Method used for manufacturing composite wear-resistant hammerhead from hard alloy through high temperature casting

A technology of cemented carbide and steel-bonded cemented carbide, which is applied in the field of high-temperature inlay-cast cemented carbide to manufacture composite wear-resistant hammer heads, which can solve the problem that the hammer handle and cemented carbide are easy to fall off, and the cemented carbide and hammer matrix are not well bonded. The problems such as fastness and pouring combination are difficult, and the effect of low cost, good anti-oxidation performance and simple process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

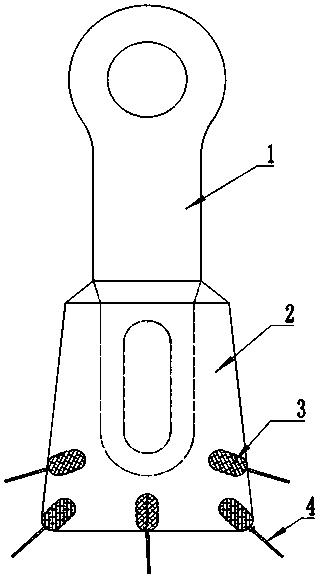

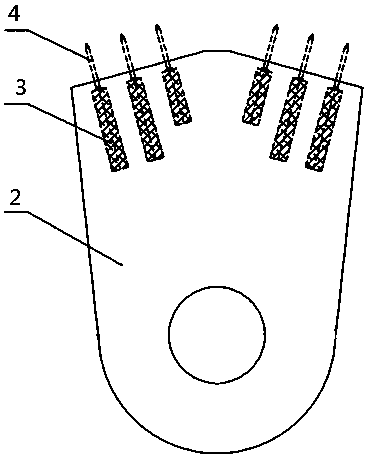

[0038] Embodiment 1, the unit weight of the hammer head in this embodiment is 10kg, and the hammer handle is pre-cast with low-alloy high-strength steel, wherein the mass fraction of the chemical composition of the low-alloy high-strength steel is C 0.32-0.38%, Mn 1.6 -1.9%, Si 1.45-1.75%, V 0.10-0.20%, the balance is Fe, the mechanical properties are σb 1840Mpa, σ0.2 1580MPa; the alloy for inlay casting is titanium carbide-based steel-bonded carbide TM65, and its shape is Rod, size The center of one end of the alloy rod is welded with a fixed pin, the size is All are produced by our company; the mass parts of its components are Cr0.6-1.0%, Mo0.8-1.4%, C 0.8-1.0%, MnFe powder 4.0-7.0%, TiC 32.0-35.0%, and the balance is Fe ;Mechanical and physical properties: density 6.4g / ㎝ 3 , sintered hardness HRC 63-65, bending strength 1500-1800MPa, impact toughness 6.0-8.0J / ㎝ 2 The hammer head material that the present invention selects is ZG120Mn13Cr2 austenitic manganese steel; The...

Embodiment 2

[0040] Example 2, the overall hammer base is high manganese steel, with a single weight of 110kg, and the casting material of the hammer is titanium carbide-based steel-bonded hard alloy TM65, the shape is rod-shaped, and the size is and Two types, the center of one end of the rod is welded with a dowel, the size is The above materials are produced by our company. The composition and mass fraction of steel-bonded cemented carbide TM65 are: Cr 0.6-1.0%, Mo 0.8-1.4%, C 0.8-1.0%, MnFe powder 4.0-7.0%, TiC 32.0-35.0%, and the balance is Fe; The mechanical and physical properties are: density 6.4g / ㎝ 3 , sintered hardness HRC 63-65, bending strength 1500-1800MPa, impact toughness 6.0-8.0J / ㎝ 2 ; Hammer base material of the present invention is ZG120Mn13Cr2 austenitic manganese steel;

[0041] The present embodiment utilizes the foamed plastic mold to realize high-temperature inlay casting. The quality of the inlaid casting hammer head is 110 kg, and the specific implementatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com