Welding automatic clamp used for stirring friction welding and control method thereof

A friction stir welding and automatic technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor work efficiency, low degree of automation, high labor cost, etc., to achieve improved versatility, high degree of automation, and reduced labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

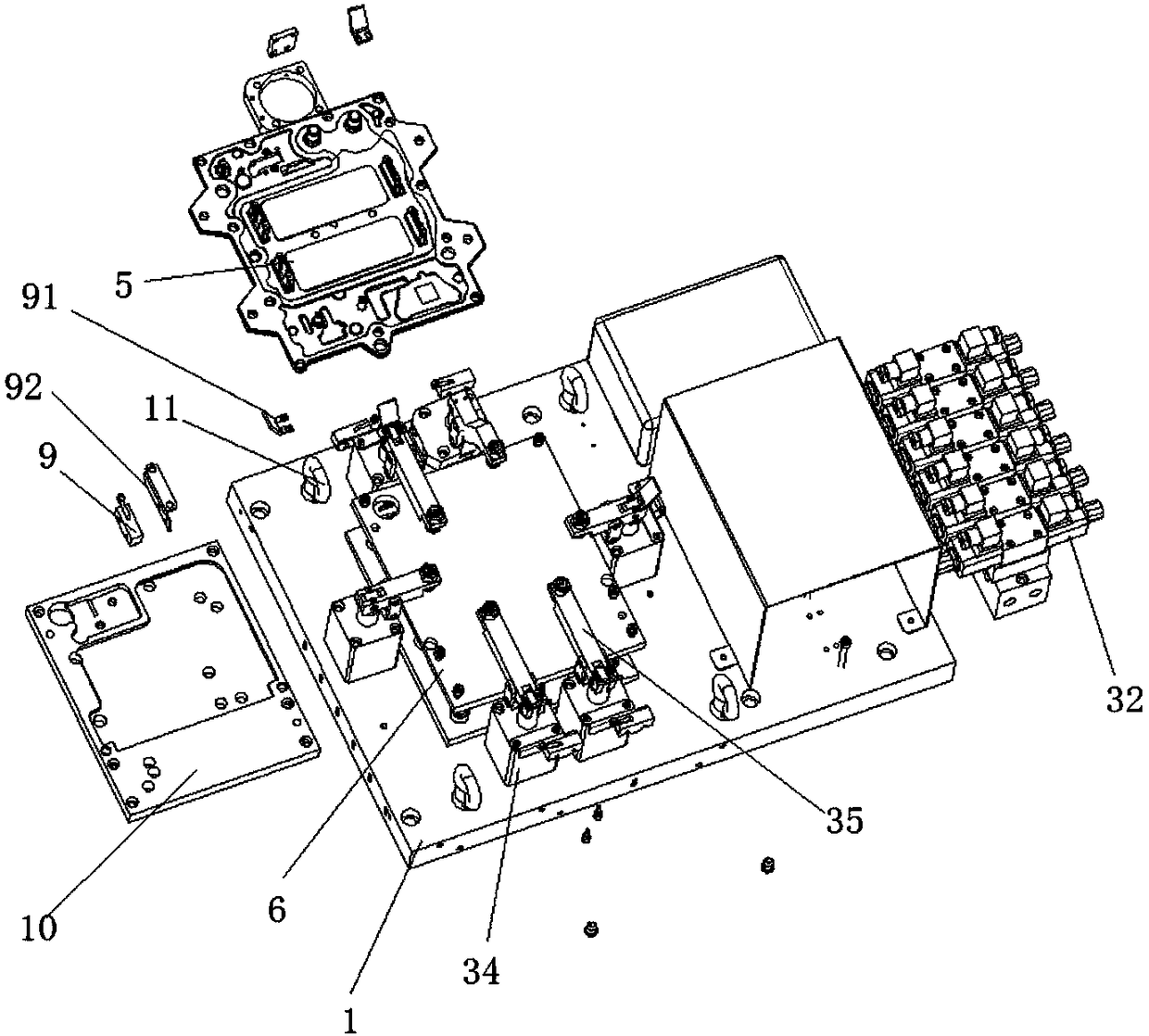

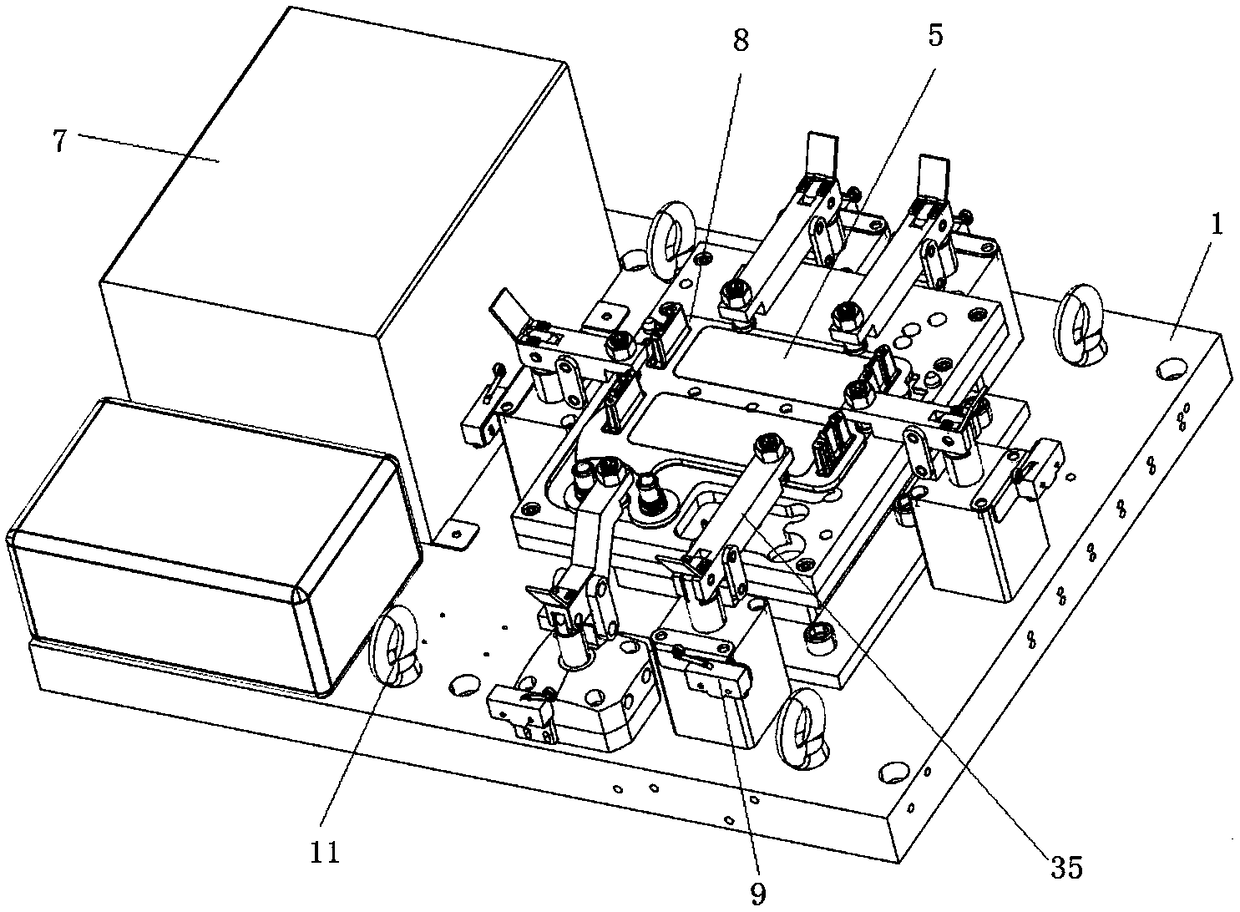

[0041] see Figure 1 to Figure 5 As shown, it is an exploded view of the welding automatic fixture used for friction stir welding of the present invention, a structural schematic diagram of the hydraulic mechanism, a perspective view, a perspective view of the hydraulic cylinder and a perspective view of the bracket.

[0042] combine figure 1 with figure 2 As shown, a welding automatic fixture for friction stir welding includes a base plate 1, a controller 2, a hydraulic mechanism 3, a detection device 4 and a bracket 6 for placing workpieces 5 to be welded. The holes are used to fix the bracket 6 on the bottom plate 1 by screws, and the hydraulic mechanism 3 and the detection device 4 are both connected to the controller 2 .

