Method for preparing calcium carbonate by directly extracting microbial strains from soil

A microbial strain, calcium carbonate technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of increased calcium carbonate yield, consumption, and multiple manpower and material resources, and achieve high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

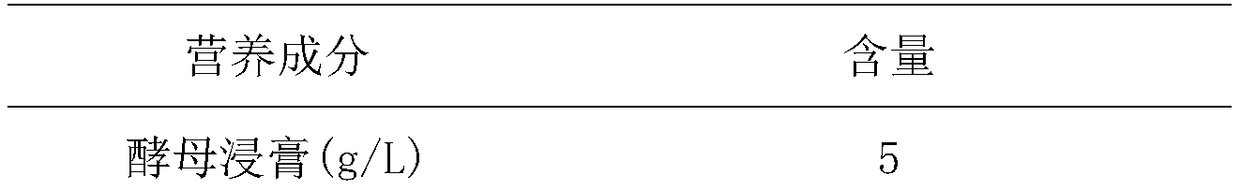

Embodiment 1

[0034] A method for directly extracting microbial strains from soil to prepare calcium carbonate, the main steps of the method are:

[0035] 1) Collect soil samples with an organic matter content of 20-30g / kg, take several soil samples within a depth of 5-30cm, put the soil samples into a sterilized sample bag, seal them and store them in a refrigerator at 4°C.

[0036] 2) Extract and isolate Bacillus species from soil samples.

[0037] a) Weigh 5g of soil samples respectively, pour the weighed soil samples into 90ml sterile water in the ultra-clean workbench, shake fully to make the soil samples suspend, and let stand at room temperature for 4 hours, which is 10 -1 Diluent.

[0038] b) Use a micropipette to take 0.5ml of the treated soil supernatant in a test tube filled with 4.5ml of sterile water, shake it, and let the bacteria solution mix evenly, which is 10 -2 Diluent. draw 10 -2 Dilute 0.5ml, transfer it into a test tube filled with 4.5ml sterile water, oscillate, l...

Embodiment 2

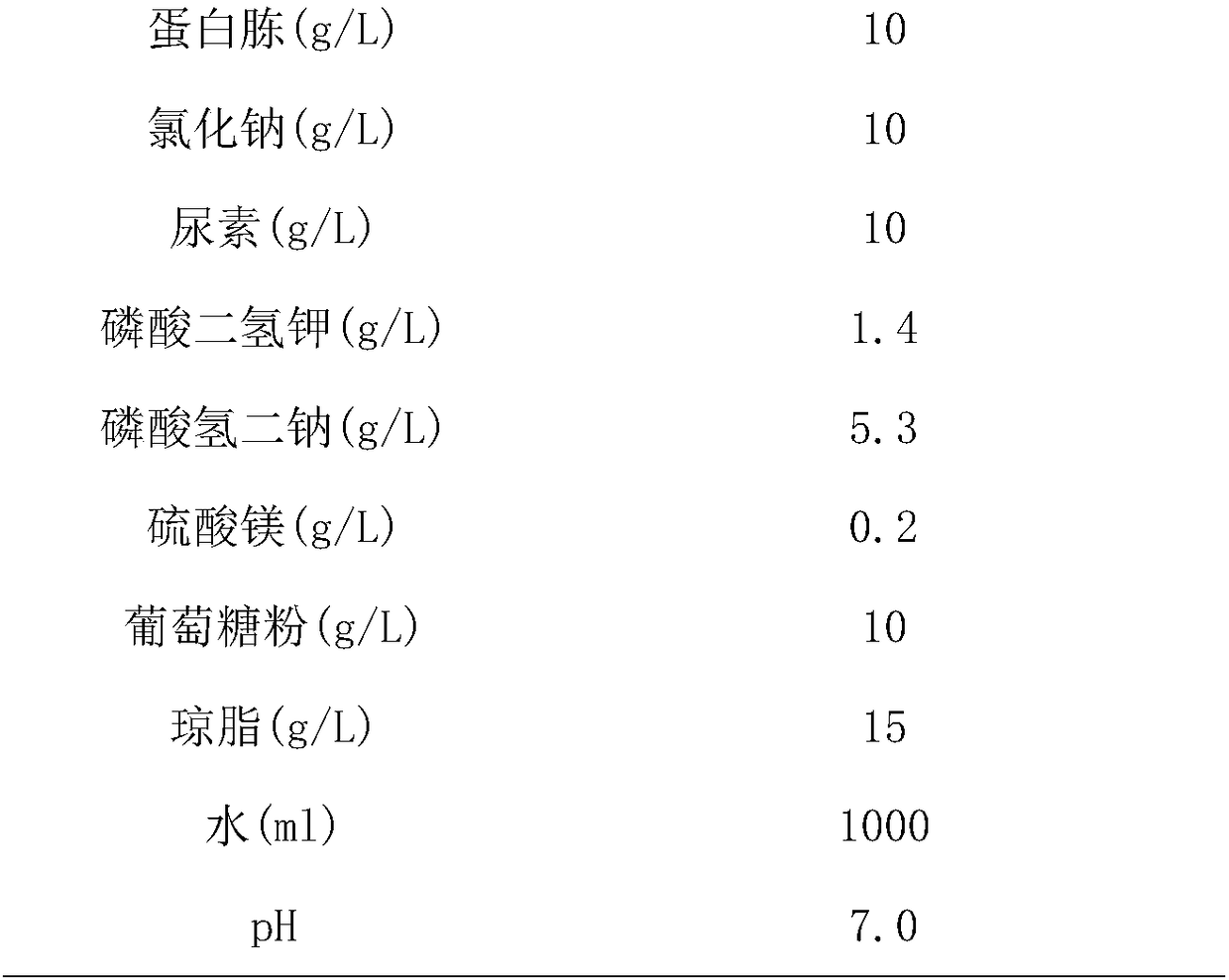

[0049]The same method as in Example 1 was used to extract and purify the Bacillus species in the soil to finally obtain the purified bacterial strain. The culture medium shown in Table 1 was prepared to propagate the isolated Bacillus strains; the strains obtained after 3 times of separation and purification were cultured for 36 hours, and the absorbance reached 1.5. Finally, the gel solution is prepared together with the strain solution to induce the strain to precipitate calcium carbonate. Mix equal volumes of bacterial solution and gelling solution (recipe in Table 3) into a 50ml centrifuge tube, place the centrifuge tube in a constant temperature air bath incubator at 30°C for 5 days, and filter the mixed solution to obtain microbially induced carbonic acid The calcium precipitation yield was 60%.

[0050] Table 3 gel formula (1000mL)

[0051]

Embodiment 3

[0053] Adopt the same method as in Example 1 to extract and purify the Bacillus species in the soil, the difference is that urea (20g / L) and nickel sulfate (20g / L) are added to the medium as a solid selective medium to finally obtain the purified bacterial strain. The culture medium shown in Table 1 was prepared to propagate the isolated Bacillus strains; the strains obtained after 3 times of separation and purification were cultured for 36 hours, and the absorbance reached 1.4. Finally, the gel solution is prepared together with the strain solution to induce the strain to precipitate calcium carbonate. Mix equal volumes of bacterial liquid and gelling liquid (recipe in Table 2) into a 50ml centrifuge tube, place the centrifuge tube in a constant temperature air bath incubator at 30°C for 5 days, and filter the mixed liquid to obtain microbially induced carbonic acid The calcium precipitation yield was 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com