High-temperature-resistant tubular armored platinum resistor and application thereof

A platinum resistance, high temperature resistant technology, applied in the field of thermal control facilities, can solve the problem of not being able to meet the temperature resistance requirements of the thruster, achieve good high temperature oxidation resistance and heat resistance, ensure heat resistance and life, and low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

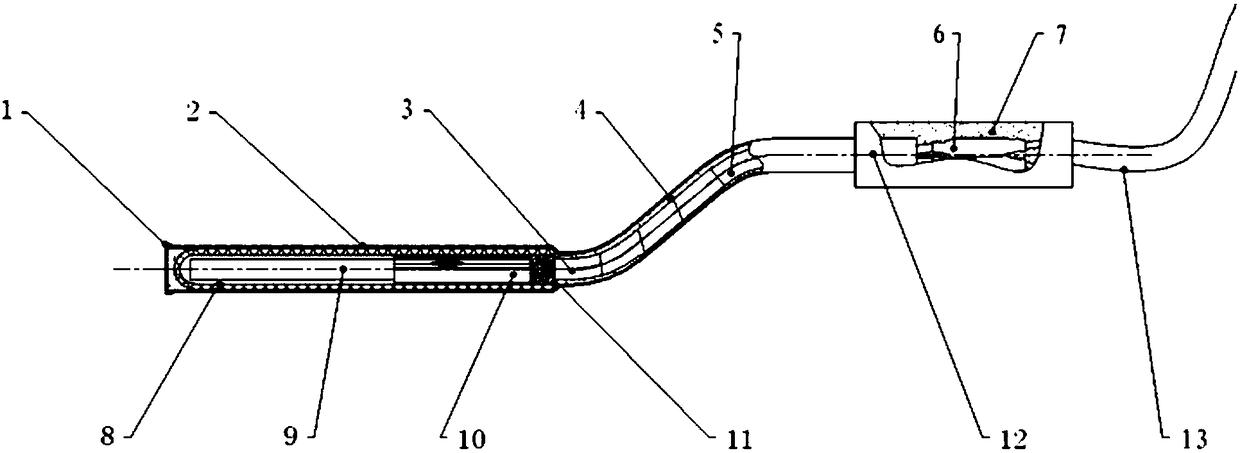

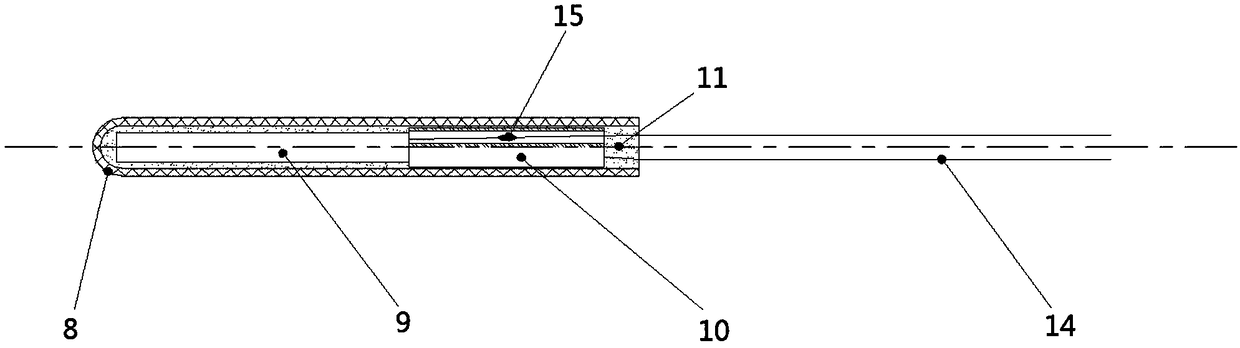

[0035] In this embodiment, the armored platinum resistor required for a 5N space thruster is taken as an example.

[0036] The German Heraeus wire-wound PT100 platinum resistance element is selected, its size is Φ1.5×15mm, and its precision is 2B. First, inspect the appearance and size of the platinum resistance element, and measure its freezing point resistance to ensure that the element is a qualified product.

[0037] Cut a piece of platinum wire (degraded state) with a length of 70mm and a diameter of Φ0.3mm as the platinum resistance transition line, and weld the pins of the platinum resistance element and the platinum resistance transition line together by spot welding; use a CNC dicing machine to cut Φ2. The 8mm double-hole ceramic tube is 12mm, and the solder joints are protected in the double-hole ceramic tube; the platinum resistance element and the double-hole ceramic tube are put into a platinum resistance protection tube with one end sealed, and the outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com