Preparation of an Array Structured Transition Metal Selenide Electrode and Its Application in Electrolysis of Water

A transition metal, array structure technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of insufficient exposure of active sites, unfavorable mass transfer and electron transfer, inhibition of development and application, etc., to achieve excellent electrocatalytic decomposition Effects of water performance, controllability of synthesis process, and universality of synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first step is to treat the nickel sheet (NF) with hydrochloric acid, acetone, ethanol and water for 10 minutes. -15 minutes, use the same method to sequentially use acetone, ethanol and water for ultrasonic cleaning. Then dry the cleaned NF for the next step.

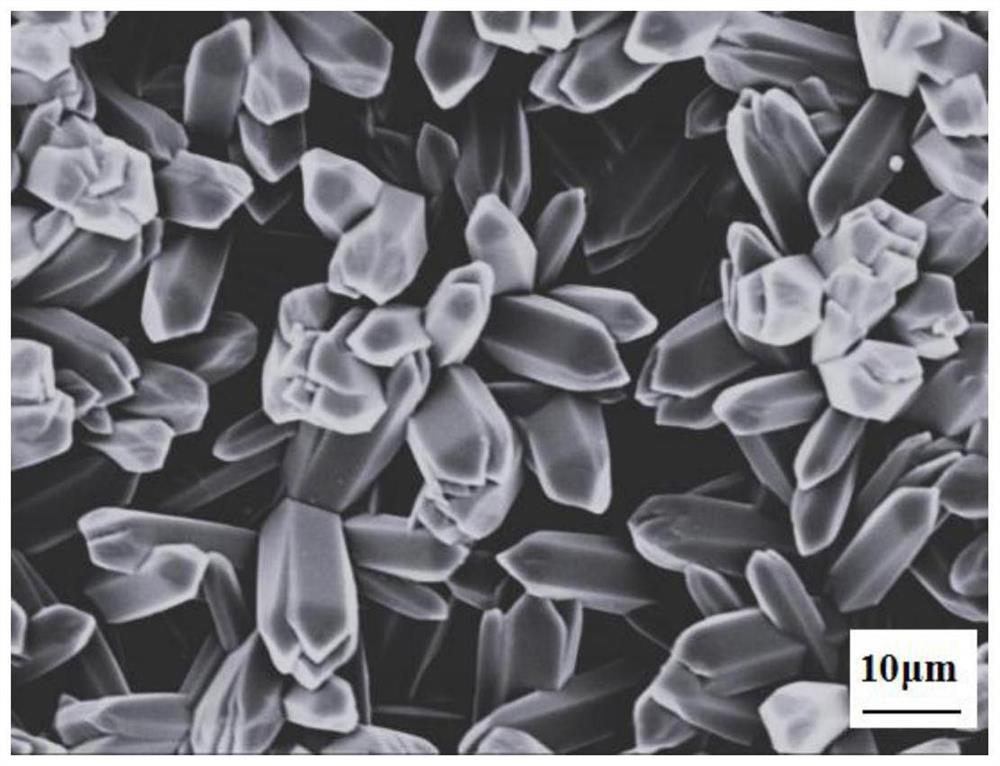

[0023] In the second step, NF is immersed in mother liquor B for hydrothermal reaction. Mother liquor B is 0.15g of 2,5-dihydroxyterephthalic acid and 0.7g of cobalt nitrate hexahydrate dissolved in 20ml of N,N-dimethylformamide and water mixed solution with ethanol. The volume ratio of N,N-dimethylformamide to water and ethanol is 1:1:1, and transferred into a 100ml reactor for hydrothermal reaction at 100°C for 15 hours. After the reaction, the NF-Co-MOF composite was obtained by washing with ethanol and N,N-dimethylformamide several times.

