High-speed friction metal surface nano modified material and preparation method thereof

A nano-modified material and metal surface technology, applied in the field of high-speed friction metal surface nano-modified materials and their preparation, and the field of high-speed friction metal surface nano-modified materials, can solve the problem that the lubricating performance of lubricating oil cannot be improved immediately, and the optimization of lubricating oil is weak. , lubrication performance attenuation and other problems, to achieve the dual effect of improving lubrication and film repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

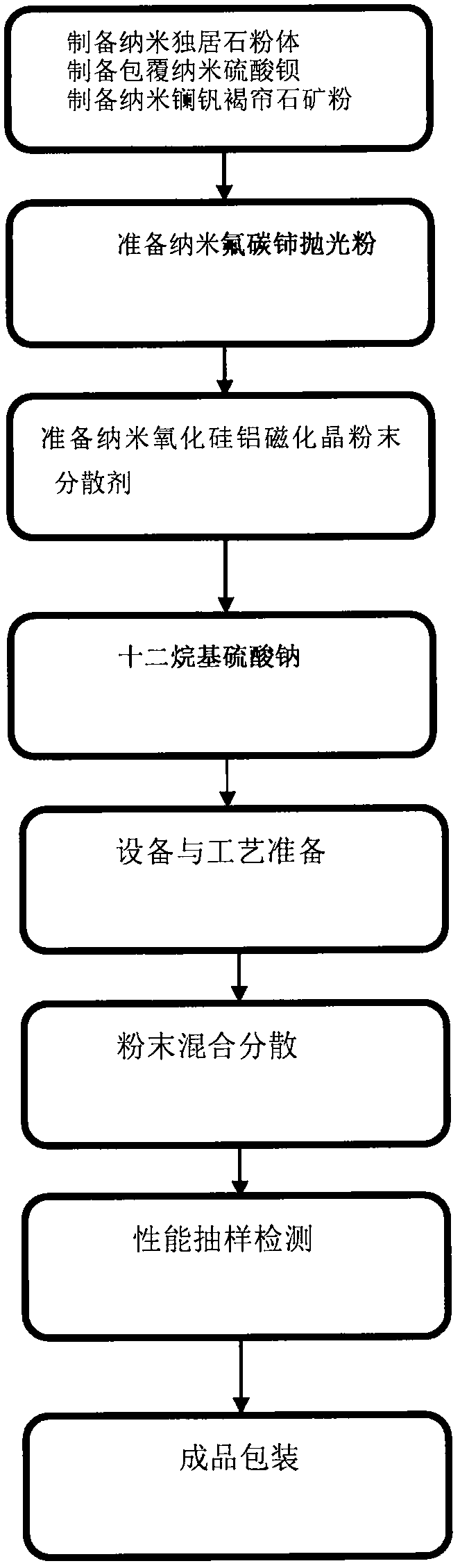

[0042] A kind of preparation method of high-speed friction metal surface nano-modified material, described preparation method comprises the following steps:

[0043] Step 1: Carry out flotation, magnetic separation, three-stage crushing of monazite ore, grind it into 5000-8000 mesh (1-3um), and then carry out ultrasonic crushing to form 100nm powder for later use;

[0044] Step 2: Use KH-550 silane coupling agent to organically coat the surface of nano-barium sulfate, add absolute ethanol, nano-barium sulfate and the corresponding proportion of silane coupling agent to the reaction kettle, feed N2, under N2 flow The temperature was raised to 85°C and the reaction was stirred for 6h. After the reaction, the product was vacuum-filtered while it was hot, and after ultrasonic dispersion (ultrasonic medium: water, absolute ethanol; time: 30min), centrifugal washing (medium: water, absolute ethanol; time: 25min), dried at 105°C 12h, stand-by after cooling.

[0045] Step 3: Purchas...

Embodiment 1

[0051] Step 1: Flotation and magnetic separation of 250 grams of monazite ore powder, three-stage crushing, grinding to 5000 mesh to 8000 mesh (1 to 3um), and ultrasonic crushing to 100nm powder for later use;

[0052] Step 2: Use KH-550 silane coupling agent to organically coat the surface of nano barium sulfate, add 100 grams of absolute ethanol, 100 grams of nano barium sulfate and 10 grams of silane coupling agent in the reaction kettle, feed N2, in N2 The temperature was raised to 85°C under airflow and the reaction was stirred for 6h. After the reaction, the product was vacuum-filtered while it was hot, dispersed by ultrasonic (ultrasonic medium: absolute ethanol; time: 30 min), centrifugal washing (medium: absolute ethanol; time: 25 min), dried at 105°C for 12 h, and cooled stand-by.

[0053] Step 3: Prepare 180 grams of nano-bastnasite polishing powder (Guangdong Dongna) with a particle size of 200nm to 500nm;

[0054] Step 4: Mix absolute ethanol with deionized wate...

Embodiment 2

[0063] Step 1: Flotation and magnetic separation of 180 grams of monazite ore powder, three-stage crushing, grinding into 5000-8000 mesh (1-3um), and then ultrasonic crushing into 100nm powder for later use;

[0064] Step 2: Use KH-550 silane coupling agent to organically coat the surface of nano-barium sulfate, add 100 grams of absolute ethanol, 80 grams of nano-barium sulfate and 10 grams of silane coupling agent in the reaction kettle, feed N2, in N2 The temperature was raised to 85°C under airflow and the reaction was stirred for 6h. After the reaction, the product was vacuum-filtered while it was hot, dispersed by ultrasonic (ultrasonic medium: absolute ethanol; time: 30 min), centrifugal washing (medium: absolute ethanol; time: 25 min), dried at 105°C for 12 h, and cooled stand-by.

[0065] Step 3: Prepare 150 grams of nano-bastnasite polishing powder (Guangdong Dongna) with a particle size of 200nm to 500nm;

[0066] Step 4: Mix absolute ethanol with deionized water (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com