Compound detergent sheet

A technology of laundry tablet and laundry layer, applied in the directions of detergent powder/sheet/sheet, detergent compounding agent, detergent composition, etc., can solve the problems of easy loss of function, instability, etc. The effect of improving stability and improving washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

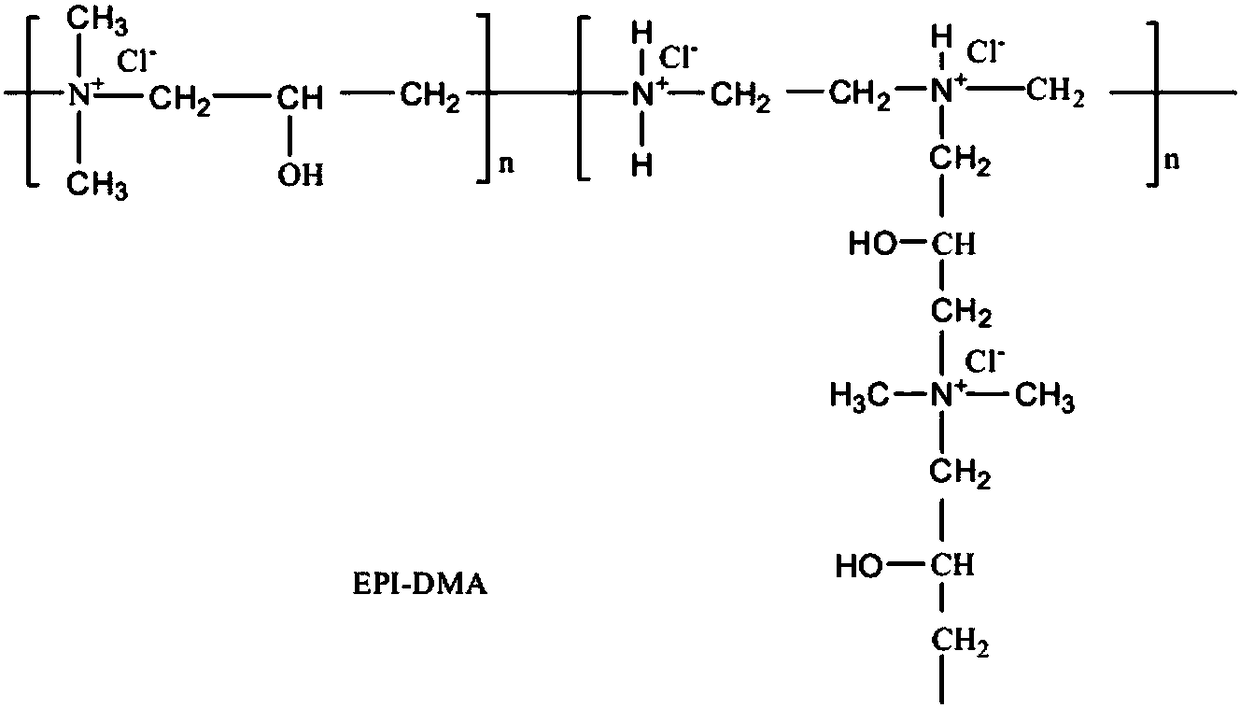

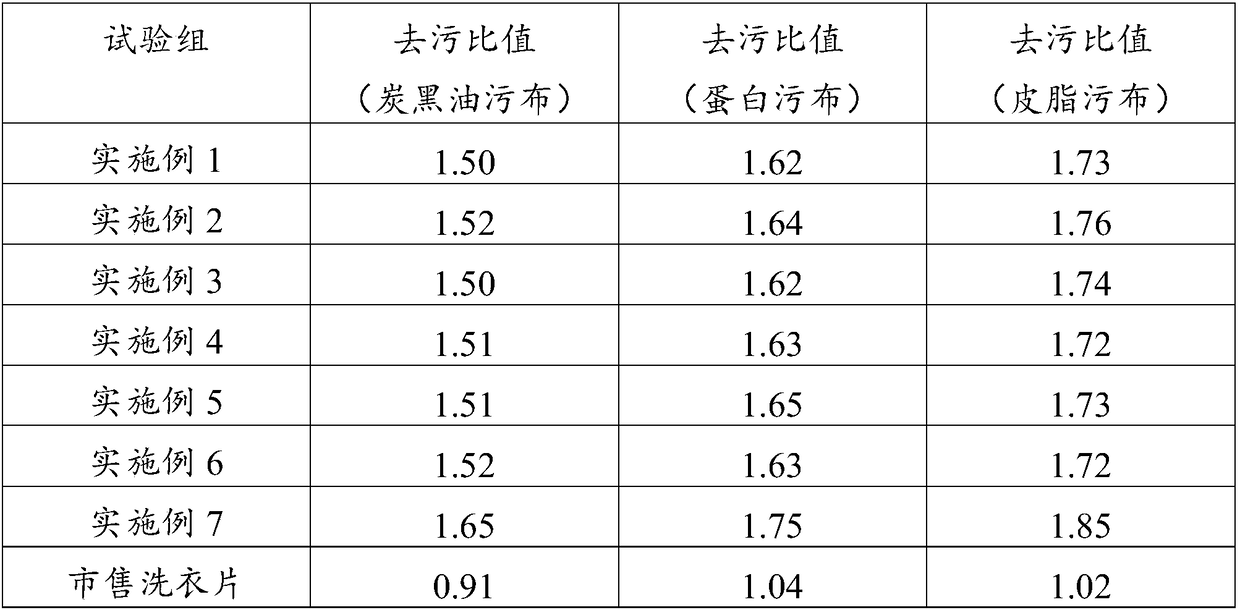

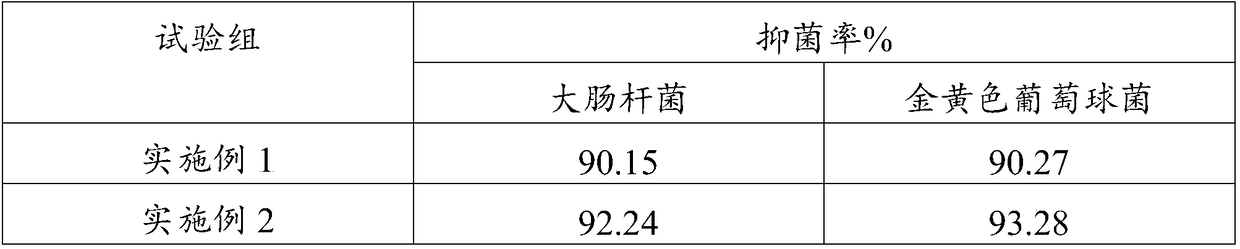

Embodiment 1

[0031] A composite laundry sheet, comprising a fiber layer, a first laundry layer, an active enzyme layer and a second laundry layer, the first laundry layer is set on one side of the fiber layer, the second laundry layer is set on the The first laundry layer is away from the side of the fiber layer, and the active enzyme layer is arranged between the first laundry layer and the second laundry layer; the first laundry layer includes by weight: fatty alcohol 10 parts of polyoxyethylene ether, 10 parts of sodium fatty alcohol polyoxyethylene ether sulfonate, 2 parts of polyepichlorohydrin dimethylamine, 0.02 parts of disodium edetate, 1 part of sorbitol, 2 parts of thickener , 0.5 parts of film-forming agent, 0.2 part of forming aid, 0.1 part of pH regulator, 40 parts of deionized water; the second laundry layer includes by weight: 10 parts of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene 10 parts of sodium vinyl ether sulfonate, 0.02 parts of disodium edeta...

Embodiment 2

