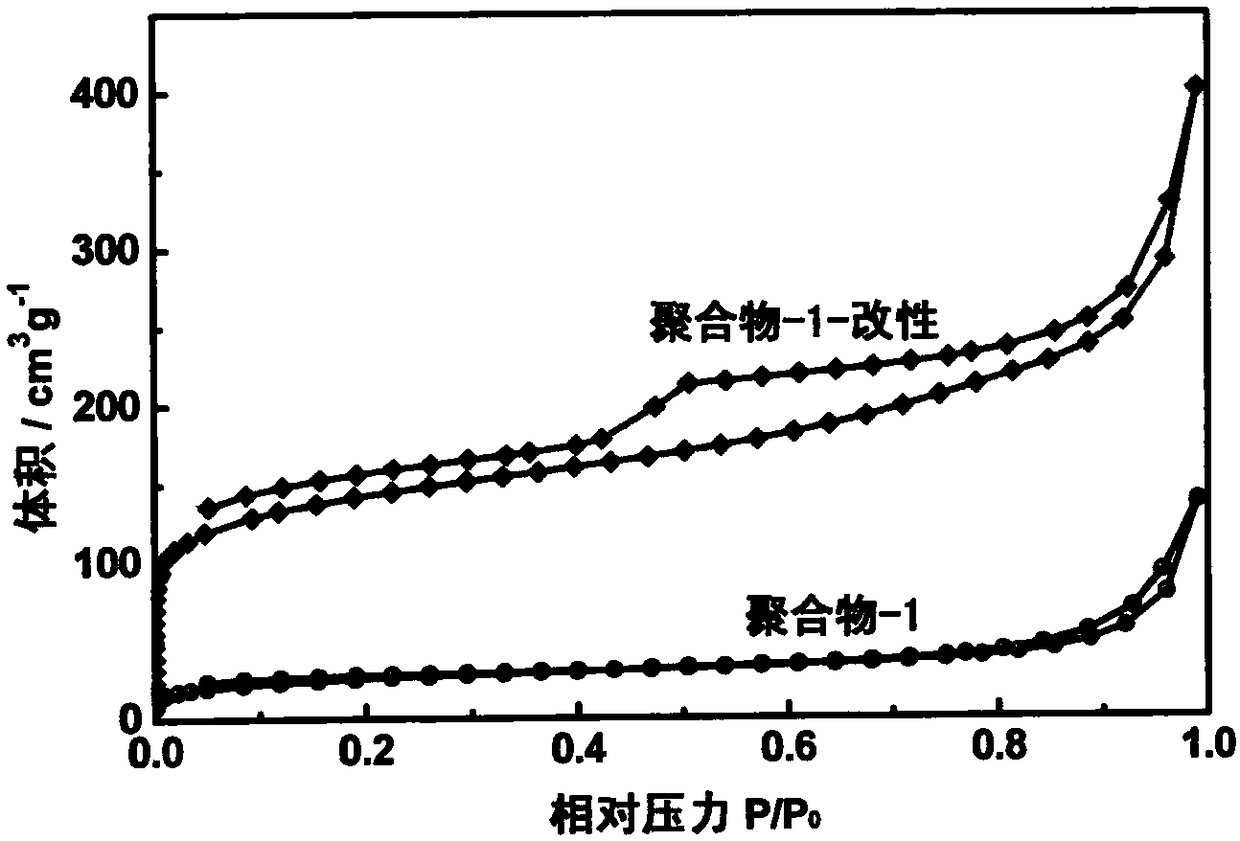

Embodiment 1

[0037] Place tetrakis(4-bromophenyl)methane and p-phenylenediamine in the Schlenk tube in proportion to two monomers, add reaction auxiliary bis(dibenzylideneacetone)palladium, 2-dicyclohexylphosphine-2′ , 4′,6′-triisopropylbiphenyl, sodium tert-butoxide, injected toluene in a nitrogen atmosphere, and reacted in an oil bath at 110°C for 24h. After the reaction, purify with deionized water, chloroform and methanol for 12 hours, and finally place it in a vacuum oven at 60°C for 24 hours to obtain Polymer-1 with a BET specific surface area of 94m 2 / g. Mix and grind Polymer-1 and potassium carbonate into a three-necked flask, inject 30mL N, N-dimethylformamide, microwave for 60 minutes, inject diiodomethane in a nitrogen atmosphere, and react in an oil bath at 152°C 3 days. After the reaction, wash with deionized water for 12 h, and then wash with chloroform for 24 h in a Soxhlet extractor to remove unreacted raw materials. Finally, dry in a vacuum oven at 60°C for 24 hours,...

Embodiment 2

[0043]Place tetrakis(4-bromophenyl)methane and m-phenylenediamine in the Schlenk tube in proportion, and add bis(dibenzylideneacetone)palladium, 2-dicyclohexylphosphine-2' , 4',6'-triisopropylbiphenyl, sodium tert-butoxide, injected toluene in a nitrogen atmosphere, and reacted in an oil bath at 110°C for 24h. After the reaction, purify with deionized water, chloroform and methanol for 12 hours, and finally place it in a vacuum oven at 60°C for 24 hours to obtain Polymer-2 with a BET specific surface area of 47m 2 / g. Mix and grind Polymer-2 and potassium carbonate into a three-necked flask, inject 30mL N,N-dimethylformamide, microwave for 60 minutes, inject diiodomethane in a nitrogen atmosphere, and react in an oil bath at 152°C 3 days. After the reaction, wash with deionized water for 12 h, and then wash with chloroform for 24 h in a Soxhlet extractor to remove unreacted raw materials. Finally, dry in a vacuum oven at 60°C for 24 hours, then wash and dry to obtain a mo...

Embodiment 3

[0049] Place tetrakis(4-bromophenyl)methane and o-phenylenediamine in a Schlenk tube in proportion to two monomers, and add reaction assistant bis(dibenzylideneacetone)palladium, 2-dicyclohexylphosphine-2' , 4',6'-triisopropylbiphenyl, sodium tert-butoxide, injected toluene in a nitrogen atmosphere, and reacted in an oil bath at 110°C for 24h. After the reaction, purify with deionized water, chloroform and methanol for 12 hours, and finally place it in a vacuum oven at 60°C for 24 hours to obtain Polymer-3 with a BET specific surface area of 81m 2 / g. Put polymer-3 and potassium carbonate into a three-necked flask after mixing and grinding, inject 30mL N,N-dimethylformamide, microwave for 60 minutes, inject diiodomethane in a nitrogen atmosphere, and react in an oil bath at 152°C 3 days. After the reaction, wash with deionized water for 12 h, and then wash with chloroform for 24 h in a Soxhlet extractor to remove unreacted raw materials. Finally, dry in a vacuum oven at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com