Thermosetting shape memory resin based on bismaleimide and preparation method thereof

A bismaleimide and thermosetting technology, which is applied in the field of thermosetting shape memory resin and its preparation, can solve problems such as deterioration and lower tensile strength, and achieve moderate crosslink density, avoid brittle fracture, and high shape fixation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

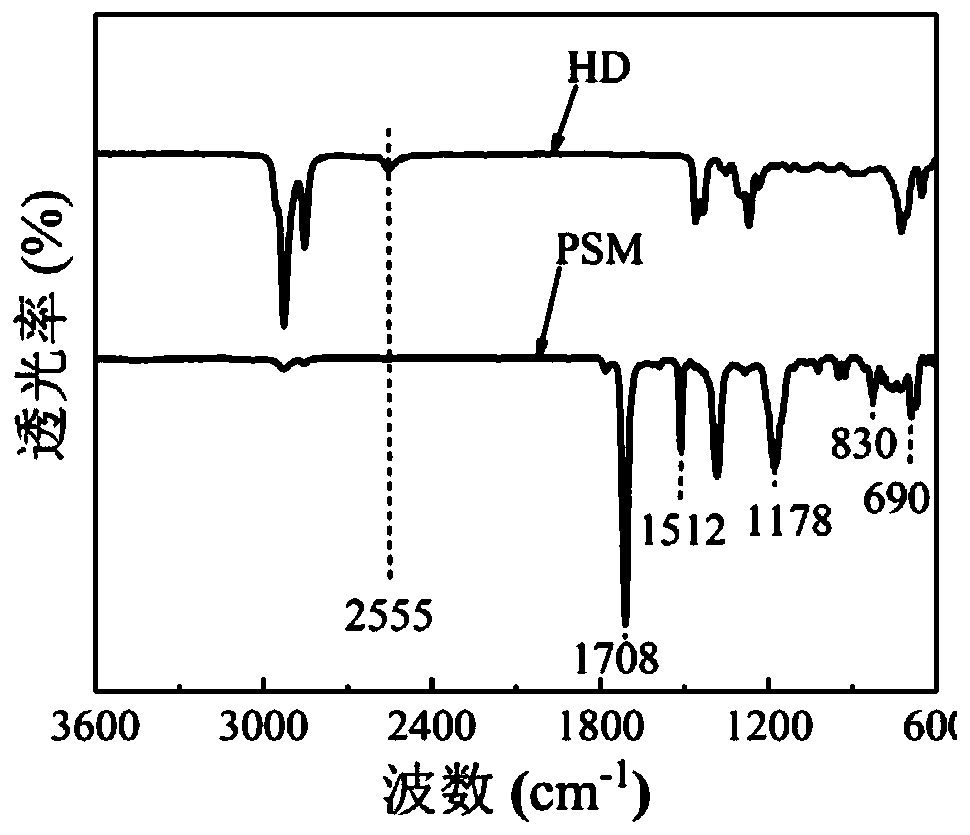

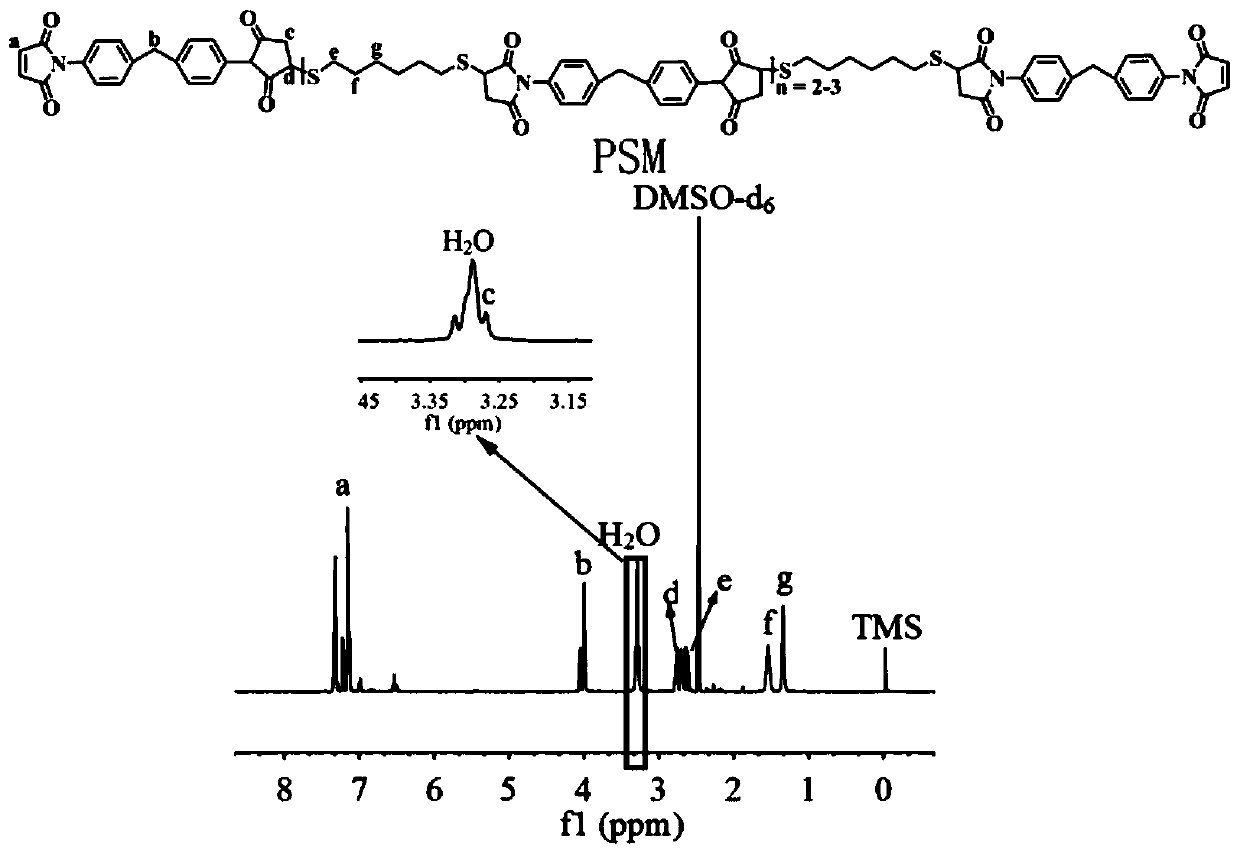

[0041] Add 89.6 g of N,N-(4,4-methylenediphenyl)bismaleimide and 22.5 g of 1,6-hexanedithiol to 500 mL of m-cresol to form 0.8 mol L -1 solution; add 2 mL of triethylamine dropwise to the solution, N 2 Under protection and stirring conditions, react at room temperature for 4h. After the reaction, the reaction solution was added into methanol acidified with glacial acetic acid, precipitated, filtered, washed with methanol, and dried to obtain a linear oligomer, which was designated as PSM. The number average molecular weight of PSM is 2434 g mol -1 , the dispersion index (PDI=Mw / Mn) is 1.48. Infrared (IR) spectrum and H NMR spectrum of PSM ( 1 H NMR) see attached figure 1 and 2 .

[0042] 10.0g of O,O´-diallyl bisphenol A, 55.2g of PSM (this PSM is used in the following examples, no special note) and 3.5g of N,N-(4,4-methylenebisphenol Phenyl)bismaleimide was mixed and vigorously stirred at 130°C for 30min to obtain a clear and transparent prepolymer. Pour the prepolym...

