Method for in-situ press-in to test and extract metal elastoplasticity parameters

A technology for extracting metal and elastoplasticity, applied in the direction of testing material hardness, etc., to achieve the effect of improving effectiveness and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment is the extraction of the elastic-plastic parameters of crystal copper. Including the following steps:

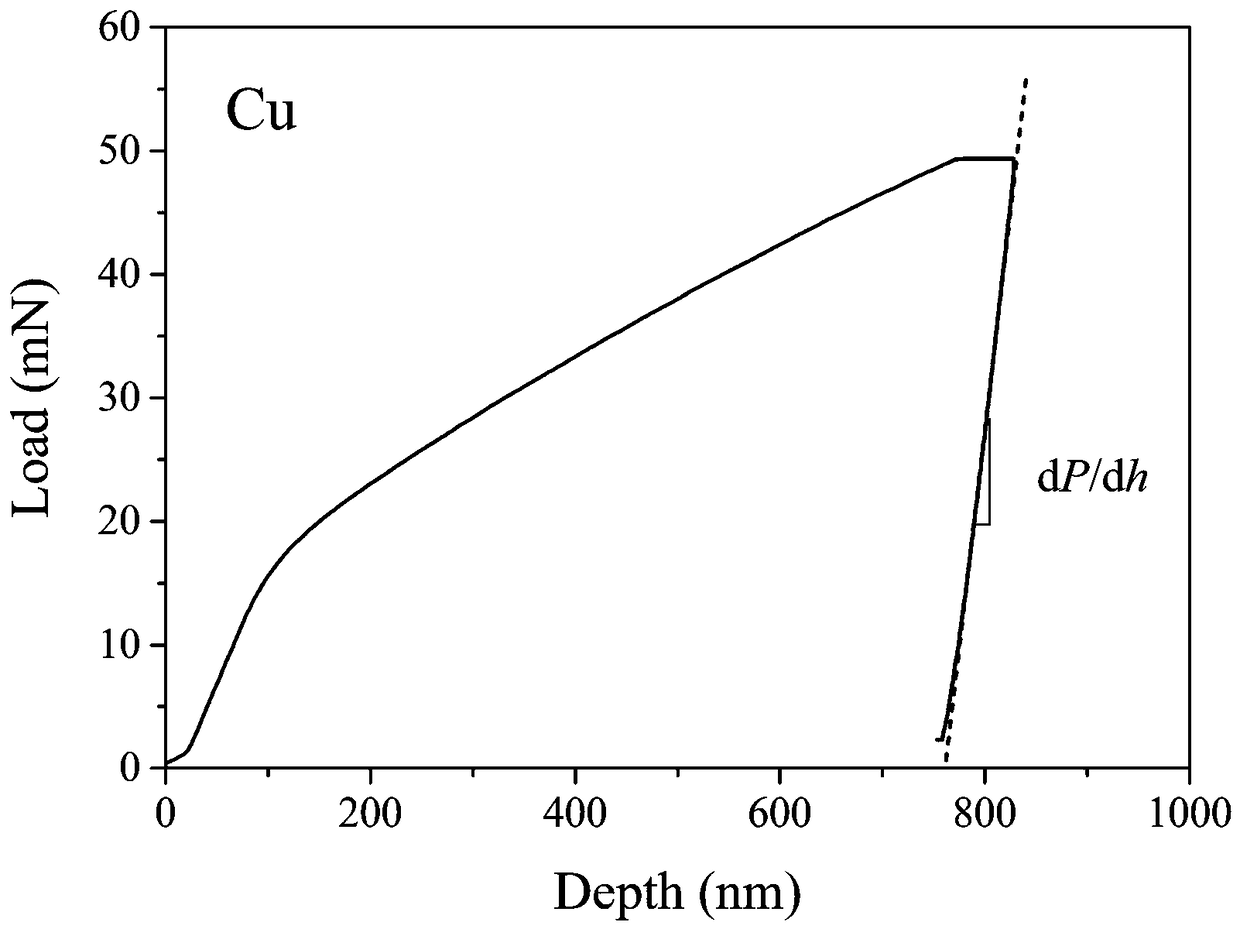

[0064] 1) A cylindrical diamond indenter with a diameter of 5.5 μm is used to carry out micro-indentation tests on crystal copper, and the unloading curve (such as figure 1 ) to get its reduced modulus E r It is: 129.5GPa, and the corresponding elastic modulus E is: 130.1GPa (copper Poisson's ratio v is set to 0.33);

