A kind of high silica glass fiber cotton and preparation method thereof

A technology of high-silica glass fiber and glass fiber cotton, which is applied in the field of inorganic materials, can solve the problem of poor surface finish of glass fiber cotton, achieve the effects of reducing massive dissolution, reducing thermal conductivity, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

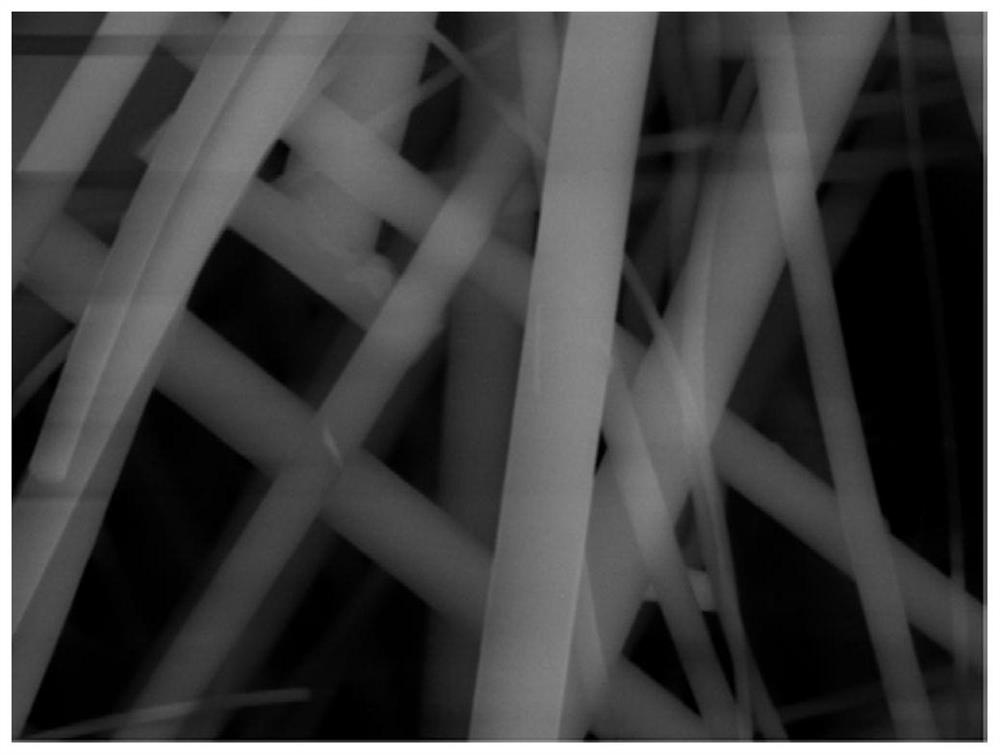

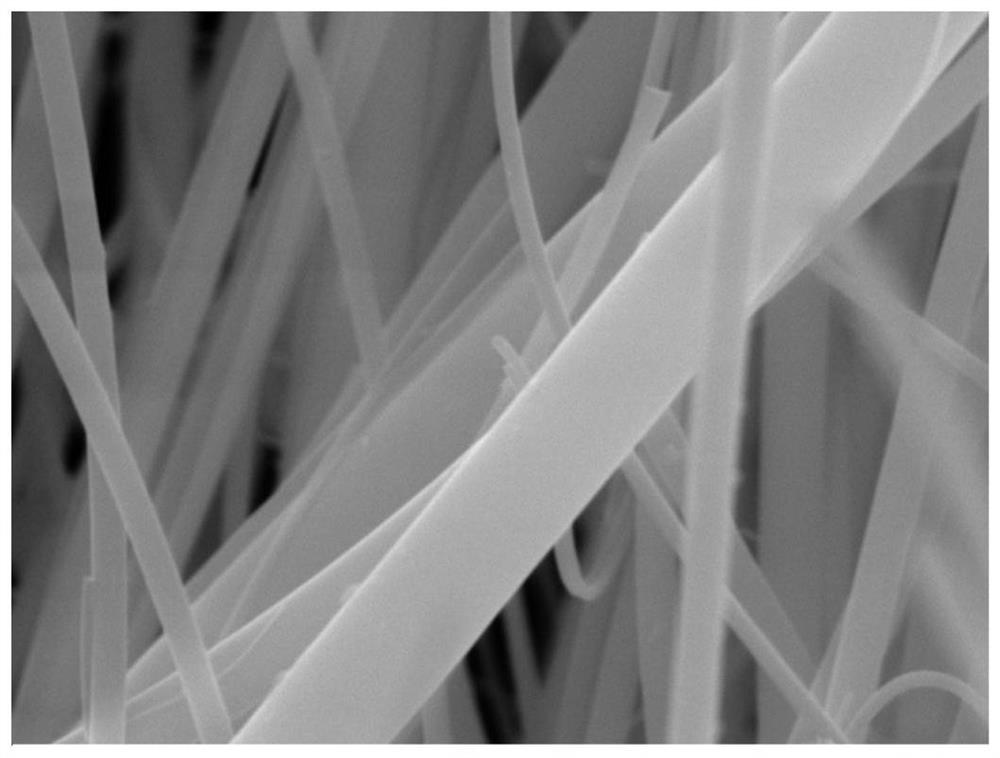

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing high-silica glass fiber wool, which includes the following steps: acid leaching, water washing, drying and thermal sintering. The specific operation is as follows:

[0041] Acid leaching: put 200 grams of basalt wool with a fiber diameter of less than 5 microns in hydrochloric acid with a concentration of 2mol / L, the mass ratio of hydrochloric acid to basalt wool is 80:1, and heat the system at a heating rate of 4°C / min from The normal temperature was raised from 25°C to 50°C at a constant speed, and then raised to 95°C at a constant speed of 3°C / min, and kept for 2 hours. Keep two-way stirring during the period, the stirring speed is 50 rpm, and then squeeze dry;

[0042] Water washing: the semi-finished product after acid leaching is squeezed dry and put into the cleaning bucket, add tap water, the water temperature is 25 ℃, the mass ratio of water and cotton is 50:1, stir evenly with the mixer, wash with water for 30 m...

Embodiment 2

[0046] This embodiment provides a method for preparing high-silica glass fiber wool, which includes the following steps: acid leaching, water washing, drying and thermal sintering. The specific operation is as follows:

