A temperature control method for liquid metal batteries in energy storage applications

A liquid metal battery, energy storage technology, applied in battery temperature control, secondary battery, secondary battery repair/maintenance, etc. The problem of capacity fading and additional power loss, the effect of improving energy efficiency and reducing self-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

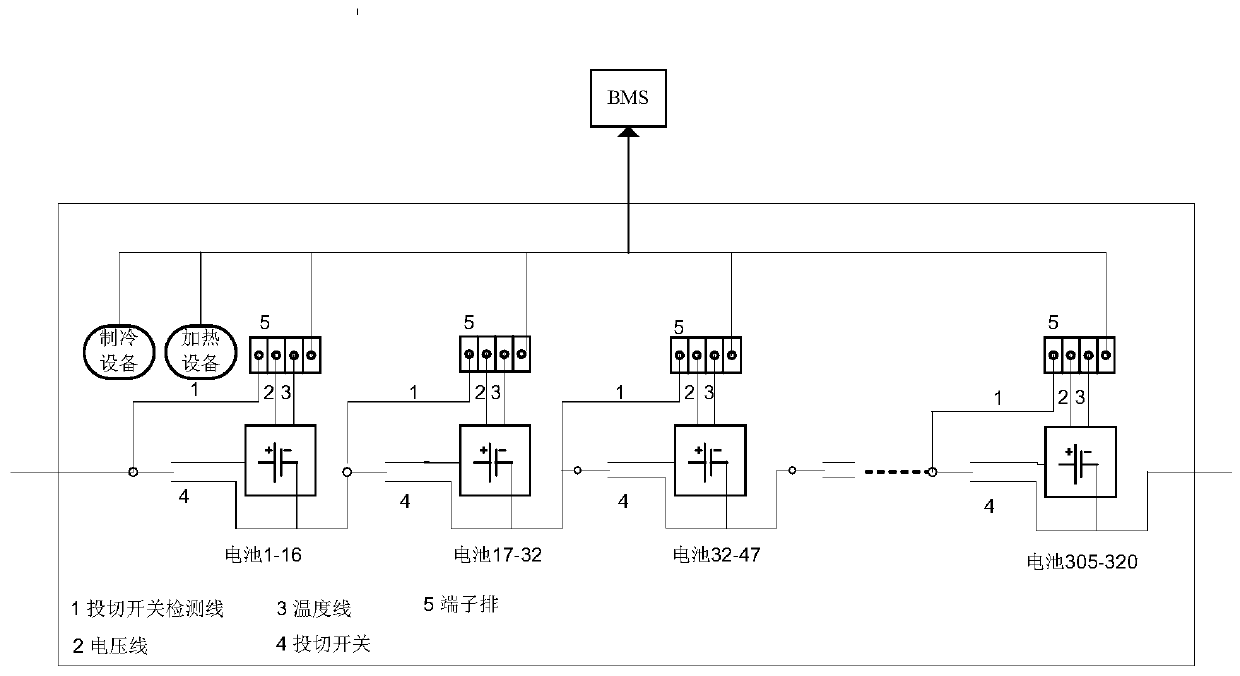

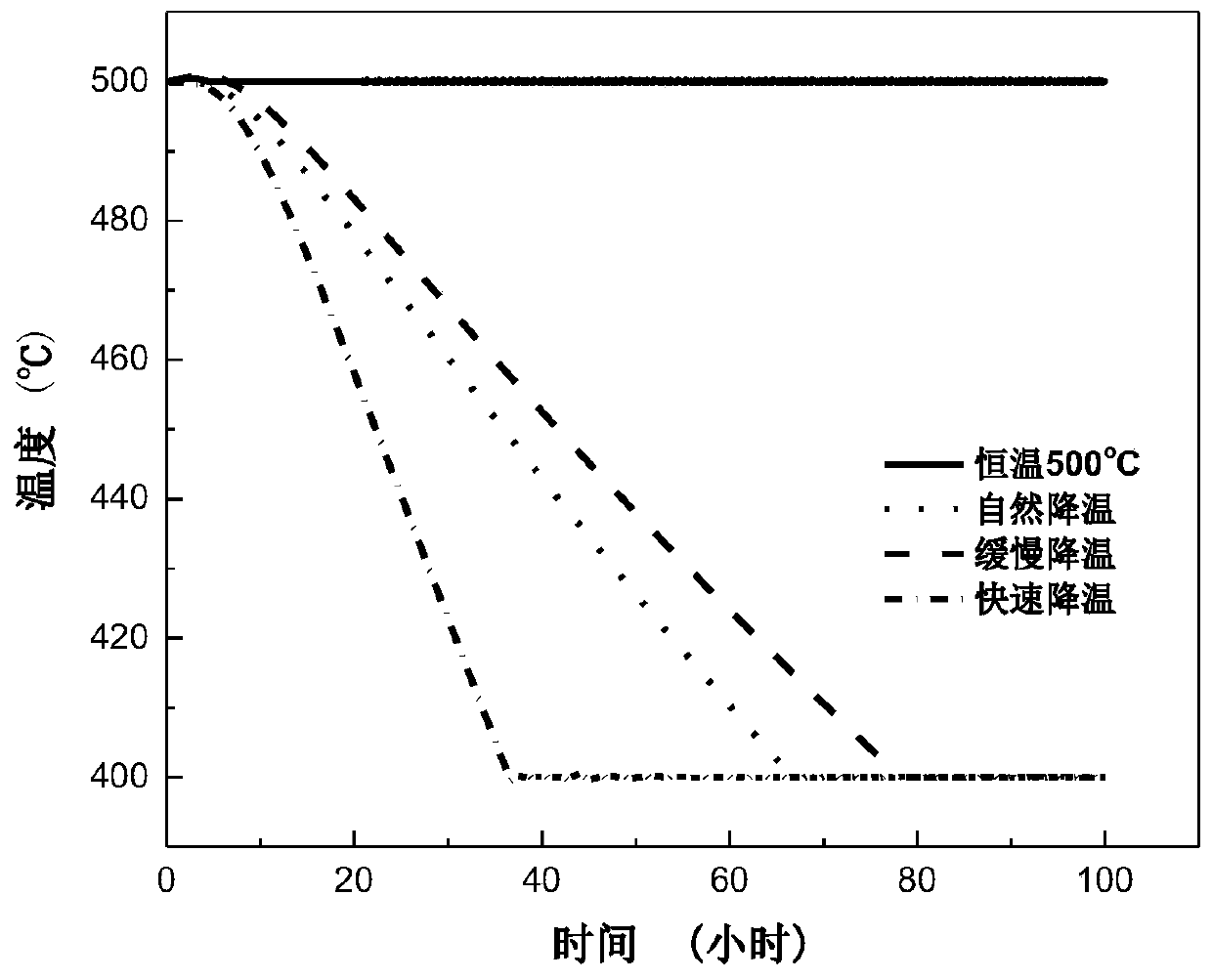

[0036] When the battery is in the suspend mode, the temperature of the battery is cooled to 400°C by means of natural temperature control. The specific operation steps are as follows:

[0037] ① Send instructions to the temperature controller through the battery management system (BMS) to turn on the no-power operation state, so that the batteries in the battery pack unit can reduce the temperature of the batteries through natural convection and heat dissipation of the external air.

[0038] ② When the average temperature in the battery pack drops to 400°C, a temperature signal is sent to the battery management system through the temperature detector.

[0039] ③The battery management system sends an instruction to the temperature controller to turn on the heating mode. In this implementation case, the heating and heat preservation power is selected as 1000W, so that the average temperature of the battery pack is maintained at 400°C.

[0040] figure 2 It is a schematic diagra...

specific Embodiment 2

[0042] When the battery is in the suspend mode, the temperature of the battery is lowered to 400°C by slowly cooling the temperature control method. The specific operation steps are as follows:

