Polypyrrole surface-modified one-dimensional silicon-based gas-sensing material and preparation method thereof

A technology for surface modification and gas-sensing materials, applied in the field of room-temperature working gas-sensing materials, can solve the problems of limited application and low sensitivity, and achieve the effects of improving diffusion capacity, increasing sensitivity, and reducing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

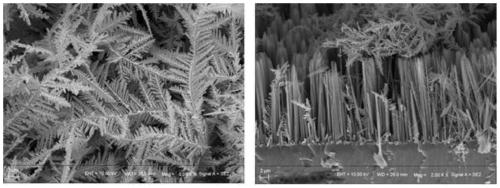

Image

Examples

Embodiment 1

[0032] (1) Cleaning of monocrystalline silicon wafers

[0033] Silicon wafers were ultrasonically cleaned in hydrogen peroxide (10wt% hydrogen peroxide aqueous solution) and concentrated sulfuric acid (98wt% by mass) at a volume ratio of 4:1 for 10 minutes, and then placed in acetone solvent, absolute ethanol, and deionized water successively. Ultrasonic cleaning was performed for 5-10 minutes to remove surface oil and organic impurities, and then dried thoroughly in an infrared oven.

[0034] (2) Configure chemical etching solution

[0035] Dissolving silver nitrate in hydrofluoric acid aqueous solution, the concentration of hydrofluoric acid in the obtained solution is 5M, and the concentration of silver nitrate is 0.025M. (3) Metal-assisted chemical etching

[0036] Putting the silicon wafer into the solution prepared in step (2) for etching, the etching time is 150 min.

[0037] (4) Clean the etched silicon wafer

[0038] After the silicon chip obtained in step (3) is ...

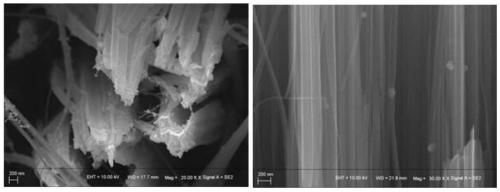

Embodiment 2

[0050] (1) Cleaning of monocrystalline silicon wafers

[0051] Silicon wafers were ultrasonically cleaned in hydrogen peroxide (10wt% hydrogen peroxide aqueous solution) and concentrated sulfuric acid (98wt% by mass) at a volume ratio of 4:1 for 10 minutes, and then placed in acetone solvent, absolute ethanol, and deionized water successively. Ultrasonic cleaning was performed for 5-10 minutes to remove surface oil and organic impurities, and then dried thoroughly in an infrared oven.

[0052] (2) Configure chemical etching solution

[0053] Dissolving silver nitrate in hydrofluoric acid aqueous solution, the concentration of hydrofluoric acid in the obtained solution is 3M, and the concentration of silver nitrate is 0.02M.

[0054] (3) Metal-assisted chemical etching

[0055] Putting the silicon wafer into the solution prepared in step (2) for etching, the etching time is 180 min.

[0056] (4) Clean the etched silicon wafer

[0057] After the silicon chip obtained in step...

Embodiment 3

[0069] (1) Cleaning of monocrystalline silicon wafers

[0070] Silicon wafers were ultrasonically cleaned in hydrogen peroxide (10wt% hydrogen peroxide aqueous solution) and concentrated sulfuric acid (98wt% by mass) at a volume ratio of 4:1 for 10 minutes, and then placed in acetone solvent, absolute ethanol, and deionized water successively. Ultrasonic cleaning was performed for 5-10 minutes to remove surface oil and organic impurities, and then dried thoroughly in an infrared oven.

[0071] (2) Configure chemical etching solution

[0072] Dissolving silver nitrate in hydrofluoric acid aqueous solution, the concentration of hydrofluoric acid in the obtained solution is 6M, and the concentration of silver nitrate is 0.03M.

[0073] (3) Metal-assisted chemical etching

[0074] Putting the silicon wafer into the solution prepared in step (2) for etching, the etching time is 90 minutes.

[0075] (4) Clean the etched silicon wafer

[0076] After the silicon chip obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com