[0033] A composite laundry sheet, comprising a fiber layer, a first laundry layer, an active enzyme layer and a second laundry layer, the first laundry layer is set on one side of the fiber layer, the second laundry layer is set on the The first laundry layer is away from the side of the fiber layer, and the active enzyme layer is arranged between the first laundry layer and the second laundry layer; the first laundry layer includes by weight: fatty alcohol 12 parts of polyoxyethylene ether, 12 parts of sodium fatty alcohol polyoxyethylene ether sulfonate, 3 parts of polyepichlorohydrin dimethylamine, 0.05 parts of disodium edetate, 2 parts of sorbitol, 3 parts of thickener , 1 part of film-forming agent, 0.4 part of forming aid, 0.3 part of pH regulator, 20 parts of deionized water; the second laundry layer includes by weight: 12 parts of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene 12 parts of sodium vinyl ether sulfonate, 0.05 parts of disodium edetate...

Embodiment 3

[0035] A composite laundry sheet, comprising a fiber layer, a first laundry layer, an active enzyme layer and a second laundry layer, the first laundry layer is set on one side of the fiber layer, the second laundry layer is set on the The first laundry layer is away from the side of the fiber layer, and the active enzyme layer is arranged between the first laundry layer and the second laundry layer; the first laundry layer includes by weight: fatty alcohol 14 parts of polyoxyethylene ether, 14 parts of sodium fatty alcohol polyoxyethylene ether sulfonate, 4 parts of polyepichlorohydrin dimethylamine, 0.08 parts of disodium edetate, 2 parts of sorbitol, 3 parts of thickener , 1.5 parts of film-forming agent, 0.6 part of forming aid, 0.5 part of pH regulator, 30 parts of deionized water; the second laundry layer includes by weight: 14 parts of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene 14 parts of sodium vinyl ether sulfonate, 0.08 parts of disodium edet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com