Embodiment 2

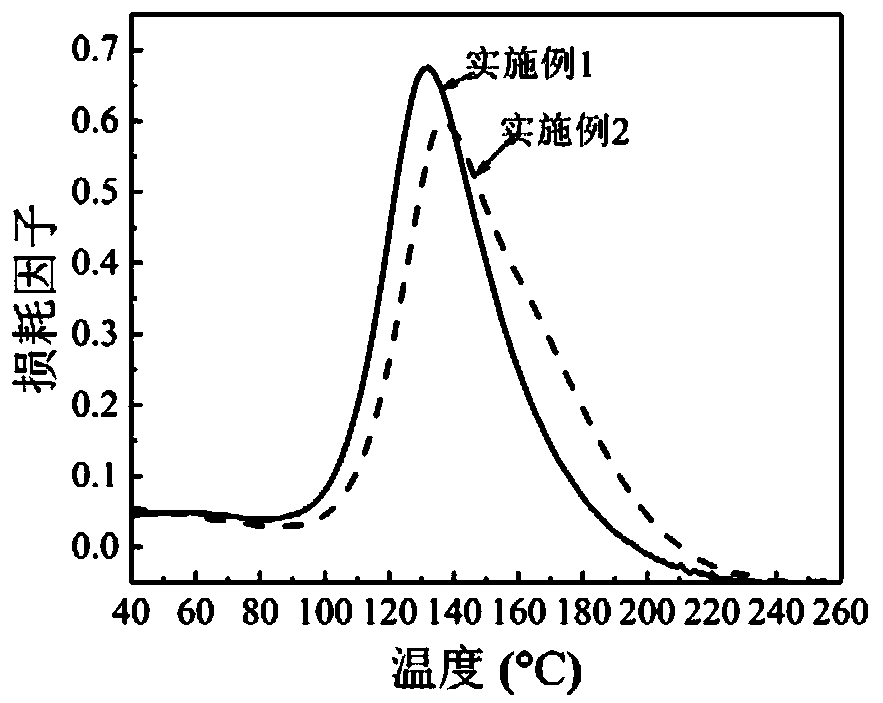

[0046] Mix 10.0g O,O´-diallyl bisphenol A, 47.3g PSM and 4.6g N,N-(4,4-methylenediphenyl)bismaleimide at 130℃ Stir vigorously for 30 minutes to obtain a clear and transparent prepolymer. Pour the prepolymer into the preheated mold, and put the mold into a vacuum oven at 130°C for degassing. Then, the mold is put into a blast drying oven. Curing and post-treatment were performed sequentially according to the procedures of 140°C / 2h+160°C / 2h+180°C / 2h and 200°C / 6h. After the end, it was naturally cooled in an oven to obtain a bismaleimide-based thermosetting shape memory resin, denoted as 6BHD. Its glass transition temperature, crosslinking density, initial decomposition temperature, impact strength, tensile strength, fracture strain and shape memory properties are respectively shown in the attached image 3 , 4 , 5, 6, 7, 8 and Schedule 1.

[0047] See attached image 3 , which is the loss factor (Tan δ )-Temperature curve. As can be seen therefrom, the glass transition ...

Embodiment 3

[0060] Mix 10.0g O,O´-diallyl bisphenol A, 39.5g PSM and 5.8g N,N-(4,4-methylenediphenyl)bismaleimide at 130°C Stir vigorously for 30 minutes to obtain a clear and transparent prepolymer. Pour the prepolymer into the preheated mold, and put the mold into a vacuum oven at 130°C for degassing. Then, the mold is put into a blast drying oven. Curing and post-treatment were performed sequentially according to the procedures of 130°C / 2h+150°C / 1h+165°C / 4h+180°C / 2h and 200°C / 6h. After the end, cool naturally with the oven to obtain a thermosetting shape memory resin based on bismaleimide; glass transition temperature T g The temperature is 145°C, the initial decomposition temperature is not lower than 370°C, the tensile strength at room temperature is greater than 51MPa, the elongation at break is greater than 35%, and the shape recovery rate and shape fixation rate are both greater than 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com