Friction material and preparation method thereof

A technology of friction materials and raw materials, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of complex manufacturing process, serious time consumption of consumables, high production cost, etc., and achieve improved application range, low processing cost, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

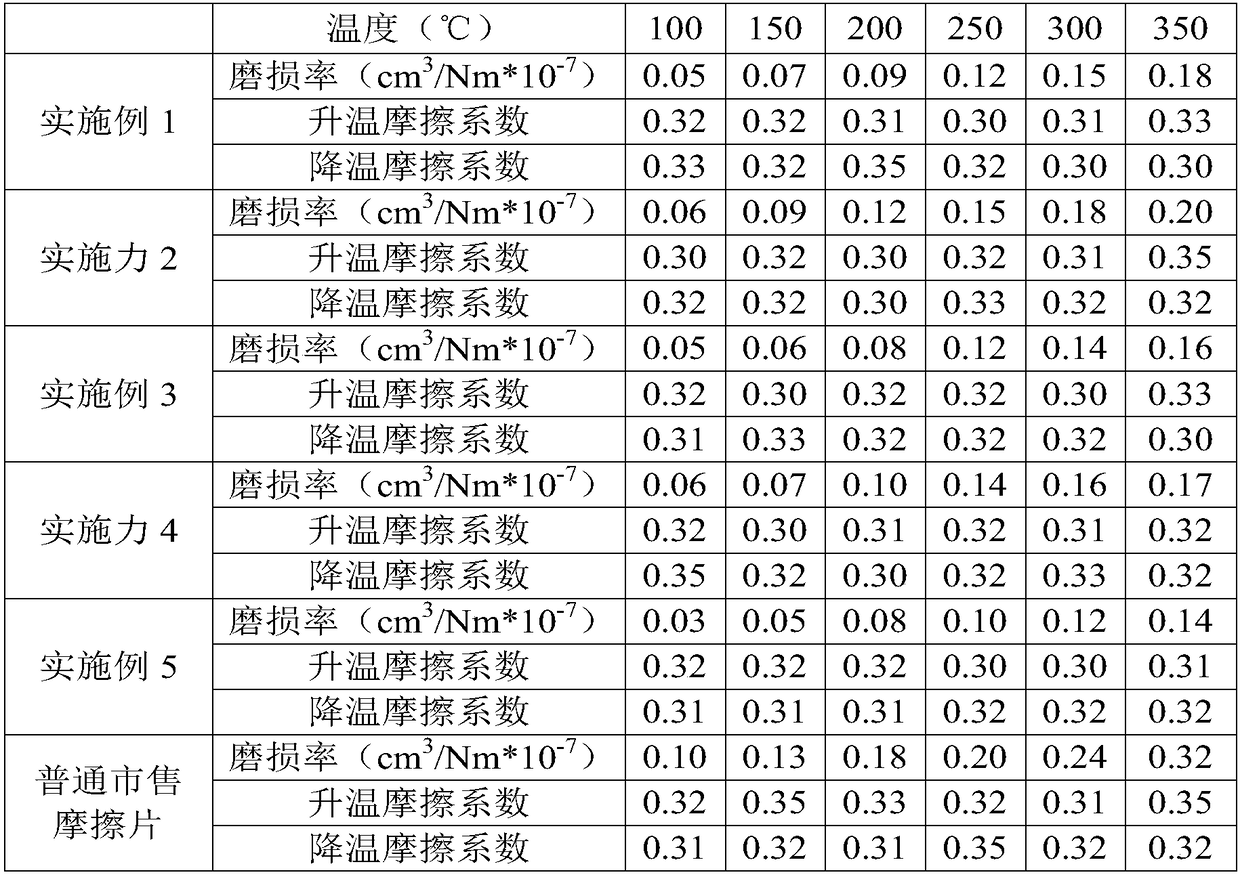

Examples

Embodiment 1

[0035] a friction material

[0036] Raw material and ingredient composition: (unit: g)

[0037] Synthetic fiber 200g, magnesium oxide 10g, aluminum oxide 10g, barium sulfate 200g, boron oxide 20g, sodium bicarbonate 20g, tert-butyl hydroquinone 10g, ethanol 10g, structural enhancer 20g.

[0038] The synthetic fiber in the above raw material composition is polyoxyethylene fiber; the weight ratio of styrene-butadiene rubber, friction powder, iron oxide and graphite in the structural reinforcing agent is: 1:2:1.5:2.

[0039] Prepared by:

[0040] S10, dissolving the tert-butyl hydroquinone in the ethanol of the weight part to form an ethanol solution of tert-butyl hydroquinone, adding the weight in the ethanol solution of tert-butyl hydroquinone Shake the polyoxyethylene fiber in the shaker for 0.5h, let it stand for 20min after shaking, filter after standing, and dry for 3h at a temperature of 85°C to obtain a modified polyoxyethylene fiber;

[0041] In the above operation, the...

Embodiment 2

[0046] a friction material

[0047] Raw material and ingredient composition: (unit: g)

[0048] 400g of synthetic fibers, 30g of magnesium oxide, 30g of aluminum oxide, 300g of barium sulfate, 60g of boron oxide, 30g of sodium bicarbonate, 60g of tert-butyl hydroquinone, 30g of ethanol, and 50g of structural enhancer.

[0049] The synthetic fiber in the above raw material composition is polybutylene terephthalate fiber; the weight ratio of styrene-butadiene rubber, friction powder, iron oxide and graphite in the structural reinforcing agent is: 1:2:1.5:2.

[0050] Prepared by:

[0051] S10, dissolving the tert-butyl hydroquinone in the ethanol of the weight part to form an ethanol solution of tert-butyl hydroquinone, adding the weight in the ethanol solution of tert-butyl hydroquinone Parts of polybutylene terephthalate fibers were shaken in a shaker for 1 hour, left to stand for 30 minutes after shaking, filtered after standing, and dried at a temperature of 95°C for 4 hour...

Embodiment 3

[0057] a friction material

[0058] Raw material and ingredient composition: (unit: g)

[0059] 250g of synthetic fibers, 10g of magnesium oxide, 20g of aluminum oxide, 240g of barium sulfate, 40g of boron oxide, 20g of sodium bicarbonate, 20g of tert-butyl hydroquinone, 10g of ethanol, and 20g of structural enhancer.

[0060] The synthetic fiber in the above raw material composition is polyacrylate fiber; the weight ratio of styrene-butadiene rubber, friction powder, iron oxide and graphite in the structural reinforcing agent is: 1:2:1.5:2.

[0061] Prepared by:

[0062] S10, dissolving the tert-butyl hydroquinone in the ethanol of the weight part to form an ethanol solution of tert-butyl hydroquinone, adding the weight in the ethanol solution of tert-butyl hydroquinone 1 part of polyacrylate fiber was shaken in a shaker for 0.6h, left to stand for 25min after shaking, filtered after standing, and dried at a temperature of 90°C for 3.5h to obtain modified polyacrylate fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com