Airflow spherification reactor and method for preparing polymer-based spherical powder material by same

A powder material and reactor technology, applied in the field of 3D printing, can solve the problems of poor powder mixing effect and powder shape, large consumption of organic solvent, low production efficiency, etc., and achieve the goal of adjusting product performance, excellent mechanical properties, and preventing accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

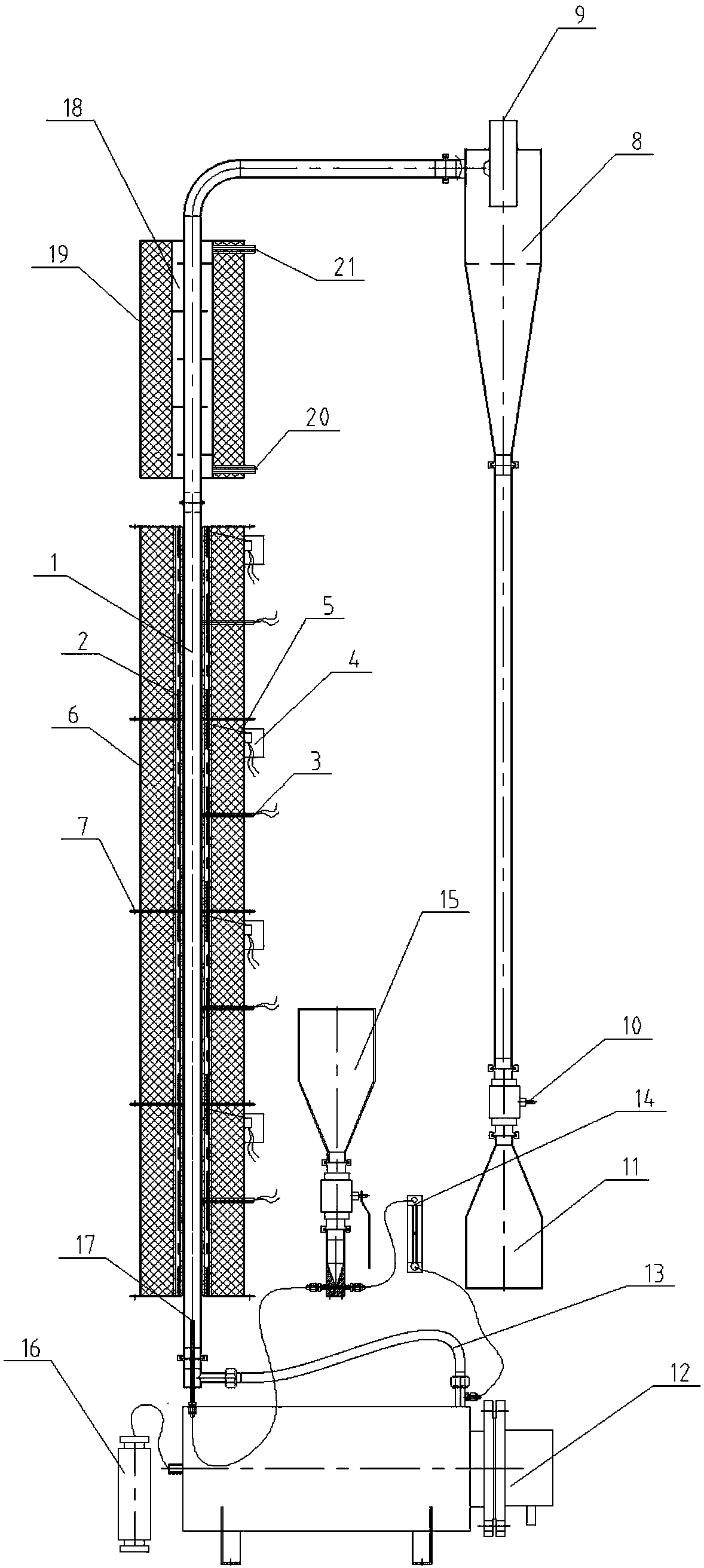

[0041] Reference attached figure 1 and 2 . An airflow spheroidization reactor comprises a powder material conveying system, a reactor body, a condensing system and a cyclone separator assembly connected in sequence.

[0042] The powder material conveying system includes an air heater 12 , a feeder 15 and a feed nozzle 17 , one end of the feeder 15 is connected to the air heater 12 , and the other end is connected to the reactor body through the feed nozzle 17 .

