Preparation method of antibacterial tipping paper for water-based ink printing

A water-based ink and antibacterial water technology, applied in ink, papermaking, wrapping paper, etc., can solve problems such as odor, breeding bacteria, and affecting smoke absorption, and achieve odor improvement, enhanced hydrogen bond force, and reduced distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

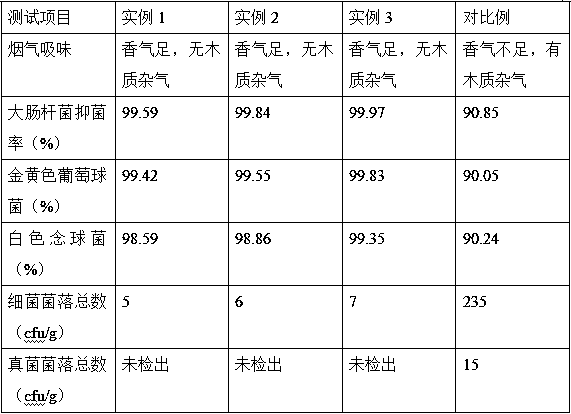

Examples

Embodiment Construction

[0026]Put the tobacco leaves into a pulverizer for 3-4 hours to obtain tobacco leaf powder, put 200-220g of tobacco leaf powder and 250-300mL of water into a beater for beating for 2-3 hours to obtain tobacco leaf pulp, add 40 ~50mL of sodium hydroxide solution with a mass fraction of 40%, heating to 100~110℃, heat preservation and cooking for 4~5h, filtering and separating to remove the filtrate to obtain delignified wood pulp; place the above delignified wood pulp in In the stirred tank, add 30-40mL aluminum chloride solution with a mass fraction of 5% into the stirred tank, start the agitator, stir and mix at a speed of 200-250r / min for 30-40min, and then pour it into the wood pulp at room temperature A mixture of propylene and acetyl chloride with a volume ratio of 3:1 was introduced at a ventilation rate of 30-40mL / min. After ventilation for 30-35 minutes, the stirred tank was sealed and stirred for 3-4 hours to obtain scented wood pulp; the concentration was 4.0 mol / L Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com