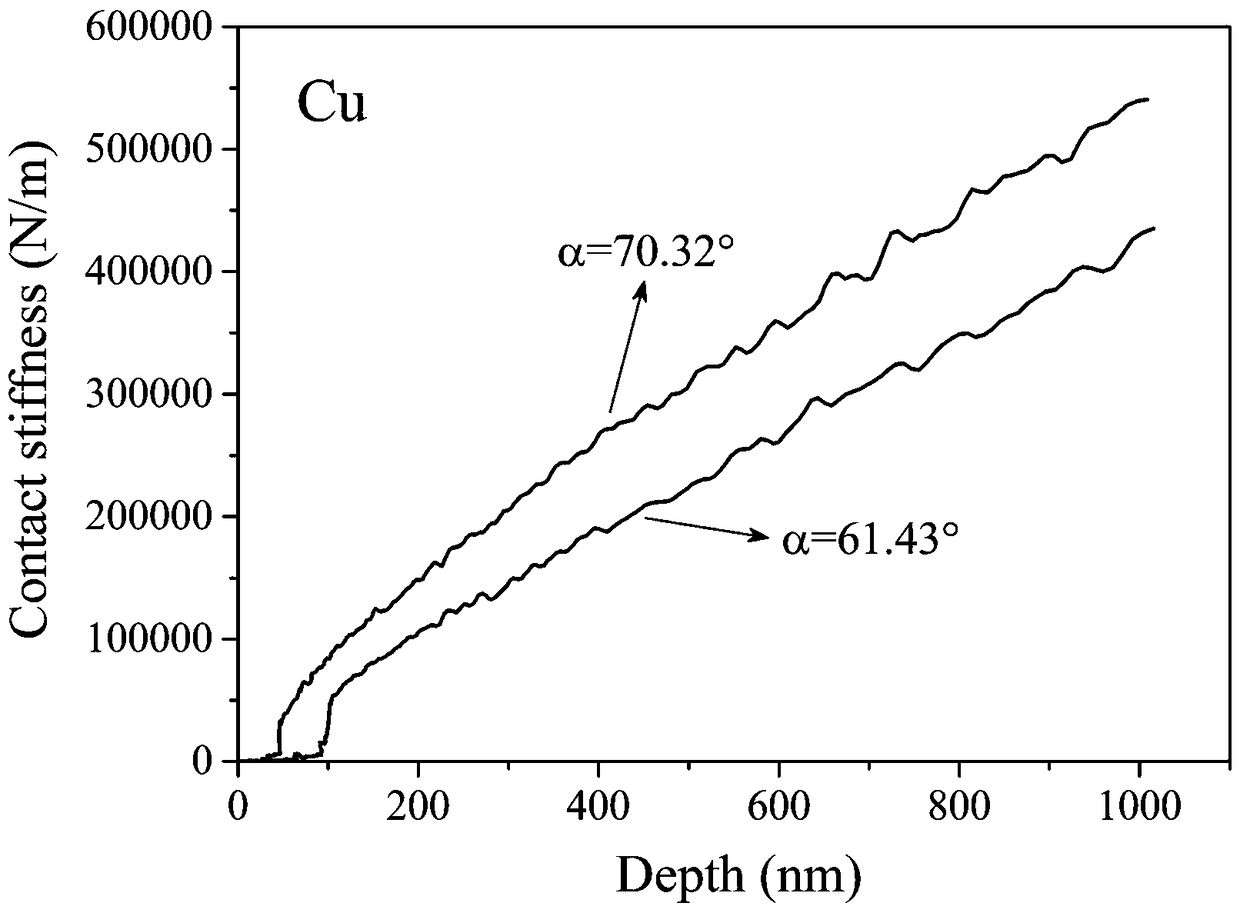

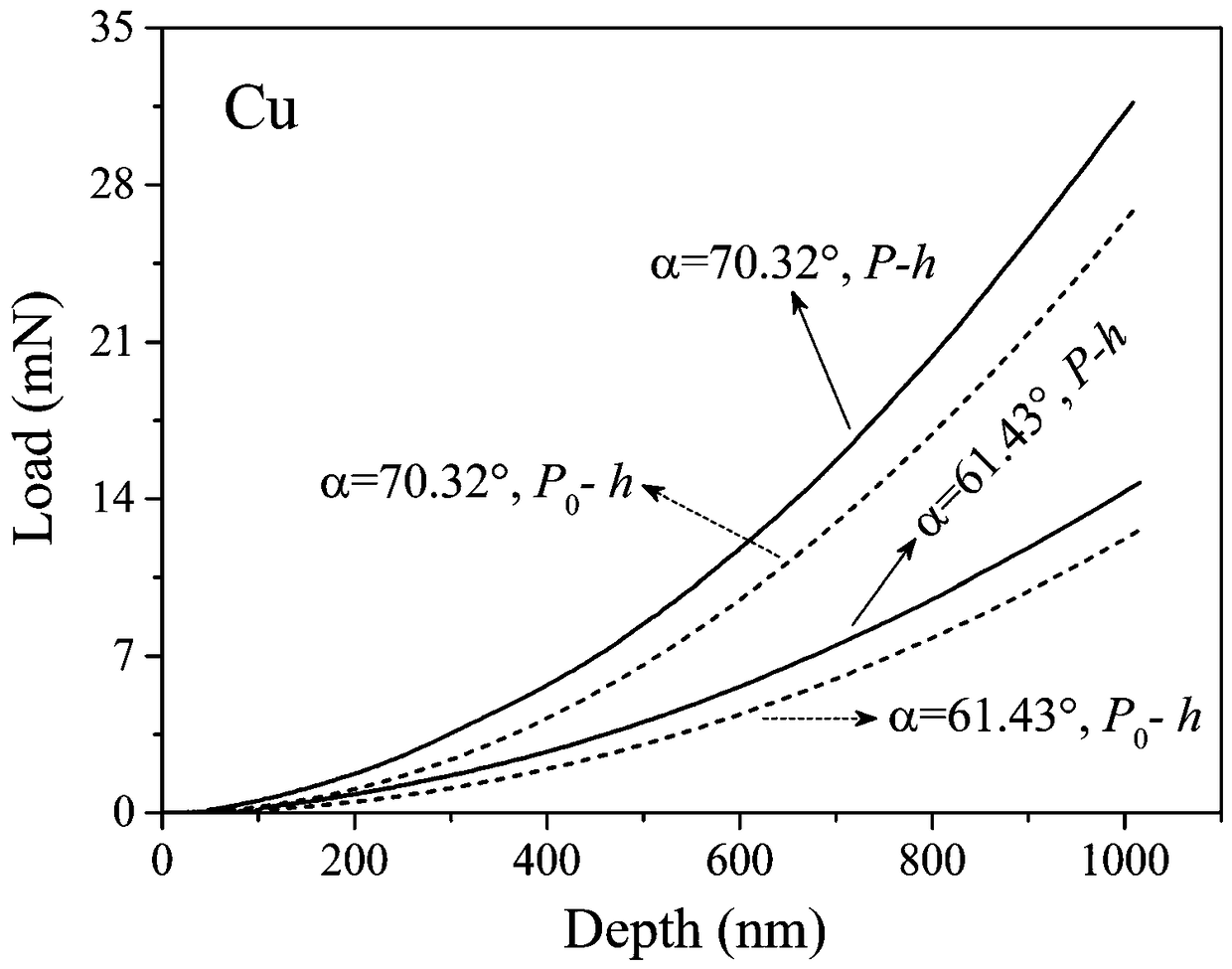

[0065] 2) Two kinds of triangular pyramidal diamond indenters with different cone angles (equivalent semi-cone angles are 61.43° and 70.32° respectively) were used to carry out indentation tests on metal copper combined with the continuous stiffness measurement method (CSM), and the indentation load was obtained as - Depth profile (P-h) and continuous measurement of contact stiffness (S-h), such as figure 2 ;

[0066] 3) Based on the relationship between contact area-stiffness-reduced modulus and hardness formula, the real contact a...

Embodiment 2

[0071] 1) A cylindrical diamond indenter with a diameter of 5.5 μm was used to perform micro-indentation tests on crystalline aluminum, and the unloading curve (such as Figure 5 ) to get its reduced modulus E r is 76.6GPa, and the corresponding elastic modulus E is 73.2GPa (the Poisson's ratio v of aluminum is set to 0.33);

[0072] 2) Two kinds of triangular pyramidal diamond indenters with different cone angles (equivalent semi-cone angles are 61.43° and 70.32° respectively) were used to carry out indentation tests on metal aluminum combined with the continuous stiffness measurement method (CSM), and the indentation load was obtained as - Depth profile (P-h) and continuous measurement of contact stiffness (S-h), such as Image 6 ;

[0073] 3) Based on the relational formula of contact area-stiffness-reduced modulus and hardness formula, the actual contact area between the indenter and aluminum and the change value of the hardness with the indentation depth during the inde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com