High-conductivity nanometer heat conduction oil and preparation method thereof

A heat-conducting oil and nanotechnology, which is applied in the chemical industry, can solve the problem that the heat-conducting performance needs to be further improved, and achieve the effects of easy availability of production raw materials, high safety and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

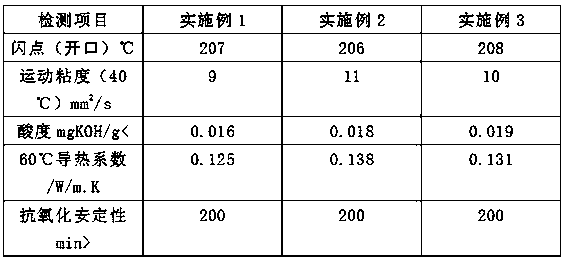

Examples

Embodiment 1

[0026] The preparation method of high-conductivity nano heat conduction oil is characterized in that it comprises the following steps:

[0027] (1) Put the carbon nanotubes into a muffle furnace and heat them to 420°C, treat them at high temperature for 2 hours, take them out and cool them to room temperature;

[0028] (2) cleaning the carbon nanotubes obtained in step (1) with dilute hydrochloric acid, distilled water and acetone, separating the carbon nanotubes from the cleaning solution by centrifugation after cleaning, and vacuum drying the separated carbon nanotubes;

[0029] (3) Take 1 part of carbon nanotubes obtained in step (2), and ultrasonically disperse them in 90 parts of base oil, and ultrasonically disperse them for 1 hour;

[0030] (4) Add 12 parts of polyetheramine and 2 parts of polymethacrylate to the oil sample treated in step (3), and continue stirring for 2 hours;

[0031] (5) Add 12 parts of hydroxybenzophenone, 3 parts of dialkylbenzenetriazole, 3 part...

Embodiment 2

[0033] The preparation method of high-conductivity nano heat conduction oil is characterized in that it comprises the following steps:

[0034] (1) Put the graphene into the muffle furnace and heat it to 400°C, treat it at high temperature for 3 hours, take it out and cool it to room temperature;

[0035] (2) washing the graphene obtained in step (1) with dilute hydrochloric acid, distilled water and acetone, and separating the graphene from the cleaning solution by centrifugal separation after cleaning, and vacuum drying the separated graphene;

[0036] (3) Take 0.5 parts of graphene obtained in step (2), ultrasonically disperse it in 85 parts of base oil, and ultrasonically 0.5 h;

[0037] (4) Add 15 parts of high molecular weight succinimide and 2 parts of alkyl acrylate polymer to the oil sample treated in step (3), and continue stirring for 3 hours;

[0038] (5) Add 15 parts of spiroethylene glycol, 4 parts of dialkylbenzenetriazole, 2 parts of thionyl octyl zinc salt, a...

Embodiment 3

[0040] The preparation method of high-conductivity nano heat conduction oil is characterized in that it comprises the following steps:

[0041] (1) Put carbon nanotubes and graphene into a muffle furnace and heat to 350°C, treat at high temperature for 4 hours, take it out and cool to room temperature;

[0042] (2) Clean the carbon nanotubes and graphene obtained in step (1) with dilute hydrochloric acid, distilled water and acetone. After cleaning, separate the carbon nanotubes and graphene from the cleaning solution by centrifugal separation. The separated carbon nanotubes and graphite Alkene is vacuum-dried;

[0043] (3) Take 0.5 parts of carbon nanotubes and 1 part of graphene obtained in step (2), ultrasonically disperse them in 100 parts of base oil, and ultrasonically disperse them for 1 hour;

[0044] (4) Add 10 parts of borated polyisobutylene succinimide and 1 part of ethylene-vinyl acetate copolymer to the oil sample treated in step (3), and continue stirring for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com