Toluene disproportionation and transalkylation catalyst and preparation method thereof

A technology of transalkylation and toluene disproportionation, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as reducing the loss rate of aromatic rings, and achieve the reduction of benzene ring loss, alleviation of aromatic ring loss, Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concentration of 3.9mL is 3.77g Pt / L of H 2 PtCl 6 The aqueous solution was poured into 300g ethylene glycol (EG) and stirred for 18h. Adjust the pH to 13.0 with NaOH EG solution (1 mol / L), blow in nitrogen gas, raise the temperature to 95°C, and keep it for 2h. After cooling down to room temperature, 10 g of hydrogen mordenite (SiO 2 / Al 2 o 3 The molar ratio was 25), stirred vigorously, and adjusted the pH of the solution to 1.0 with aqueous HCl (1mol / L) for 3h. After filtering, washing with water, drying at 120°C for 12h, and roasting in air (500°C, 3h), the solid product S1 was obtained.

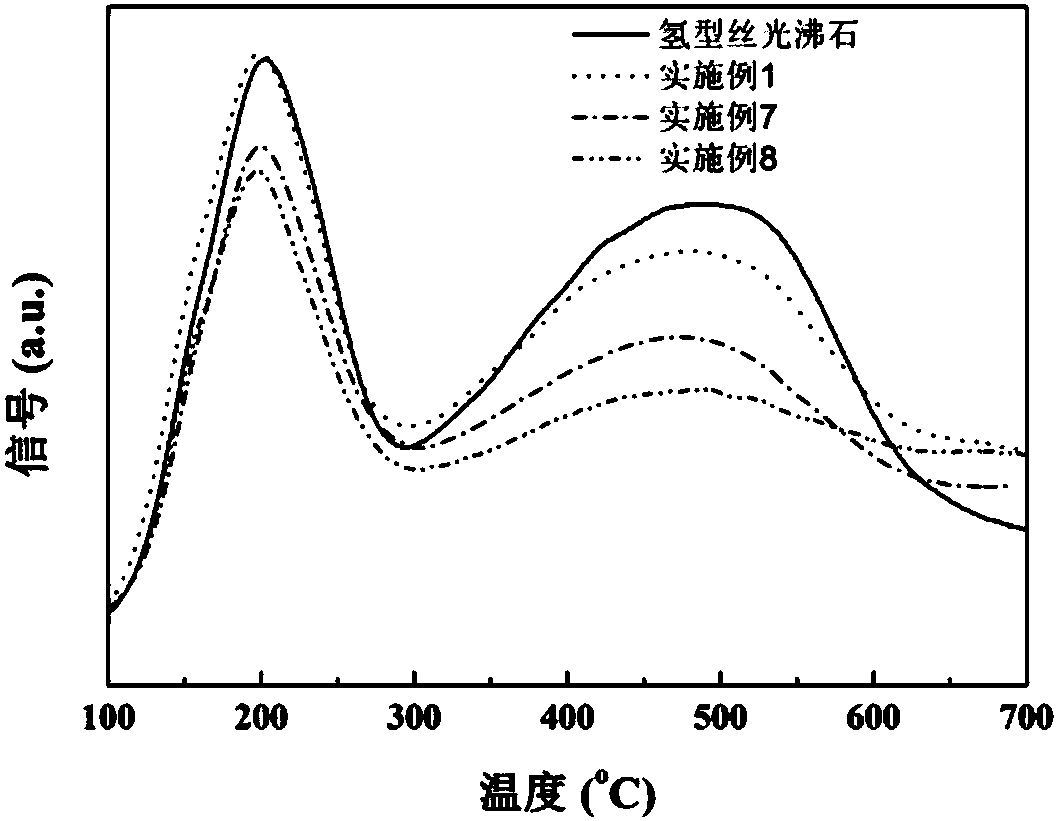

[0045] The platinum content was determined to be 0.1 wt% by ICP analysis. figure 1 It is the transmission electron microscope figure after (500 ℃, 3h) reduction of gained product S1 of embodiment 1, it can be seen that the particle diameter of platinum metal nanoparticles is 2-5nm, the particle size distribution is narrow, and the particle diameter is larger than the p...

Embodiment 2

[0047] The concentration of 3.9mL is 3.77g Pt / L of H 2 PtCl 6 The aqueous solution was poured into a mixed solution of 220g ethylene glycol (EG) and 80g water, and stirred for 18h. Adjust the pH to 13.0 with EG solution of NaOH (1mol / L), raise the temperature to 95°C and keep it for 2h. After cooling down to room temperature, 10 g of hydrogen mordenite (SiO 2 / Al 2 o 3 The molar ratio was 25), stirred vigorously, and adjusted the pH of the solution to 1.0 with aqueous HCl (1mol / L) for 3h. Suction filtration, washing with water, drying at 120°C for 12h, and calcination at 500°C in air for 3h gave the solid product S2. The platinum content was determined to be 0.1 wt% by ICP analysis. The diameter of the platinum metal nanoparticles is 3-5nm.

Embodiment 3

[0049] The concentration of 3.9mL is 3.77g Pt / L of H 2 PtCl 6 The aqueous solution was poured into 300g ethylene glycol (EG) and stirred for 18h. Adjust the pH to 10.0 with NaOH EG solution (1 mol / L), blow in nitrogen gas, raise the temperature to 95°C, and keep it for 2h. After cooling down to room temperature, 10 g of hydrogen mordenite (SiO 2 / Al 2 o 3 The molar ratio was 25), stirred vigorously, and adjusted the pH of the solution to 1.0 with aqueous HCl (1mol / L) for 3h. After filtering, washing with water, drying at 120°C for 12h, and roasting in air (500°C, 3h), the solid product S3 was obtained.

[0050] The platinum content was determined to be 0.1 wt% by ICP analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com