Packaging machine for mixed filling

A technology of mixed filling and filling machine, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of the influence of the uniformity of the mixed material and the increase in the difficulty of filling, so as to shorten the production cycle and improve production efficiency. Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

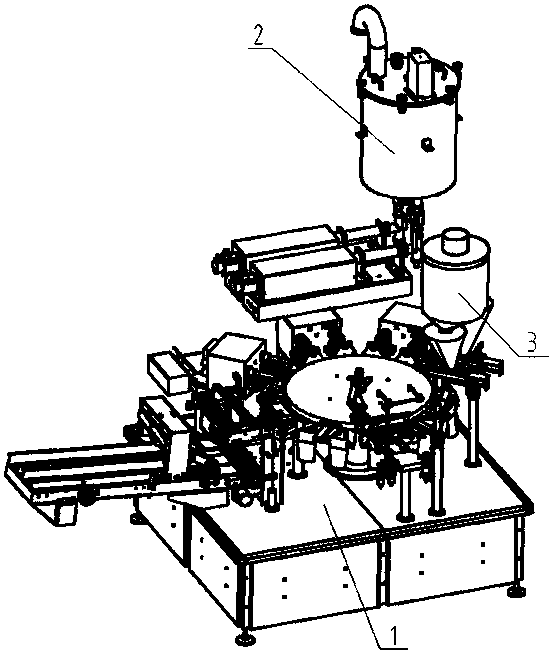

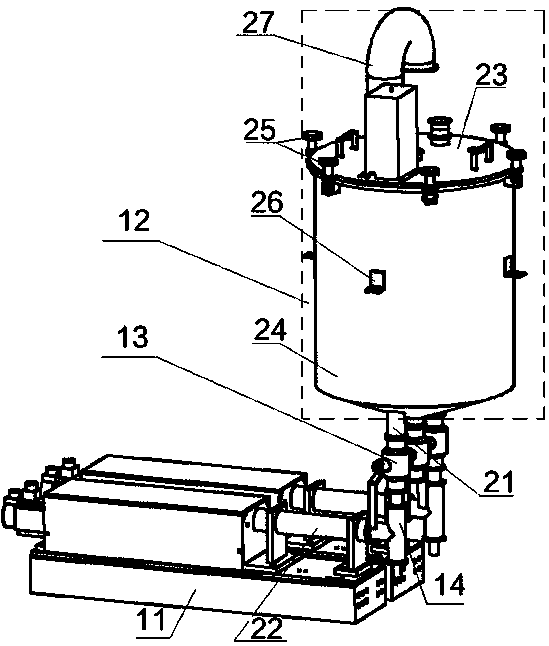

[0023] refer to Figure 1-Figure 4 , the mixed filling and packaging machine of this embodiment, which includes a double-row packaging machine main body 1, a support frame, a liquid filling system 2 and a particle container filling system 3, and the support frame is fixed on the double-row packaging machine main body 1 , the liquid filling system 2 and the particle container filling system 3 are fixed side by side on the support frame, and the liquid filling system 2 includes a filling machine 11, a liquid storage tank 12, a control valve 13, a filling three Through 14, the liquid storage tank 12 is connected with the filling machine 11 through a delivery pipe.

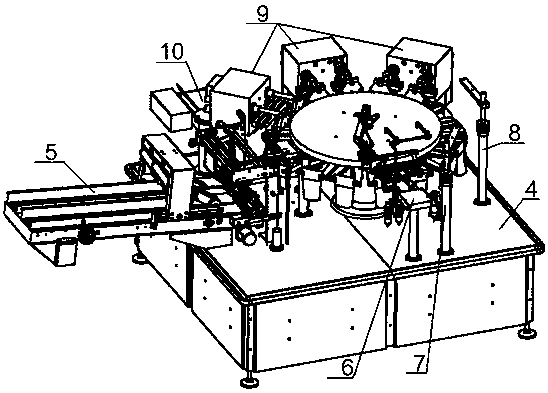

[0024] The main body of the double-lane packaging machine includes a frame 4, on which a rotating disc and a horizontal bagging device 5, a bag opening device 6, a primary blanking device 7, and a secondary blanking device are arranged around the circumference of the rotary disc. Device 8, sealing device 9, output be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com