[0043] ①Send instructions to the temperature controller through the battery management system (BMS), turn on the low power to maintain the running state (the power is less than the heat dissipation power of the battery pack, and the specific power is determined by the cooling rate required under different working conditions, in this case In the embodiment, the compensation power is selected as 40W), so that the battery in the battery pack unit slowly reduces the temperature of the battery through natural convection heat dissipation to the outside air and low-power thermal energy compensation.

[0044] ② When the average temperature in the battery pack drops to 400°C, a temperature signal is sent to the battery management system through the temperature detector.

[0045] ③The battery m...

specific Embodiment 3

[0048] When the battery is in the suspend mode, the temperature of the battery is cooled to 400°C by means of rapid cooling temperature control. The specific operation steps are as follows:

[0049] ①Send instructions to the temperature controller through the battery management system (BMS) to start the non-power running state.

[0050] ②The battery management system (BMS) sends instructions to the refrigeration equipment to start the cooling operation state (its power is greater than the heat dissipation power of the battery pack, and its specific power is determined by the cooling rate required under different working conditions. In this embodiment, the The power of the cooling device is 400W) so that the battery in the battery pack unit can cool down the temperature of the battery through forced convection.

[0051] ③When the average temperature in the battery pack drops to 400°C, a temperature signal is sent to the battery management system through the temperature detector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com