Low-power resistive switching memory cell based on doped strontium titanate film and its preparation method and application

A technology of resistive switch and storage unit, applied in the field of information storage, can solve the problems of no major breakthrough in reducing power consumption, large set/reset voltage, small on/off current ratio, etc., so as to reduce power consumption and reduce set /Reset voltage, effect of increasing ON/OFF current ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

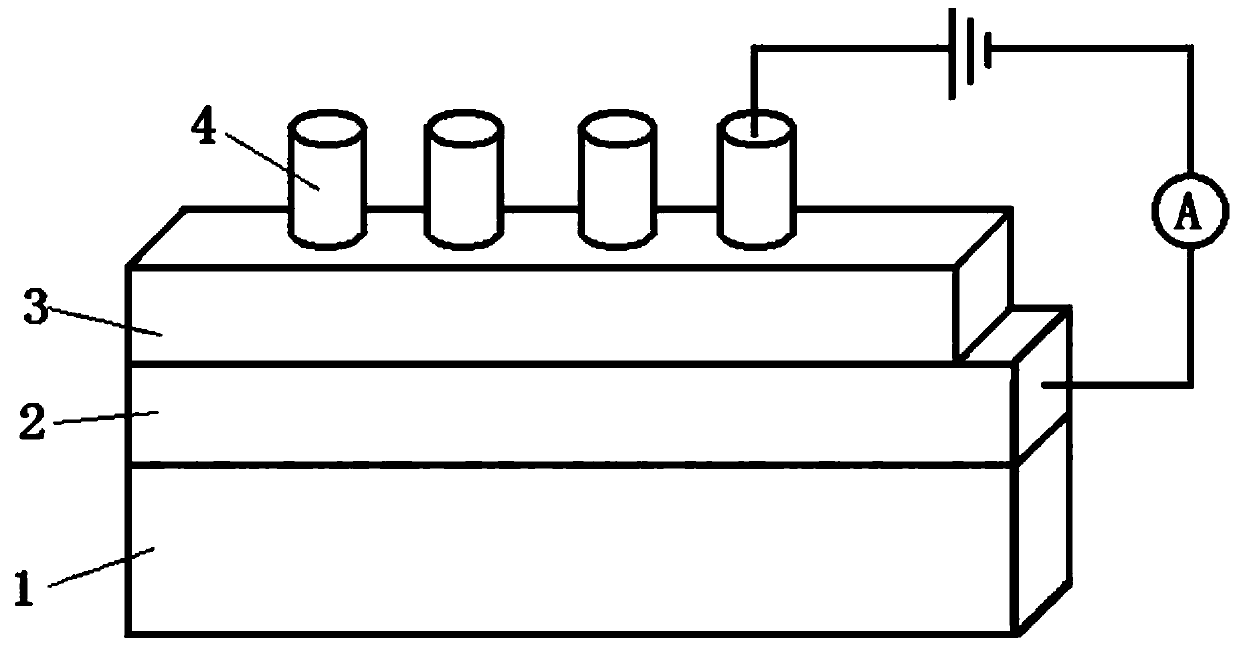

[0036] Embodiment 1, a method for preparing a low power consumption resistive switch memory cell based on a doped strontium titanate thin film, which includes the following steps:

[0037] Step 1: Select a conventional semiconductor Si single crystal substrate as the substrate, and prepare the lower electrode layer by DC magnetron sputtering in an argon atmosphere. The process conditions are: metal Pt is used as the sputtering target, and the sputtering gas is Argon gas, the sputtering pressure is 2.7Pa, the sputtering temperature is 350°C, the sputtering power is 35W, a bias voltage of -100V is applied, and the growth rate is 10-15nm / min;