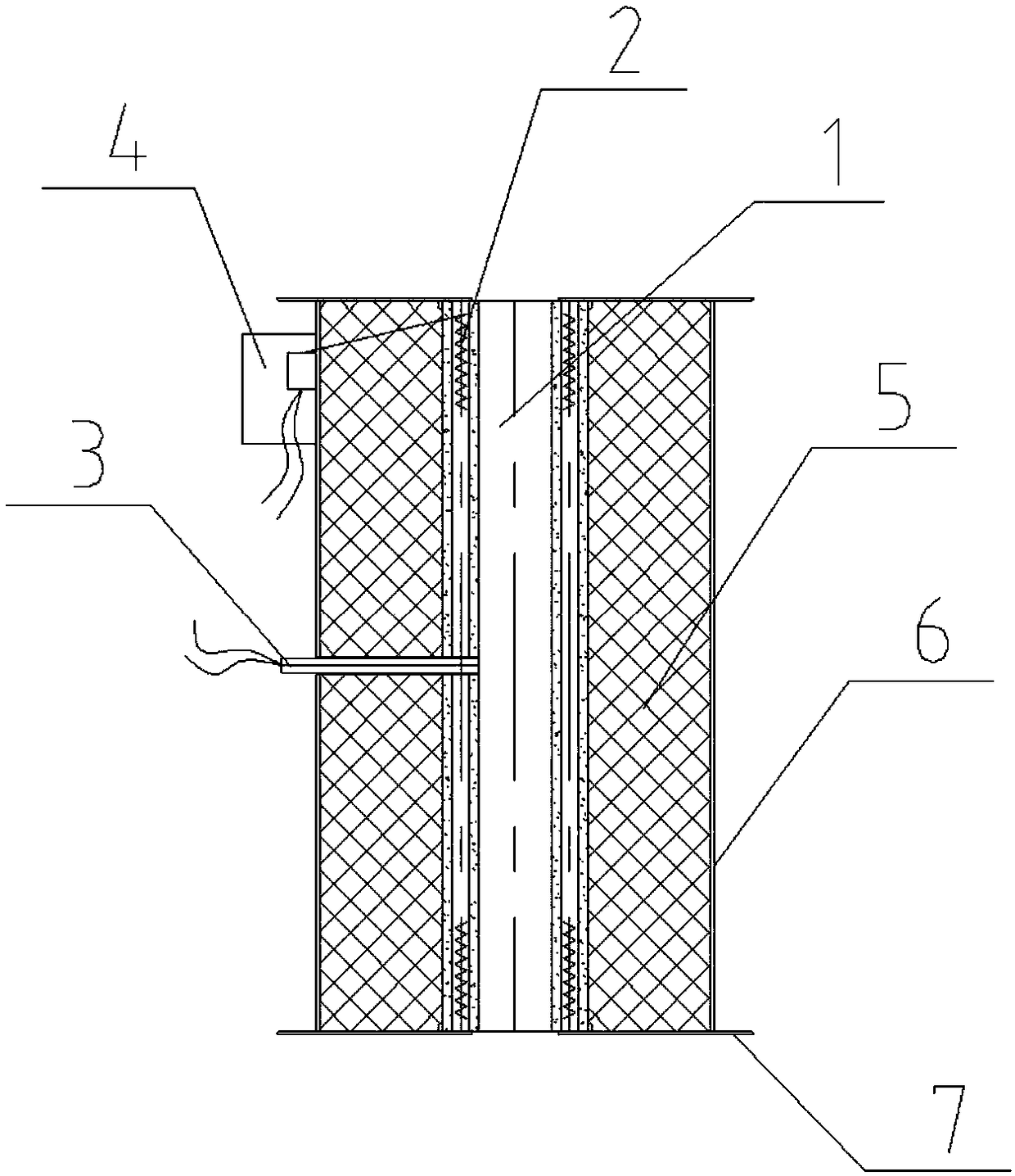

[0043] The reactor body includes a tubular gasifier 1, an electric heating wire 2, a thermocouple 3, a junction box 4, an insulation layer 5, and an insulation shell 6. The electric heating wire 2 is wound on the outer layer of the tubular gasification furnace 1, and the The tubular gasifier 1 is heated to compensate the heat in the reactor. The thermocouple 3 runs straight through the inner wall of the tubular gasifier 1 along the radial direction to monitor the internal temperature of the reactor. The insulation...

Embodiment 2

[0050] The airflow spheroidization reactor of Example 1 is used to prepare polymer-based spherical powder materials, air is provided by an air compressor, and solid powder materials are provided by feeder 15, and the air flow flows through the lower part of feeder 15 to take away solid powder materials to form The gas-solid mixture enters the reactor body through the feeding nozzle 17. It is further heated in the reactor body. Through gas-solid heat transfer, the temperature of the reactor cavity is heated above the melting point of the powder material, so that the solid powder material is completely melted. For solidification and forming, the cyclone separator 8 is used for gas-solid separation, and the silo 11 collects spherical powder materials.

Embodiment 3

[0052] The difference from the airflow spheroidization reactor in Example 1 is that the powder material conveying system also includes a corrugated hose 13 connecting the air heater 12 and the inlet of the tubular gasifier 1 . At the entrance of the reactor body, the central feeding nozzle provides materials for the reactor body, and the corrugated hose 13 provides preheated air to form a protective airflow for the central material. After the two airflows enter the reactor, they are mixed and dispersed to prevent the material from sticking to the wall and agglomerating , which is conducive to maintaining the shape of the product.

[0053] When in use, the air flow spheroidization reactor is provided with compressed air by an air compressor, the compressed air is preheated by the air heater 12, and then divided into two streams, one stream flows through the feeder 15 The lower part takes away the solid powder material to form a gas-solid mixture, which enters the reactor body f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com