Iodine-doped graphene thin film with high thermal stability and method for preparing iodine-doped graphene thin film

A graphene film, high thermal stability technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as doping, and achieve the effect of reducing resistance, enhancing interaction force, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

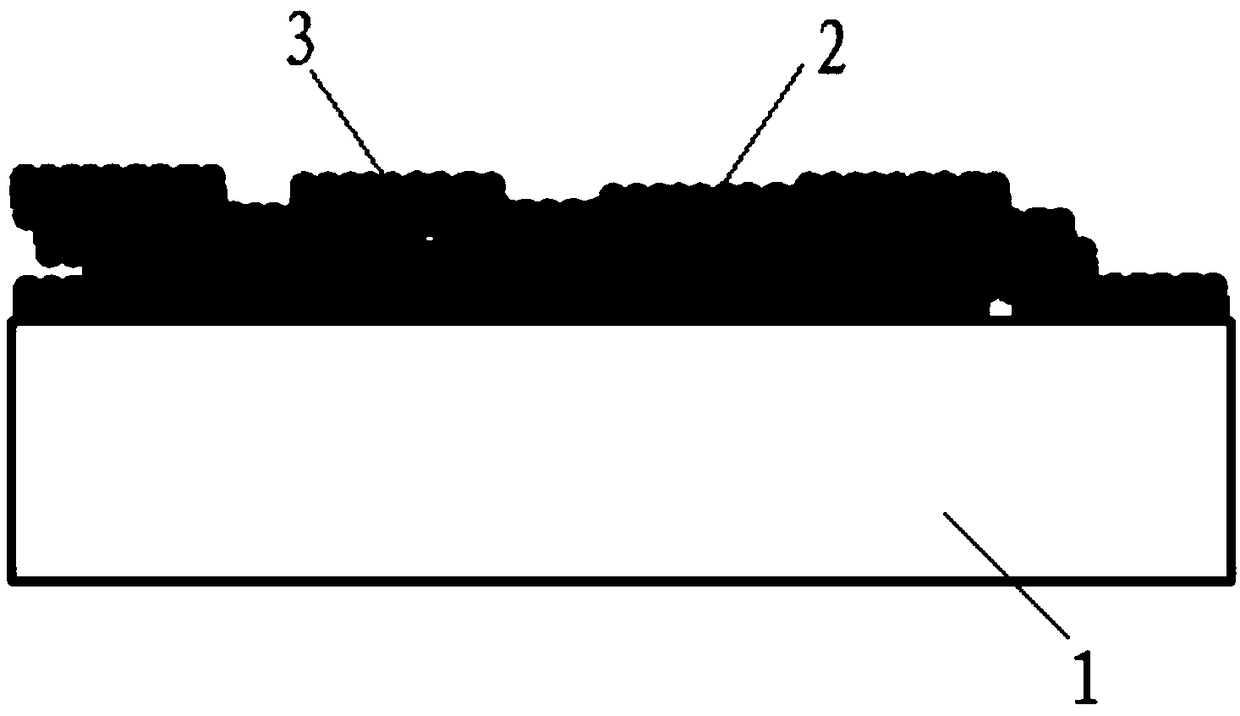

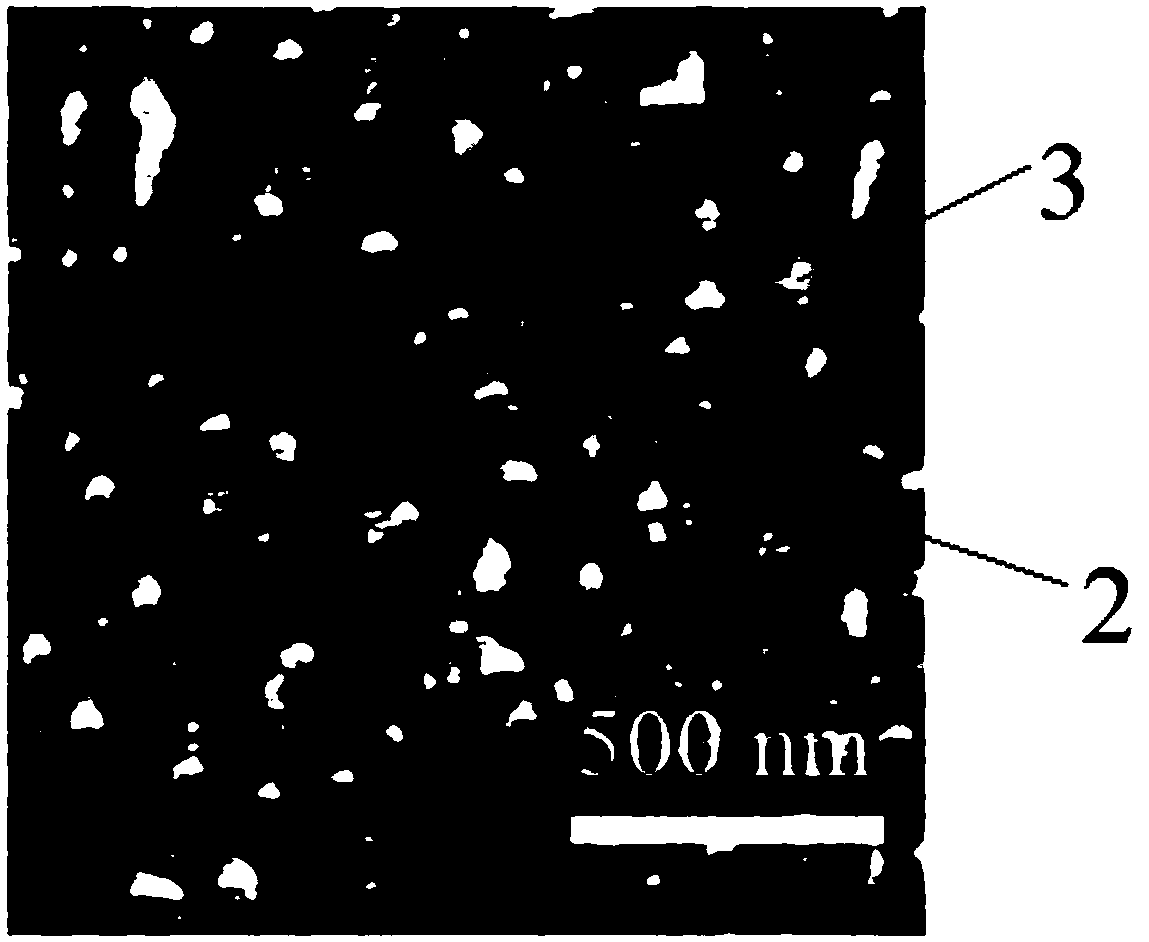

[0027] The highly thermally stable iodine-doped graphene film of this embodiment is composed of multilayer graphene microflakes doped with iodine dopant, and the multilayer graphene microflakes are randomly stacked along its plane direction, and the iodine dopant Exists in the form of atoms and ions.

[0028] The preparation method of the high thermal stability iodine-doped graphene film of the present embodiment comprises the following steps:

[0029] Step 1, cleaning and drying the glass in sequence;

[0030] Step 2: Add 50g of graphite powder into 1L of N-methylpyrrolidone, stir for 30min under the condition of 4000rpm and let it stand for 3h to obtain a suspension of graphene microflakes, the graphite in the suspension of graphene microflakes The number of layers of graphene microsheets is 2 to 4 layers. Add 10 g of ethyl cellulose to the suspension of graphene microsheets, then centrifuge to remove precipitated particles to obtain a supernatant, and add ethylene glycol t...

Embodiment 2

[0038] The highly thermally stable iodine-doped graphene film of this embodiment is composed of multilayer graphene microflakes doped with iodine dopant, and the multilayer graphene microflakes are randomly stacked along its plane direction, and the iodine dopant Exists in the form of atoms and ions.

