Method for extracting limonin in lemon seeds by HPMC sedimentation assisted reversed micelles

A technology of limonin and lemon seeds, applied in the directions of steroids, organic chemistry, etc., can solve the problems of waste of limonin resources, adverse environmental effects, low extraction efficiency, etc., and achieve the level of promoting green development, easy promotion, and profit. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

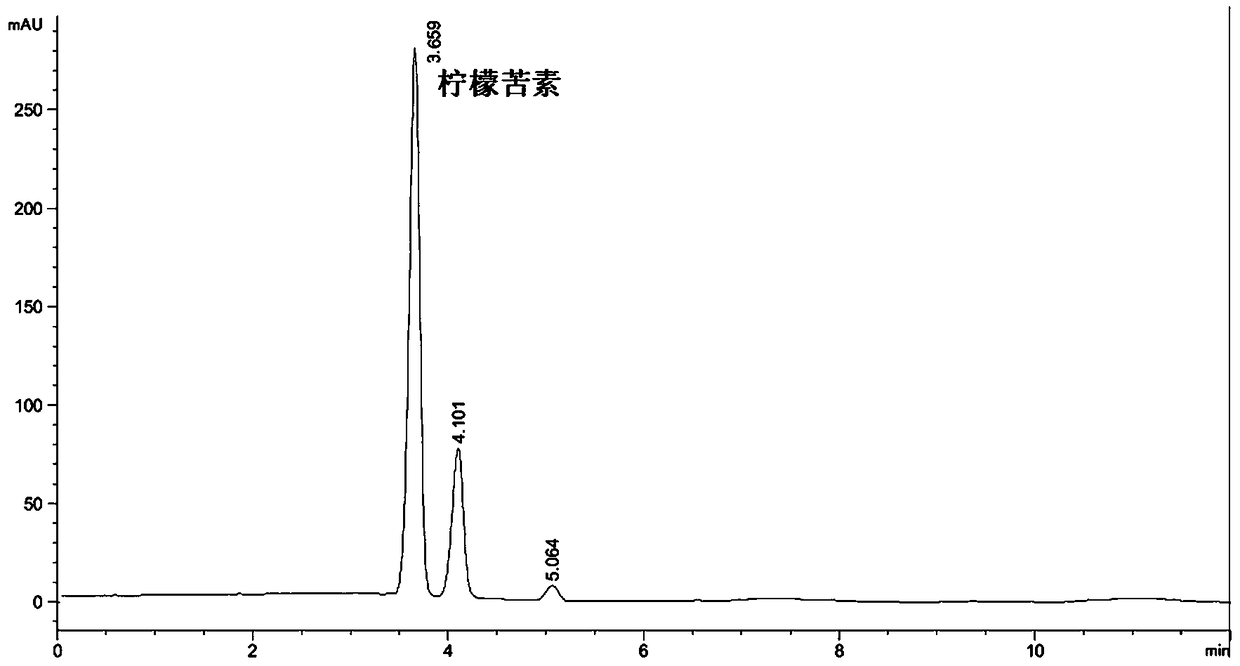

Image

Examples

Embodiment 1

[0042] (1) Drying and crushing of lemon grains or grain fragments: reduce the moisture content of lemon grains or grain fragments to less than 5% at 40°C, crush them with a grinder, and filter through a 150-200 mesh screen for later use.

[0043] (2) Rough extraction: add 0.1mmol / L citric acid-sodium citrate buffer (pH 6.6) to the lemon seed powder in step (1), adjust the ratio of liquid to material to 40:1~50:1, and then place Perform ultrasonic oscillation in an ultrasonic oscillator with an ultrasonic frequency of 40kHz (power 210W), a temperature of 40°C, and a time of 1-1.5h. Finally, it was placed at 4 °C for 10-12 h for later use.

[0044] (3) Initial Limonin Extract: Add HPMC powder with a mass fraction of 0.5% of the total mass to the crude extract prepared in step (2), and use a propeller-type stirrer to stir at a high speed to induce dissolution, and the stirring speed is 2000 r / min, time 0.5~1 h. Then, slowly add solid citric acid to adjust the pH to 5.5-6.0, st...

Embodiment 2

[0053] (1) Drying and crushing of lemon grains or grain fragments: reduce the moisture content of lemon grains or grain fragments to less than 5% at 40°C, crush them with a grinder, and filter through a 150-200 mesh screen for later use.

[0054] (2) Rough extraction: Add 0.1 mmol / L citric acid-sodium citrate buffer solution (pH 6.6) to the lemon seed powder in step (1), adjust the ratio of liquid to material to 40:1~50:1, and then place Ultrasonic oscillation was carried out in an ultrasonic oscillator with an ultrasonic frequency of 30kHz (power 180W), a temperature of 40-45°C, and a time of 2-3 h. Finally, it was placed at 4 °C for 10-12 h for later use.

[0055] (3) Initial Limonin Extract: Add HPMC powder with a mass fraction of 0.5% of the total mass to the crude extract prepared in step (2), and use a propeller-type stirrer to stir at a high speed to induce dissolution, and the stirring speed is 2000 r / min, time 0.5~1 h. Subsequently, slowly add tartaric acid to adju...

Embodiment 3

[0064] (1) Drying and crushing of lemon grains or grain fragments: reduce the moisture content of lemon grains or grain fragments to less than 5% at 40°C, crush them with a grinder, and filter through a 150-200 mesh screen for later use.

[0065] (2) Rough extraction: Add 0.1 mmol / L citric acid-sodium citrate buffer solution (pH 6.6) to the lemon seed powder in step (1), adjust the ratio of liquid to material to 40:1~50:1, and then place Perform ultrasonic oscillation in an ultrasonic oscillator, ultrasonic frequency 60kHz (power 240W), temperature 45~50℃, time 0.5~1.0h. Finally, it was placed at 4 °C for 10-12 h for later use.

[0066](3) Initial Limonin Extract: Add HPMC powder with a mass fraction of 0.5% of the total mass to the crude extract in step (2), and use a propeller-type stirrer to stir at a high speed to induce dissolution, and the stirring speed is 2000 r / min, time 0.5~1 h. Subsequently, slowly add fumaric acid to adjust the pH to 5.5-6.0, stir with a propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com