High-frequency high-performance acoustic surface wave device and preparation method thereof

A surface acoustic wave device and substrate technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, device material selection, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of deteriorating device performance, Poor device uniformity, large propagation loss and other problems, to achieve the effect of huge application prospects, good consistency, and small propagation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

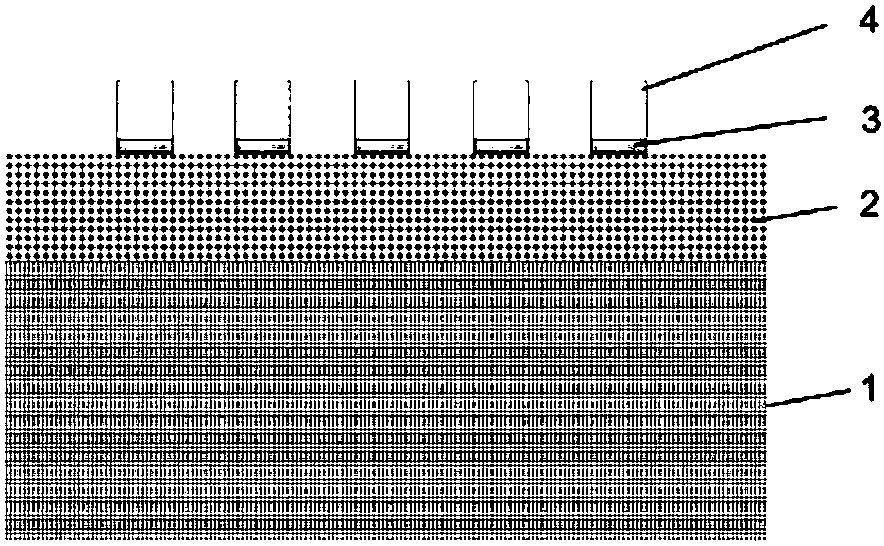

[0046] Example 1, YZ LiNbO 3 Fabrication of Surface Acoustic Wave Devices on Single Crystal Thin Film / 6H-SiC Single Crystal Substrate Structure

[0047] (1) 6H-SiC single crystal substrate (thickness 300μm), YZ LiNbO 3 The substrate was ultrasonically cleaned with acetone, alcohol, and deionized water for 5 minutes each, then rinsed with deionized water for 2 minutes, and finally dried with nitrogen gas.

[0048] (2) By direct bonding, the YZ LiNbO 3 The process surface of the substrate is contact-bonded with the smooth surface of the 6H-SiC single crystal substrate. The conditions of the direct bonding method are as follows: in a vacuum of 8.0×10 -5 Pa, the pressure is 800N, and annealing is carried out at 200°C for 5 hours to enhance the bonding force.

[0049] (3) Using the wafer grinding process, the YZ LiNbO 3thinned to 30 μm, and then chemically mechanically polished to 0.8 μm to obtain YZ LiNbO on 6H-SiC single crystal substrate 3 single crystal film.

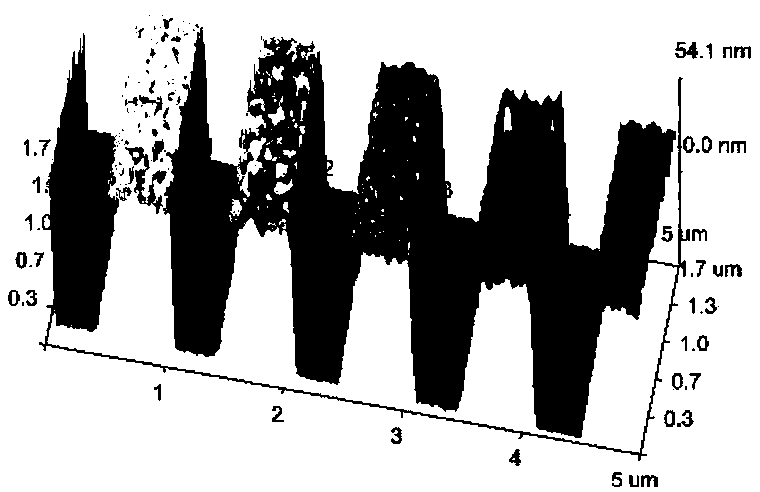

[0050] (4...

Embodiment 2、42

[0058] Example 2, 42°Y-X LiTaO 3 Fabrication of Surface Acoustic Wave Devices on Single Crystal Thin Film / 6H-SiC Single Crystal Substrate Structure

[0059] (1) 6H-SiC single crystal substrate (thickness 500μm), 42°Y-X LiTaO 3 The substrate was ultrasonically cleaned with acetone, alcohol, and deionized water for 5 minutes each, then rinsed with deionized water for 2 minutes, and finally dried with nitrogen gas.

[0060] (2) Using the direct bonding method, the 42°Y-X LiTaO 3 The process surface of the substrate is contact-bonded with the smooth surface of the 6H-SiC single crystal substrate. The conditions of the direct bonding method are as follows: in a vacuum of 9.0×10 -5 Pa, the pressure is 800N, and annealing is carried out at 250°C for 8 hours to enhance the bonding force.

[0061] (3) Using the wafer grinding process, the 42°Y-X LiTaO 3 thinned to 50 μm, and then chemically mechanically polished to 0.2 μm to obtain 42°Y-X LiTaO on 6H-SiC single crystal substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com