Composite coating

A coating and nano-silica technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of reducing surface friction, poor stain resistance, easy to generate static electricity, etc., to reduce wind resistance, The effect of improving the smoothness of the paint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

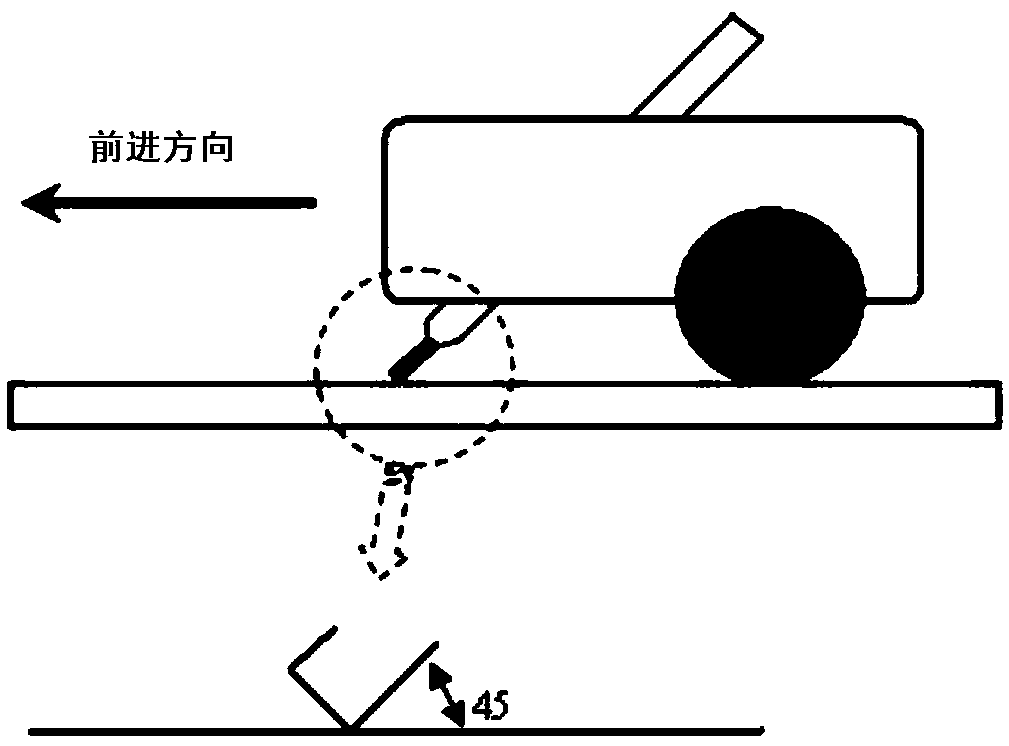

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

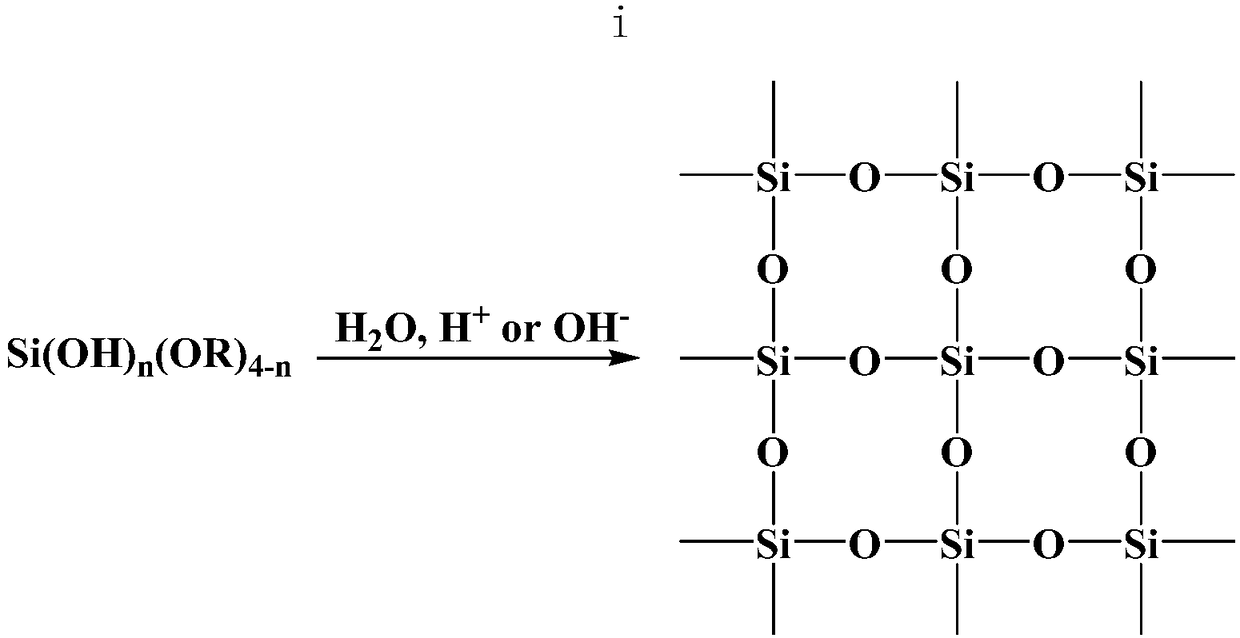

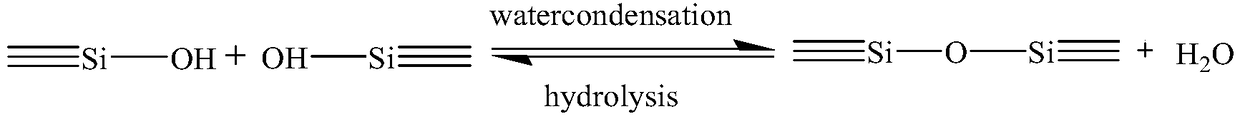

[0016] See attached Figure 1-3 , combined coating of the present invention, by weight percentage, comprises following composition: nano silicon oxide 15~30%, nano aluminum oxide 15~30%, nano zirconia 15~30%, auxiliary agent 5~10%, methacrylic acid 15-30% of similar cross-linking agent, and the rest is hydroxyl active silicone.

[0017] 20% of the nano-silica, 20% of the nano-alumina, 20% of the nano-zirconia, 5% of additives, 15% of methacrylic cross-linking agent, and 20% of hydroxyl active silicone.

[0018] In practical applications, the process technology adopts the manufacturing technology of organic and inorganic composites (Hybrid Ceramic Polymer Technology), which is a new composite that combines the characteristics of organic and inorganic substances. The advantages of organic substances are easy construction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com