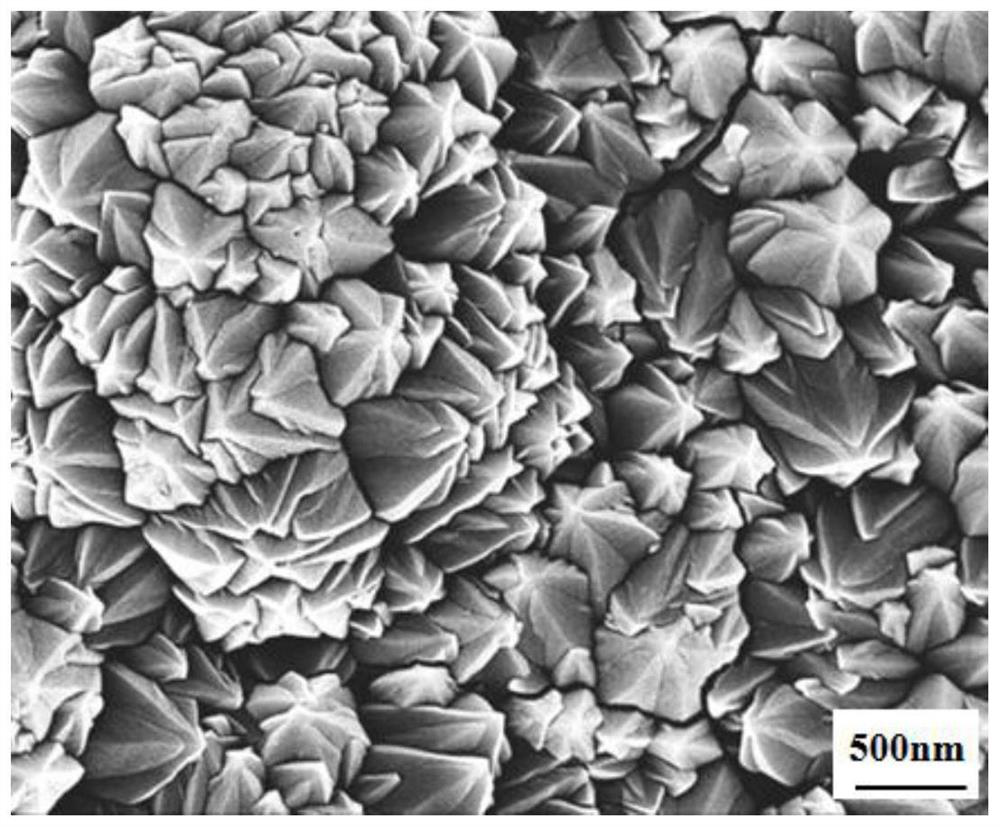

[0024] In the third step, 0.1-0.3g of selenium powder and the NF-Co-MOF composite material synthesized in the previous step are placed in a magnetic boat at the sam...

Embodiment 2

[0026] The first step is to pretreat the nickel sheet (NF) with hydrochloric acid, acetone, ethanol and water for 10 minutes. For 10-15 minutes, use the same method to sequentially use acetone, ethanol and water for ultrasonic cleaning. Then dry the cleaned NF for the next step.

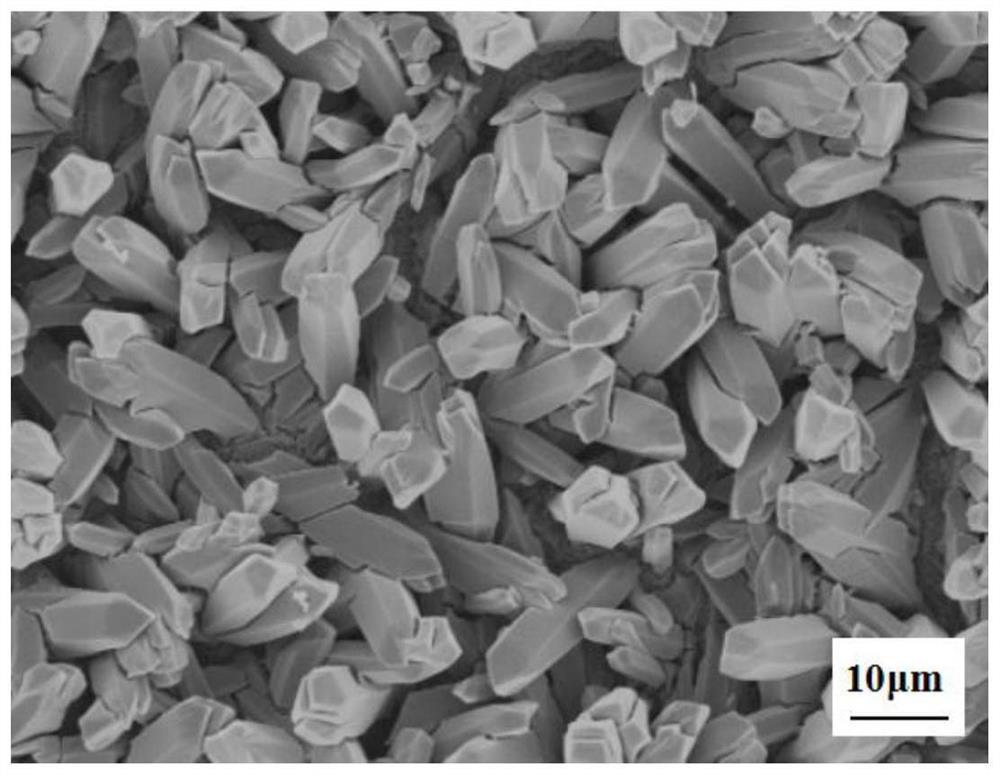

[0027] In the second step, NF is immersed in mother liquor B for hydrothermal reaction. Mother liquor B is 0.15g of 2,5-dihydroxyterephthalic acid and 0.7g of nickel nitrate hexahydrate dissolved in 20ml of N,N-dimethylformamide and water mixed solution with ethanol. The volume ratio of N,N-dimethylformamide to water and ethanol is 1:1:1, and transferred into a 100ml reactor for hydrothermal reaction at 100°C for 15 hours. After the reaction, the NF-Ni-MOF composite was obtained by washing with ethanol and N,N-dimethylformamide several times.

[0028] In the third step, 0.1-0.3g of selenium powder and the NF-Ni-MOF composite material synthesized in the previous step are placed in a magnetic boat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com