High-toughness marble glue and preparation method thereof

A technology of marble glue and high toughness, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as low strength, poor wettability, and brittle colloids, and achieve toughness And the effect of strong stretchability, stable weather resistance and strong anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

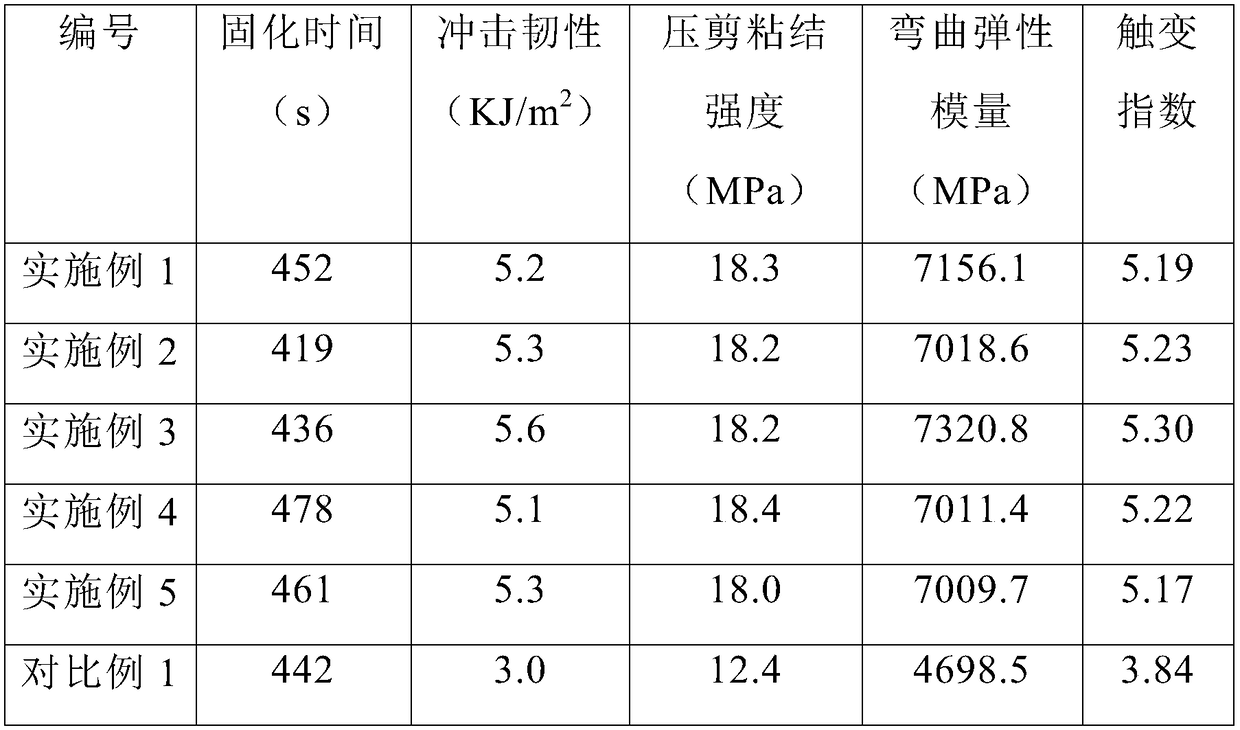

Examples

Embodiment 1

[0018] A high-toughness marble glue, comprising the following components in parts by weight: unsaturated polyester resin: 20 parts; polyether acrylate: 3 parts; nano core-shell rubber particles: 0.02 parts; trimethylolethane trimethylolethane Acrylate: 2.7 parts; Benzoyl peroxide: 0.3 parts; Fumed silica: 0.5 parts; Silica powder: 35 parts.

[0019] A preparation method of high-toughness marble glue, comprising the following steps: mixing unsaturated polyester resin, polyether acrylate, nano core-shell rubber particles, trimethylolethane triacrylate, fumed silica and silicon micropowder , fully mixed, stirred for 15 minutes, then added benzoyl peroxide, heated to 45°C, continued to stir evenly for 30 minutes, and then stood to cool to obtain high-toughness marble glue.

Embodiment 2

[0021] A high-toughness marble glue, comprising the following components in parts by weight: unsaturated polyester resin: 29 parts; polyether acrylate: 4.5 parts; nano-core-shell rubber particles: 0.01 parts; trimethylolethane trimethylolethane Acrylates: 4.5 parts; Lauroyl peroxide: 0.2 parts; Hydrogenated castor oil: 0.5 parts; Bentonite: 41 parts.

[0022] A preparation method of high-toughness marble glue, comprising the following steps: fully mixing unsaturated polyester resin, polyether acrylate, nano core-shell rubber particles, trimethylolethane triacrylate, hydrogenated castor oil and bentonite Mix and stir for 10 minutes, then add lauroyl peroxide, heat to 35°C, continue to stir evenly for 50 minutes, then let stand and cool to obtain high-toughness marble glue.

Embodiment 3

[0024] A high-toughness marble glue, comprising the following components by weight: unsaturated polyester resin: 26 parts; polyether acrylate: 5 parts; nano core-shell rubber particles: 0.03 parts; trimethylolethane trimethylolethane Acrylates: 3.3 parts; Benzoyl peroxide: 0.3 parts; Low molecular weight polyethylene: 1.5 parts; Barium sulfate: 47 parts.

[0025] A preparation method of high-toughness marble glue, comprising the following steps: mixing unsaturated polyester resin, polyether acrylate, nano core-shell rubber particles, trimethylolethane triacrylate, low molecular weight polyethylene and barium sulfate , fully mixed, stirred for 15 minutes, then added benzoyl peroxide, heated to 40°C, continued to stir evenly for 40 minutes, and then stood to cool to obtain high-toughness marble glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com