Preparation of soybean molasses biological cellulose moisture mask

A technology of biological cellulose and soybean molasses, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as no reports, and achieve the effects of reducing cost, prolonging action time, and being difficult to evapotranspiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

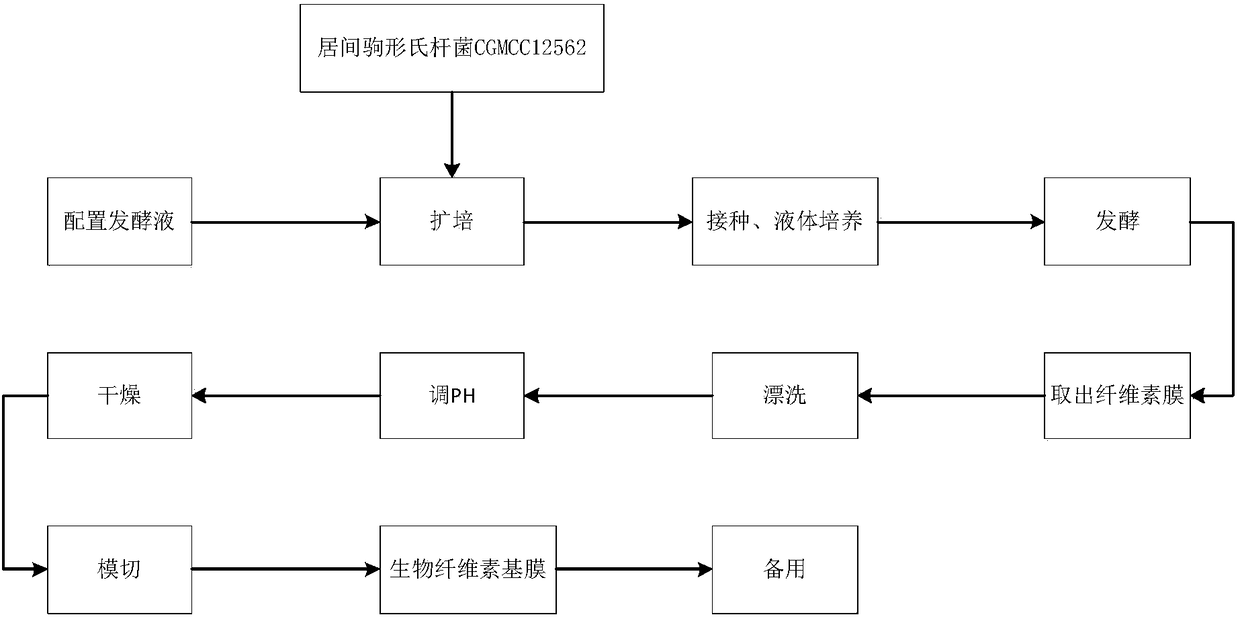

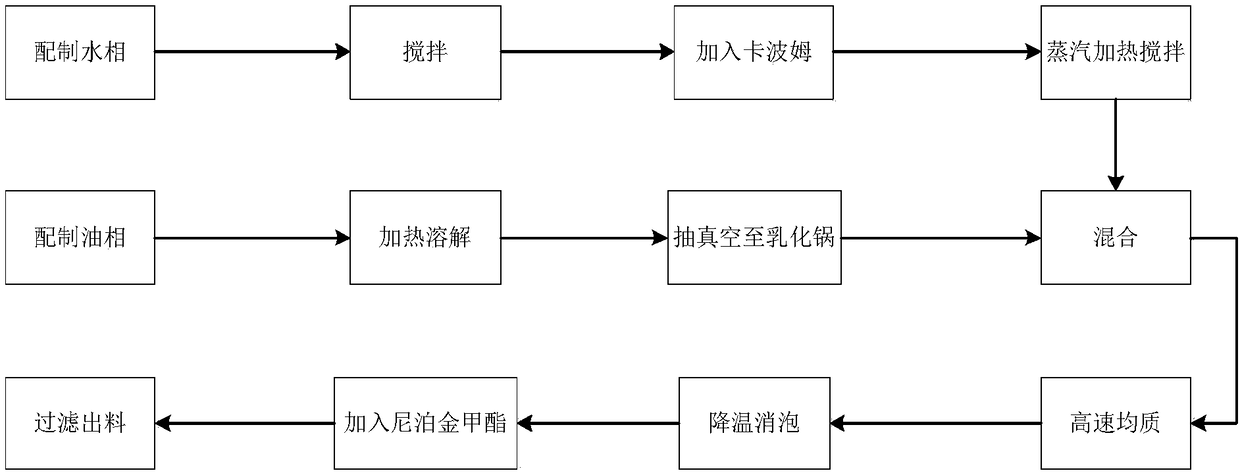

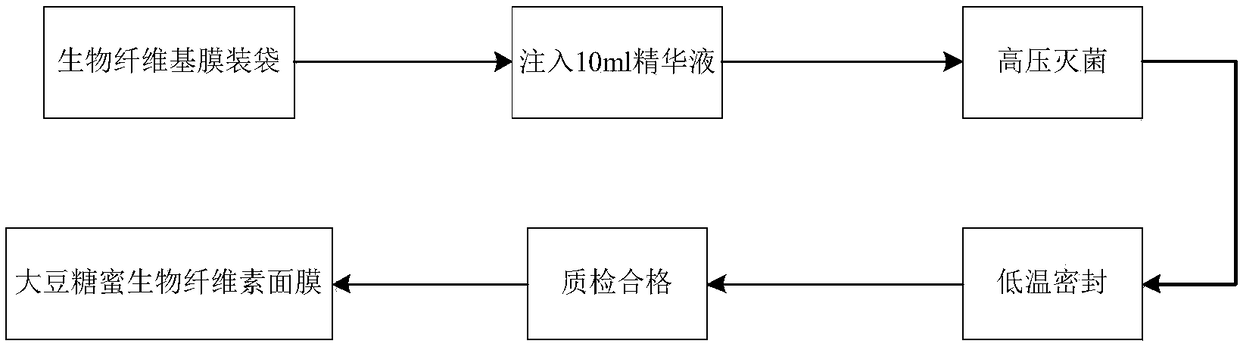

[0043] A kind of preparation of embodiment 1 soybean molasses biological cellulose moisturizing facial mask, its steps are:

[0044] (1) Preparation of soybean molasses biocellulose base film

[0045] 1) Preparation of medium

[0046] Seed medium: 2% glucose, 0.5% yeast extract powder, 0.5% peptone, 0.27% disodium hydrogen phosphate, 0.115% citric acid, make up the rest with water, adjust pH=6;

[0047] Molasses medium: soybean molasses solid content 15Brix, corn gluten powder 0.15%, zinc sulfate 0.15%, malic acid 0.4%, adjust PH=6;

[0048] The culture medium was sterilized by high pressure steam, irradiated with ultraviolet light and cooled to room temperature;

[0049] 2) Inoculation static culture

[0050] Komagataeibacter intermedius CGMCC12562 (Komagataeibacter intermedius CGMCC12562) were inoculated in the seed medium for expansion, cultured in a shaker incubator (30°C, 160r) for 22h, and then inoculated in molasses medium, when the bacterial cellulose membrane Take i...

Embodiment 2

[0068] The preparation of embodiment 2 a kind of soybean molasses biological cellulose moisturizing mask, its steps are:

[0069] (1) Preparation of soybean molasses biocellulose base film

[0070] 1) Preparation of medium

