Method for preparing electrospun nanofiber reinforced silica aerogel

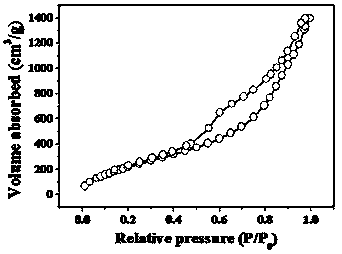

A nanofiber and silica technology, applied in the field of reinforcing composite silica aerogel blocks, can solve the problems of large solvent consumption, dangerous drying method, low strength, etc., and achieve uniform fiber diameter distribution and excellent physical properties. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Molar ratio of raw materials: TEOS: ethanol: water = 1:10:0.4, mix 5 ml of TEOS with 13 ml of absolute ethanol, then add 1.8 ml of water, add hydrochloric acid solution to adjust the pH of the mixed solution to 3~4, Stir continuously for 12 h to promote the hydrolysis of the silicon source; dissolve the polyacrylonitrile with dimethylformamide, and spin the electrospinning polyacrylonitrile nanofibers. The spinning conditions: the voltage is 15 kV, the flow rate is 1 ml / h, and the receiving distance is 15 cm, the spinning time is 1 h, the electrospun polyacrylonitrile nanofibers are collected and dispersed through silica sol, and a certain amount of ammonia is added to make the composite silica sol form a gel. Then put the wet gel in anhydrous ethanol solution for aging. The aging temperature is 50 ℃. After aging, the gel sample is immersed in the solution and the volume ratio is TMCS: anhydrous ethanol: n-hexane = 1:2:8. Modified in the solution for 2 days, in which the...

Embodiment 2

[0033] Molar ratio of raw materials: TEOS: ethanol: water=1:15:0.6, mix 5 ml of TEOS with 19.5 ml of absolute ethanol, add 2.7 ml of water, add hydrochloric acid solution to adjust the pH of the mixed solution to 3~4, continue Stir for 24h to promote the hydrolysis of the silicon source; dissolve the polymethyl methacrylate with dimethylformamide and electrospun the polymethyl methacrylate nanofibers. Spinning conditions: voltage is 18 kV, flow rate is 1 ml / h , The receiving distance is 15 cm, the spinning time is 3 h, the electrospun polymethyl methacrylate nanofibers are collected and dispersed by silica sol, and a certain amount of ammonia is added to make the composite silica sol form a gel . Then put the wet gel in anhydrous ethanol solution for aging. The aging temperature is 50 ℃. After aging, the gel sample is immersed in the solution. The volume ratio is HMDS: anhydrous ethanol: n-hexane = 1:1:8. Modified in the solution for 2 days, in which the HMDS is 5 ml, wash off...

Embodiment 3

[0037] Raw material molar ratio: TMOS: ethanol: water = 1:10:0.4, mix 3.3 ml of TMOS with 13 ml of absolute ethanol, then add 1.8 ml of water, add hydrochloric acid solution to adjust the pH of the mixed solution to 3~4, continue Stir for 24h to promote the hydrolysis of the silicon source; dissolve polyamide with dimethylformamide, and spin the electrospinning polyamide nanofiber. Spinning conditions: voltage 18 kV, flow rate 2ml / h, receiving distance 15 cm, spinning The time is 1 h. The electrospun polyamide nanofibers are collected and dispersed through silica sol, and a certain amount of ammonia is added to make the composite silica sol form a gel. Then put the wet gel in anhydrous ethanol solution for aging. The aging temperature is 60 ℃. After aging, the gel sample is immersed in the solution and the volume ratio is TMCS: anhydrous ethanol: n-hexane = 1:3:8. Modified in the solution for 1 day, in which the TMCS is 5 ml, wash off the modified solution with n-hexane, and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com