Environment-friendly bonding agent for leather and preparation method thereof

An adhesive and environmentally friendly technology, applied in polymer adhesive additives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the impact on the use of leather products and the health hazards of production personnel , insufficient waterproof and heat resistance, etc., to achieve the effects of excellent raw material compatibility, simple and convenient preparation, and excellent adhesion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

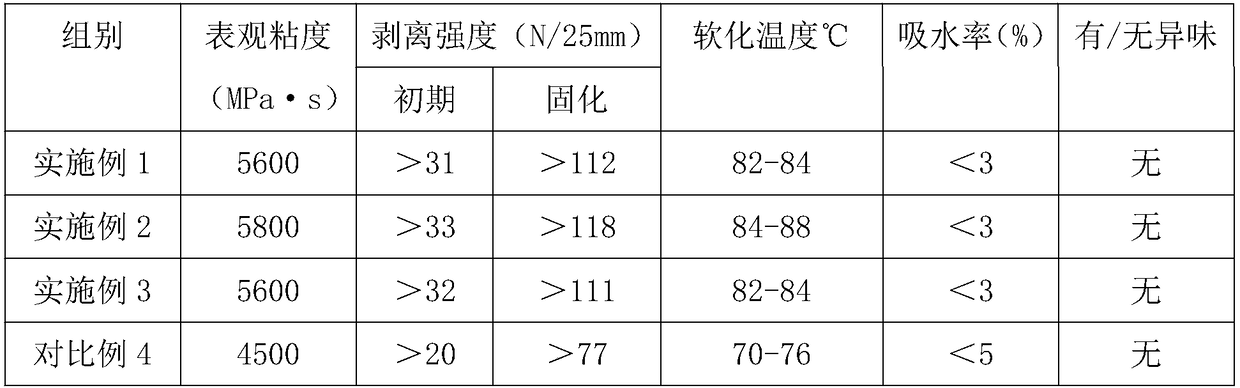

Examples

Embodiment 1

[0029] An environmentally friendly adhesive for leather, prepared by weighing the following raw materials: modified vinyl chloride-acrylate copolymer resin 40kg, phenolic resin 15kg, hide glue 4kg, polyethylene glycol 10kg, palm fiber 2kg, attapulgite clay 3kg , stearic acid 3kg, sodium tripolyphosphate 1kg, maleic anhydride modified polyethylene 0.8kg, ferrocene 0.4kg, dioctyl maleate 1kg, tert-butyl peroxy valerate 0.8kg, tert-butyl Alkylated aryl phosphate 0.8kg, aminosilane coupling agent KH-5501kg, antifreeze: formamide 1kg, antioxidant 10761kg and defoamer: polydimethylsiloxane 0.6kg;

[0030] The preparation process of modified vinyl chloride-acrylate copolymer resin is as follows:

[0031] Step 1: Weigh the following ingredients: 25kg of vinyl chloride, 15kg of methyl acrylate, 8kg of neopentyl glycol and 2kg of initiator;

[0032] Step 2: First add vinyl chloride, methyl acrylate, and neopentyl glycol into the reaction kettle and stir for 20 minutes at a stirring spe...

Embodiment 2

[0039]An environmentally friendly adhesive for leather, prepared by weighing the following raw materials: modified vinyl chloride-acrylate copolymer resin 45kg, phenolic resin 20kg, hide glue 6kg, polyethylene glycol 15kg, palm fiber 2.5kg, attapulgite clay 4kg, stearic acid 4kg, sodium tripolyphosphate 1.5kg, maleic anhydride modified polyethylene 1kg, ferrocene 0.6kg, dioctyl maleate 1.25kg, tert-butyl peroxy valerate 0.9kg, Tert-butylated aryl phosphate 0.9kg, aminosilane coupling agent KH-550 1.5kg, antifreeze agent: dimethyl sulfoxide 1.25kg, antioxidant 10102kg and defoamer: polydimethylsiloxane 0.7kg ;

[0040] The preparation process of modified vinyl chloride-acrylate copolymer resin is as follows:

[0041] Step 1: Weigh the following ingredients: vinyl chloride 28kg, methyl acrylate 18kg, neopentyl glycol 9kg and initiator 2.5kg;

[0042] Step 2: First add vinyl chloride, methyl acrylate, and neopentyl glycol into the reaction kettle and stir for 22 minutes at a st...

Embodiment 3

[0049] An environmentally friendly adhesive for leather, prepared by weighing the following raw materials: modified vinyl chloride-acrylate copolymer resin 50kg, phenolic resin 25kg, hide glue 8kg, polyethylene glycol 20kg, palm fiber 3kg, attapulgite clay 5kg , stearic acid 5kg, sodium tripolyphosphate 2kg, maleic anhydride modified polyethylene 1.2kg, ferrocene 0.8kg, dioctyl maleate 1.5kg, tert-butyl peroxy valerate 1kg, tert-butyl Kylated aryl phosphate 1kg, epoxy silane coupling agent KH-5602kg, antifreeze: dimethyl sulfoxide 1.5kg, antioxidant 10103kg and defoamer: polydimethylsiloxane 0.8kg;

[0050] The preparation process of modified vinyl chloride-acrylate copolymer resin is as follows:

[0051] Step 1: Weigh the following ingredients: 30kg of vinyl chloride, 20kg of methyl acrylate, 10kg of neopentyl glycol and 3kg of initiator;

[0052] Step 2: First add vinyl chloride, methyl acrylate, and neopentyl glycol into the reaction kettle and stir for 25 minutes at a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com