[0039] The preparation method of the high thermal stability iodine-doped graphene film of the present embodiment comprises the following steps:

[0040] Step 1, cleaning and drying the glass in sequence;

[0041]Step 2: Add 50g of graphite powder into 1L of N-methylpyrrolidone, stir for 30min under the condition of 4000rpm and let it stand for 3h to obtain a suspension of graphene microflakes, the graphite in the suspension of graphene microflakes The number of layers of graphene microsheets is 2 to 4 layers. Add 10 g of ethyl cellulose to the suspension of graphene microsheets, then centrifuge to remove precipitated particles to obtain a supernatant, and add ethylene glycol to...

Embodiment 3

[0047] The highly thermally stable iodine-doped graphene film of this embodiment is composed of multilayer graphene microflakes doped with iodine dopant, and the multilayer graphene microflakes are randomly stacked along its plane direction, and the iodine dopant Exists in the form of atoms and ions.

[0048] The preparation method of the high thermal stability iodine-doped graphene film of the present embodiment comprises the following steps:

[0049] Step 1, cleaning and drying the glass in sequence;

[0050] Step 2: Add 50g of graphite powder into 1L of N-methylpyrrolidone, stir for 30min under the condition of 4000rpm and let it stand for 3h to obtain a suspension of graphene microflakes, the graphite in the suspension of graphene microflakes The number of layers of graphene microsheets is 2 to 4 layers. Add 10 g of ethyl cellulose to the suspension of graphene microsheets, then centrifuge to remove precipitated particles to obtain a supernatant, and add ethylene glycol t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com