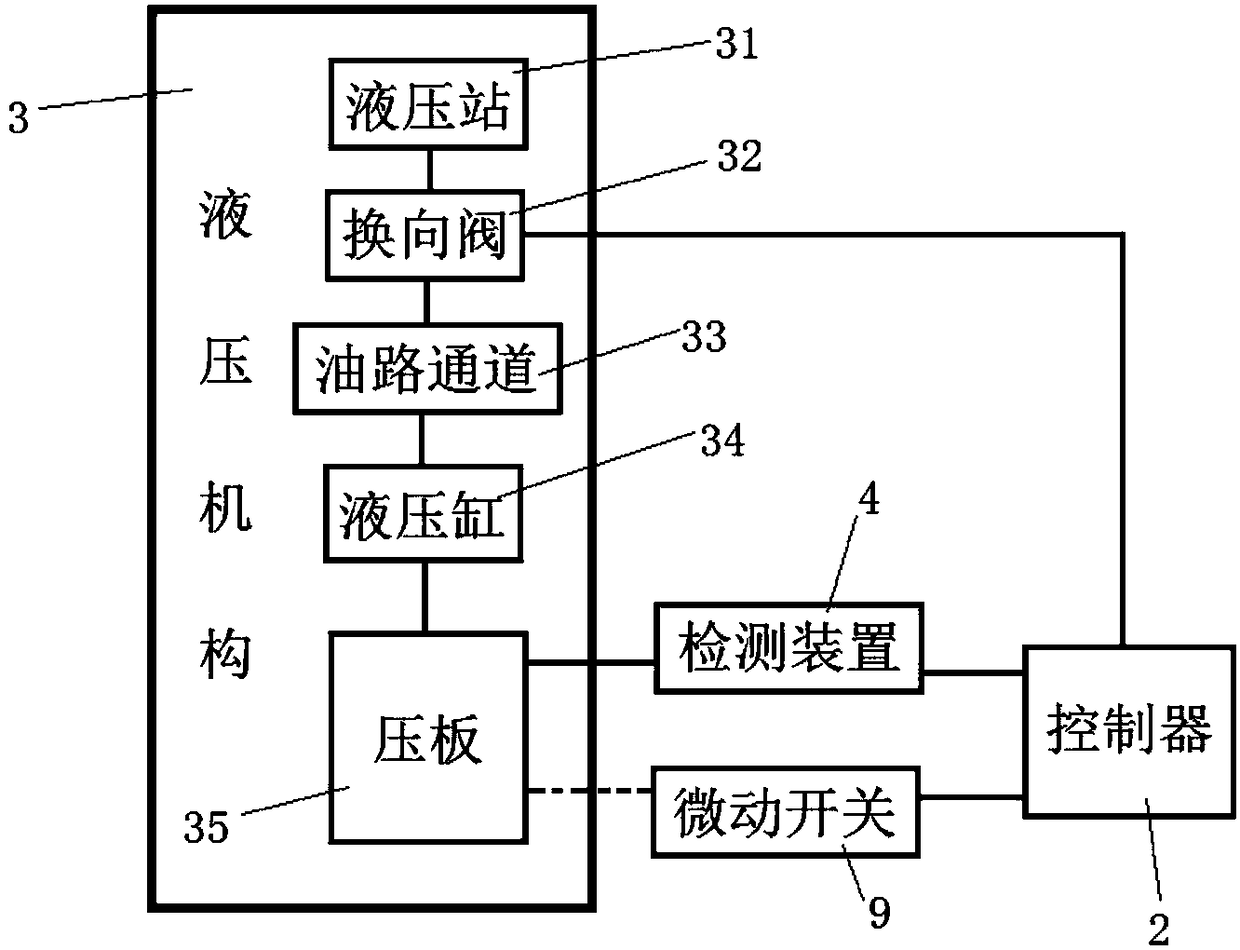

[0043] Such as figure 2 As shown, the hydraulic mechanism 3 includes a hydraulic station 31, a reversing valve 32, an oil channel 33, and a hydraulic cylinder 34 connected in sequence, and the hydraulic cylinder 34 is provided with a pressing plate...

Embodiment 2

[0059] The difference between the above-mentioned automatic welding fixture for friction stir welding in this embodiment is that the reversing valve 32 is connected to the hydraulic cylinder 34 in a one-to-one correspondence, and the hydraulic cylinder 34 is connected to the reversing valve 32 Connected by the oil channel 33, iron filings or powder will be produced on the surface of the workpiece when the workpiece is processed. If the oil channel 33 is arranged on the outer surface, iron filings or powder are likely to accumulate on the oil channel, and it is difficult to clean. In this embodiment, the oil channel 33 is arranged in the base plate 1, and the material of the base plate 1 is generally a stainless steel plate. The wiring design of the oil channel 33 is carried out inside the base plate 1 through a special process, so that the hydraulic cylinder 34 and Oil supply can work normally between reversing valve 32.

[0060] In this example, if Figure 6 to Figure 11 sho...

Embodiment 3

[0063] As described above, a welding automatic fixture for friction stir welding, the difference between this embodiment and the first embodiment is that, as Figure 4 As shown, the hydraulic cylinder 34 is provided with a micro switch 9, and the pressing plate 35 is provided with a micro switch pressing block 91, and the position of the micro switch 9 is adapted to the position of the micro switch pressing block 91, When the pressing plate 35 releases the workpiece and is in a lifted state, the microswitch pressing block 91 touches the switch of the microswitch 9 . The micro switch 9 is fixed on the hydraulic cylinder 34 through a micro switch bracket 92 provided on the hydraulic cylinder 34 .

[0064] The micro switch 9 is a contact mechanism with a small contact interval and a snap action mechanism, which performs switching action with a predetermined stroke and a predetermined force. It is covered with a shell, and an operating reed is provided outside it. When the micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com