Filtering bag cage framework with denitration function and preparation method thereof

A functional and cage technology, applied in the field of environmental protection catalytic materials and material processing, can solve the problems of high construction cost, easy powdering and falling off of catalysts, and high operating costs, and achieve the effects of prolonging service life and reducing poisoning and wear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of denitrification catalyst powder

[0031] ①According to the mass ratio of catalyst active component composite oxide to catalytic promoter composite oxide is 1:0.01, the element molar ratio of Mn / Nb / Ce is 1:0.2:0.2; Fe / Ni / La / Co / Cu element The molar ratio is 1:0.5:0.25:0.25:0.3, and the active component precursors manganese nitrate, cerium nitrate, niobium oxalate and catalytic aid precursors iron nitrate, nickel acetate, cobalt nitrate, copper nitrate and lanthanum nitrate are calculated respectively. Adding amount, dissolve it in deionized water, stir it with a magnetic stirrer for 2min to make it completely dissolved;

[0032] ②Dry the prepared solution at 60°C for 2h, then put it into a muffle furnace for calcination, the calcination temperature is 350°C, the calcination time is 10h, and the denitrification catalyst can be obtained after natural cooling. The catalyst was then ground into a powder with an average particle size of 1 μm.

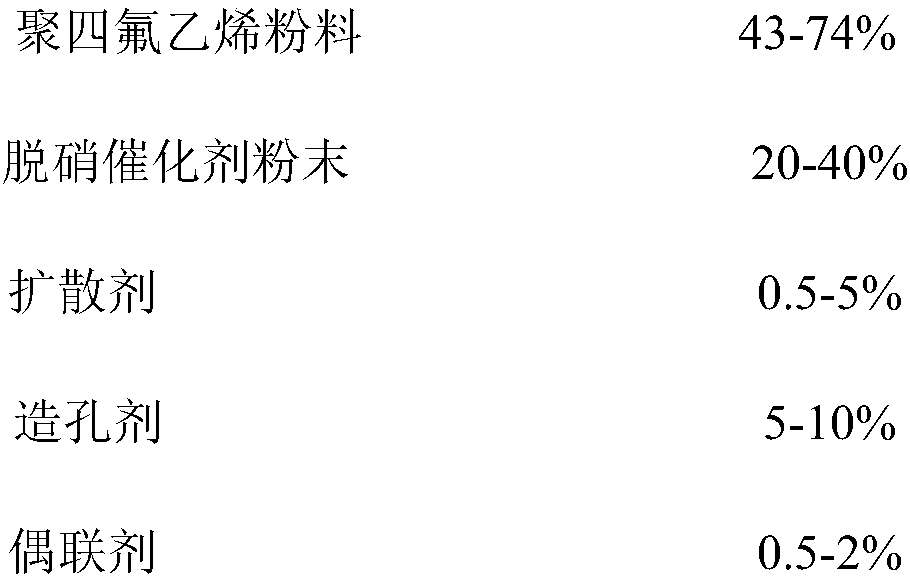

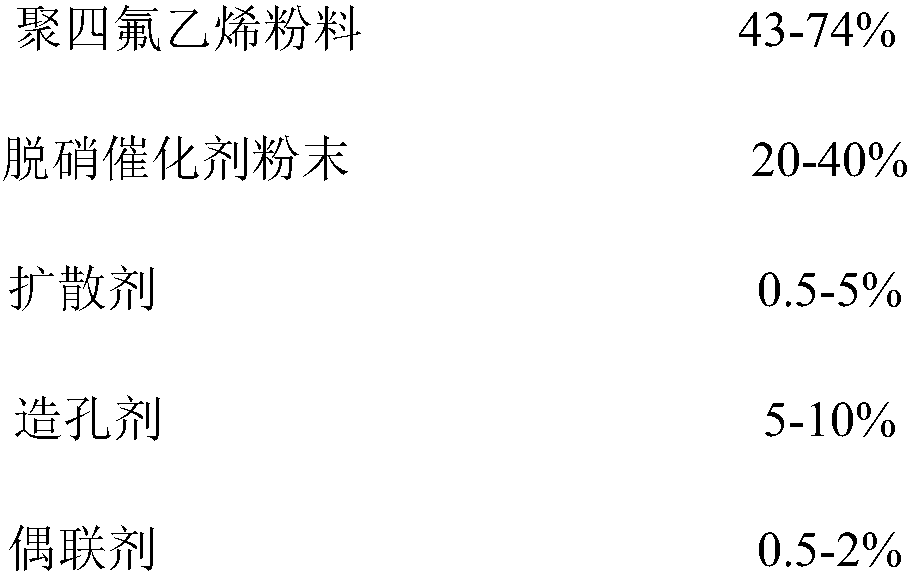

[0033] 2. Pr...

Embodiment 2

[0046] 1. Preparation of denitrification catalyst powder

[0047] ①According to the mass ratio of catalyst active component composite oxide to catalytic promoter composite oxide is 1:0.15, the element molar ratio of Mn / Nb / Ce is 1:0.2:0.4; Fe / Ni / La / Co / Cu element The molar ratio is 1:0.5:0.25:0.25:0.25, and the active component precursors manganese nitrate, cerium nitrate, niobium oxalate and catalytic promoter precursors iron nitrate, nickel acetate, cobalt nitrate, copper nitrate and lanthanum nitrate are calculated respectively. Adding amount, dissolve it in deionized water, stir it with a magnetic stirrer for 6 minutes, and make it dissolve completely;

[0048] ②Dry the prepared solution at 75°C for 6h, then put it into a muffle furnace for calcination, the calcination temperature is 550°C, the calcination time is 4h, and the denitrification catalyst can be obtained after natural cooling. The catalyst was then ground into a powder with an average particle size of 0.3um.

...

Embodiment 3

[0059] 1. Preparation of denitrification catalyst powder

[0060] ①According to the mass ratio of catalyst active component composite oxide to catalytic promoter composite oxide is 1:0.01, the element molar ratio of Mn / Nb / Ce is 1:1:1; Fe / Ni / La / Co / Cu element The molar ratio is 1:1:0:0:0.5, respectively calculate the addition amount of the active component precursors manganese nitrate, cerium nitrate, niobium oxalate and catalytic promoter precursors iron nitrate, nickel acetate and copper nitrate, and dissolve them In deionized water, stir with a magnetic stirrer for 10 minutes to dissolve completely;

[0061] ②Dry the prepared solution at 80°C for 2 hours, then put it into a muffle furnace for calcination, the calcination temperature is 800 ℃, the calcination time is 2 hours, and the denitration catalyst can be obtained after natural cooling. The catalyst was then ground into a powder with an average particle size of 0.1 μm.

[0062] 2. Preparation of catalytic functional bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com