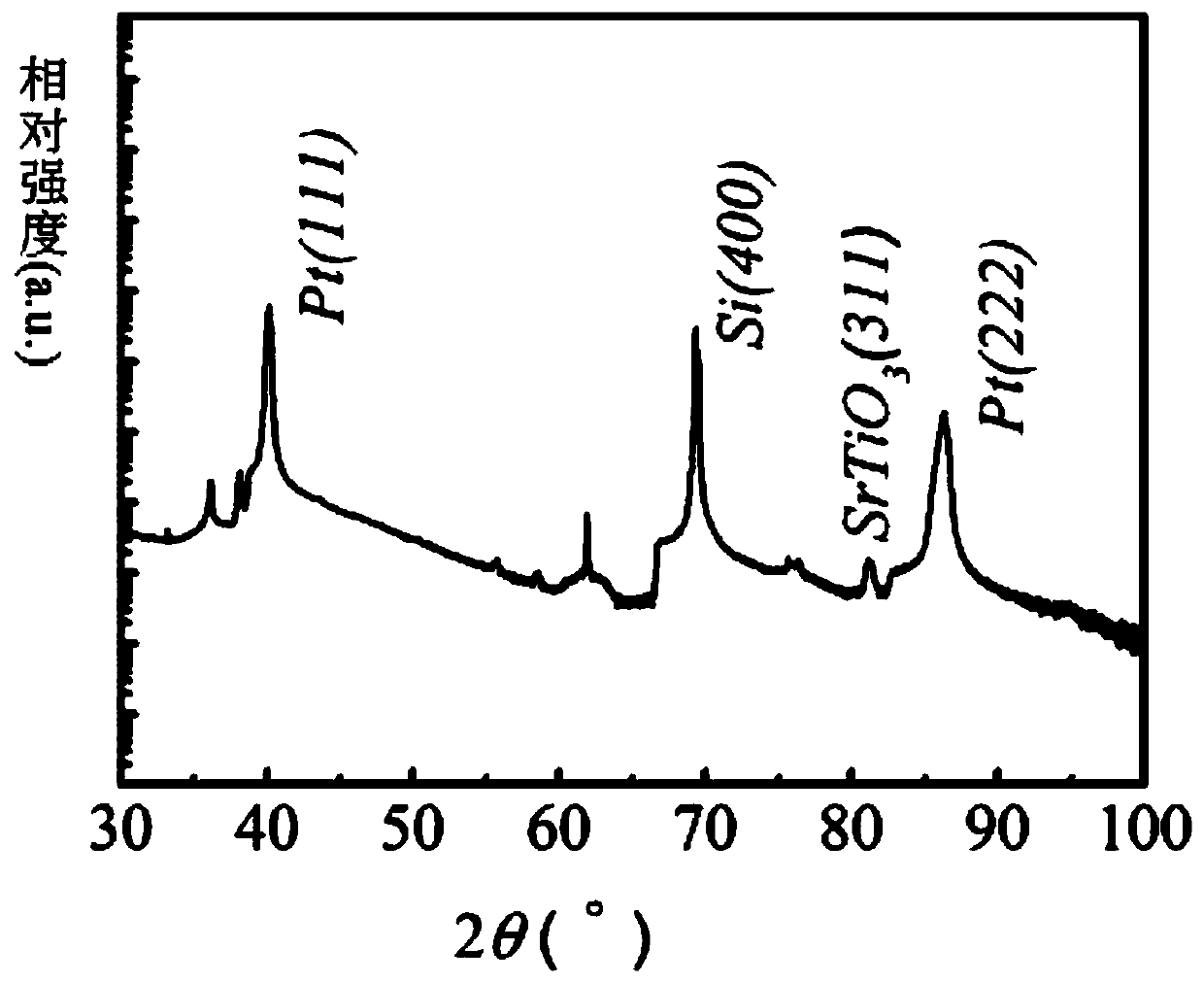

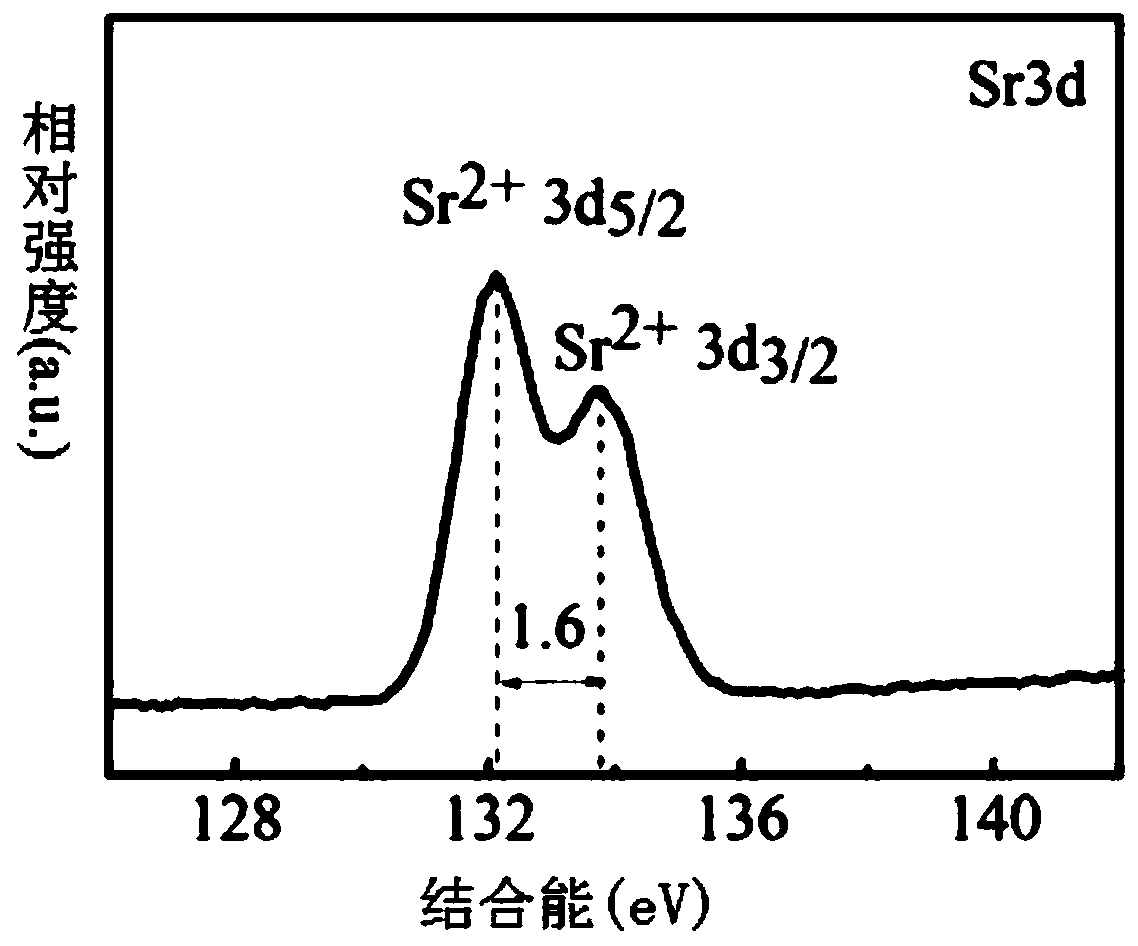

[0038] In step 2, the substrate with the lower electrode layer is preheated at a temperature of 600° C., and then the Fe / strontium titanate thin film resistive layer is prepared on the lower electrode layer by radio frequency magnetron sputtering. The process conditions are: : Strontium titanate ceramic target with a purity of 99.9% and a ...

Embodiment 2

[0041] Embodiment 2, a method for preparing a low power consumption resistive switch memory cell based on a doped strontium titanate thin film, which includes the following steps:

[0042] Step 1: Select a conventional semiconductor Si single crystal substrate as the substrate, and prepare the lower electrode layer by DC magnetron sputtering in an argon atmosphere. The process conditions are: metal Pt is used as the sputtering target, and the sputtering gas is Argon gas, the sputtering pressure is 2Pa, the sputtering temperature is 300°C, the sputtering power is 25W, a bias voltage of -100V is applied, and the growth rate is 10-15nm / min;

[0043] In step 2, the substrate with the lower electrode layer is preheated at a temperature of 800° C., and then the Fe / strontium titanate thin film resistive layer is prepared on the lower electrode layer by radio frequency magnetron sputtering. The process conditions are: : Strontium titanate ceramic target with a purity of 99.9% and a Fe...

Embodiment 3

[0046] Embodiment 3, a method for preparing a low power consumption resistive switch memory cell based on a doped strontium titanate thin film, which includes the following steps:

[0047] Step 1: Select a conventional semiconductor Si single crystal substrate as the substrate, and prepare the lower electrode layer by DC magnetron sputtering in an argon atmosphere. The process conditions are: metal Pt is used as the sputtering target, and the sputtering gas is Argon gas, the sputtering pressure is 1Pa, the sputtering temperature is 400°C, the sputtering power is 45W, a bias voltage of -100V is applied, and the growth rate is 10-15nm / min;

[0048] In step 2, the substrate with the lower electrode layer is preheated at a temperature of 300° C., and then the Fe / strontium titanate thin film resistive layer is prepared on the lower electrode layer by radio frequency magnetron sputtering. The process conditions are: : Strontium titanate ceramic target with a purity of 99.9% and a Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com