[0071] Seed medium: 2% glucose, 0.5% yeast extract powder, 0.5% peptone, 0.27% disodium hydrogen phosphate, 0.115% citric acid, make up the rest with water, adjust pH=6;

[0072] Molasses medium: soybean molasses solid content 15Brix, corn gluten powder 0.15%, zinc sulfate 0.15%, malic acid 0.4%, adjust PH=6;

[0073] The culture medium was sterilized by high pressure steam, irradiated with ultraviolet light and cooled to room temperature;

[0074] 2) Inoculation static culture

[0075] Komagataeibacter intermedius CGMCC12562 (Komagataeibacter intermedius CGMCC12562) were inoculated in the seed medium for expansion, cultured in a shaker incubator (30°C, 160r) for 22h, and then inoculated in molasses medium, when the bacterial cellulose membrane Take it...

Embodiment 3

[0093] Embodiment 3 A kind of preparation of soybean molasses biological cellulose moisturizing mask, its steps are:

[0094] (1) Preparation of soybean molasses biocellulose base film

[0095] 1) Preparation of medium

[0096] Seed medium: 2% glucose, 0.5% yeast extract powder, 0.5% peptone, 0.27% disodium hydrogen phosphate, 0.115% citric acid, make up the rest with water, adjust pH=6;

[0097] Molasses medium: soybean molasses solid content 15Brix, corn gluten powder 0.15%, zinc sulfate 0.15%, malic acid 0.4%, adjust PH=6;

[0098] The culture medium was sterilized by high pressure steam, irradiated with ultraviolet light and cooled to room temperature;

[0099] 2) Inoculation static culture

[0100] Komagataeibacter intermedius CGMCC12562 (Komagataeibacter intermedius CGMCC12562) were inoculated in the seed medium for expansion, cultured in a shaker incubator (30°C, 160r) for 22h, and then inoculated in molasses medium, when the bacterial cellulose membrane Take it out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com