[0047] Acid leaching: put 200 grams of basalt wool with a fiber diameter of less than 9 microns in hydrochloric acid with a concentration of 2mol / L, the mass ratio of hydrochloric acid to basalt wool is 80:1, and heat the system at a rate of 3°C / min from The normal temperature was raised from 25°C to 60°C at a constant speed, and then raised to 95°C at a constant speed of 2°C / min, and kept for 5 hours. Keep two-way stirring during the period, the stirring speed is 60 rpm, and then squeeze dry;

[0048] Water washing: the semi-finished product after acid leaching is squeezed dry and put into the cleaning bucket, add tap water, the water temperature is 25 ℃, the mass ratio of water and cotton is 50:1, stir evenly with the mixer, wash with water for 30 minutes, ...

Embodiment 3

[0052] This embodiment provides a method for preparing high-silica glass fiber wool, which includes the following steps: acid leaching, water washing, drying and thermal sintering. The specific operation is as follows:

[0053] Acid leaching: put 200 grams of basalt wool with a fiber diameter of less than 2 microns in hydrochloric acid with a concentration of 0.1mol / L, the mass ratio of hydrochloric acid to basalt wool is 120:1, and heat the system at a rate of 3°C / min. From room temperature 25°C to 60°C at a constant speed, then to 99°C at a rate of 3°C / min, and keep warm for 0.2 hours. Keep two-way stirring during the period, the stirring speed is 20 rpm, and then squeeze dry;

[0054] Water washing: the semi-finished product after acid leaching is squeezed dry and put into the cleaning bucket, add tap water, the water temperature is 25 ℃, the mass ratio of water and cotton is 50:1, stir evenly with the mixer, wash with water for 30 minutes, after draining, Squeeze out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com