Garbage collection device with automatic shearing function

A recycling device and functional technology, which is applied in the field of garbage recycling devices with automatic cutting function, can solve the problems of medical staff inconvenience, virus infection, and reduce the safety of recycling garbage, so as to ensure the service life, improve safety and convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

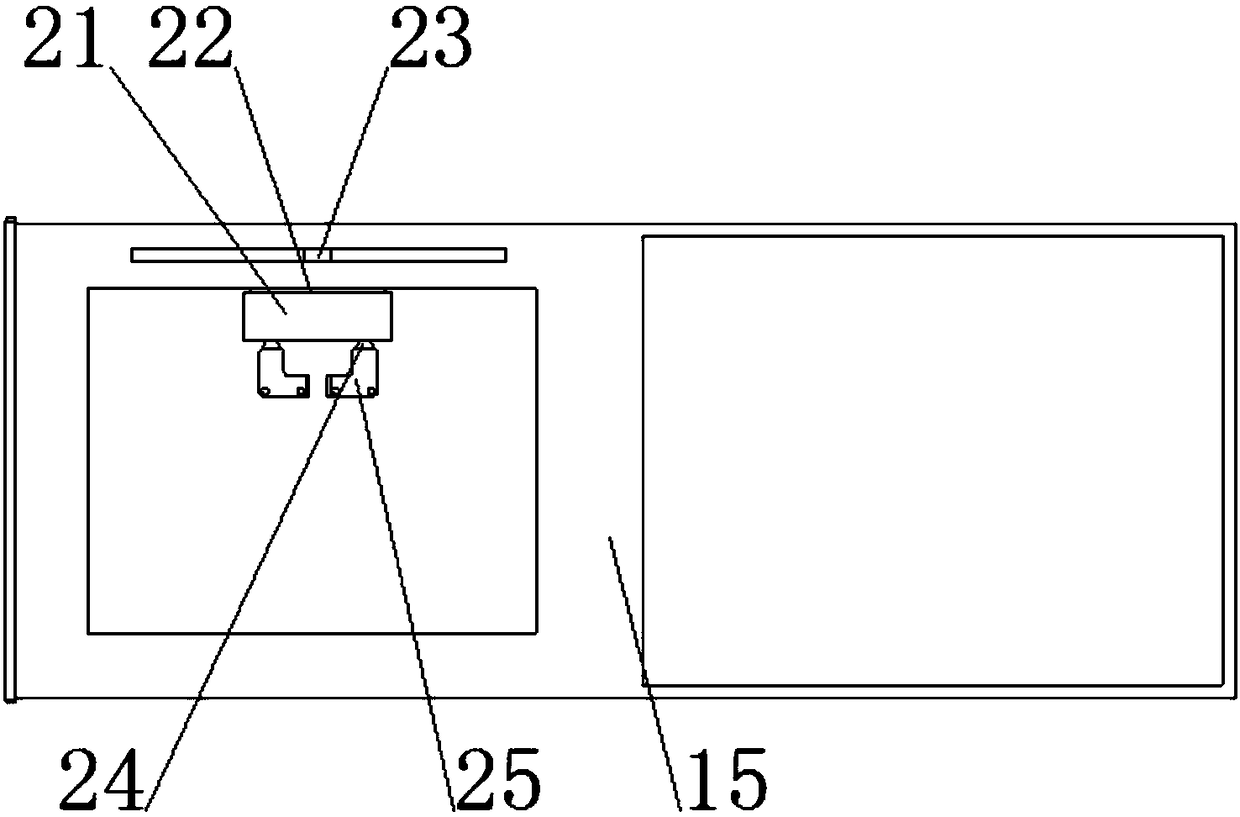

Image

Examples

Embodiment 1

[0041] The high-strength material is prepared by the following method: providing metal Mg, Gd, Y, Zn and Mn; according to the molecular formula (100-a-b-c-d)Mg-aGd-bY-cZn-dMn, weighing the metal Mg, Gd, Y, Zn and Mn; Crushing and ball milling the weighed metals Mg, Gd, Y, Zn and Mn to obtain a mixed powder; performing a first heat treatment on the mixed powder to obtain a reduced state mixed powder; vacuum melting the reduced state mixed powder to obtain an alloy ingot ; performing a first forging on the alloy ingot to obtain a first forged alloy ingot; performing a second heat treatment on the first forged alloy ingot to obtain a first heat treated alloy ingot. Wherein, a=10, b=4, c=1, d=0.5. The method for preparing a high-strength material further includes: performing a second forging on the first heat-treated alloy ingot to obtain a second forged alloy ingot; performing a third heat treatment on the second forged alloy ingot to obtain a second heat-treated alloy ingot. Th...

Embodiment 2

[0043] The high-strength material is prepared by the following method: providing metal Mg, Gd, Y, Zn and Mn; according to the molecular formula (100-a-b-c-d)Mg-aGd-bY-cZn-dMn, weighing the metal Mg, Gd, Y, Zn and Mn; Crushing and ball milling the weighed metals Mg, Gd, Y, Zn and Mn to obtain a mixed powder; performing a first heat treatment on the mixed powder to obtain a reduced state mixed powder; vacuum melting the reduced state mixed powder to obtain an alloy ingot ; performing a first forging on the alloy ingot to obtain a first forged alloy ingot; performing a second heat treatment on the first forged alloy ingot to obtain a first heat treated alloy ingot. Among them, a=12, b=5, c=2, d=0.8. The method for preparing a high-strength material further includes: performing a second forging on the first heat-treated alloy ingot to obtain a second forged alloy ingot; performing a third heat treatment on the second forged alloy ingot to obtain a second heat-treated alloy ingot. ...

Embodiment 3

[0045] The high-strength material is prepared by the following method: providing metal Mg, Gd, Y, Zn and Mn; according to the molecular formula (100-a-b-c-d)Mg-aGd-bY-cZn-dMn, weighing the metal Mg, Gd, Y, Zn and Mn; Crushing and ball milling the weighed metals Mg, Gd, Y, Zn and Mn to obtain a mixed powder; performing a first heat treatment on the mixed powder to obtain a reduced state mixed powder; vacuum melting the reduced state mixed powder to obtain an alloy ingot ; performing a first forging on the alloy ingot to obtain a first forged alloy ingot; performing a second heat treatment on the first forged alloy ingot to obtain a first heat treated alloy ingot. Among them, a=11, b=4.5, c=1.5, d=0.6. The method for preparing a high-strength material further includes: performing a second forging on the first heat-treated alloy ingot to obtain a second forged alloy ingot; performing a third heat treatment on the second forged alloy ingot to obtain a second heat-treated alloy ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com