High-performance and high-barrier-property food packaging film and preparation method thereof

A high-barrier, high-performance technology, applied in the direction of packaging, wrapping paper, flexible coverings, etc., can solve the problem that barrier performance and tensile strength cannot be coordinated, barrier properties cannot achieve good synergy, film stretching The strength has not been improved and other problems, and the effect of improving the moisture permeability of the film, excellent mechanical properties, and improving the barrier property of the film is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

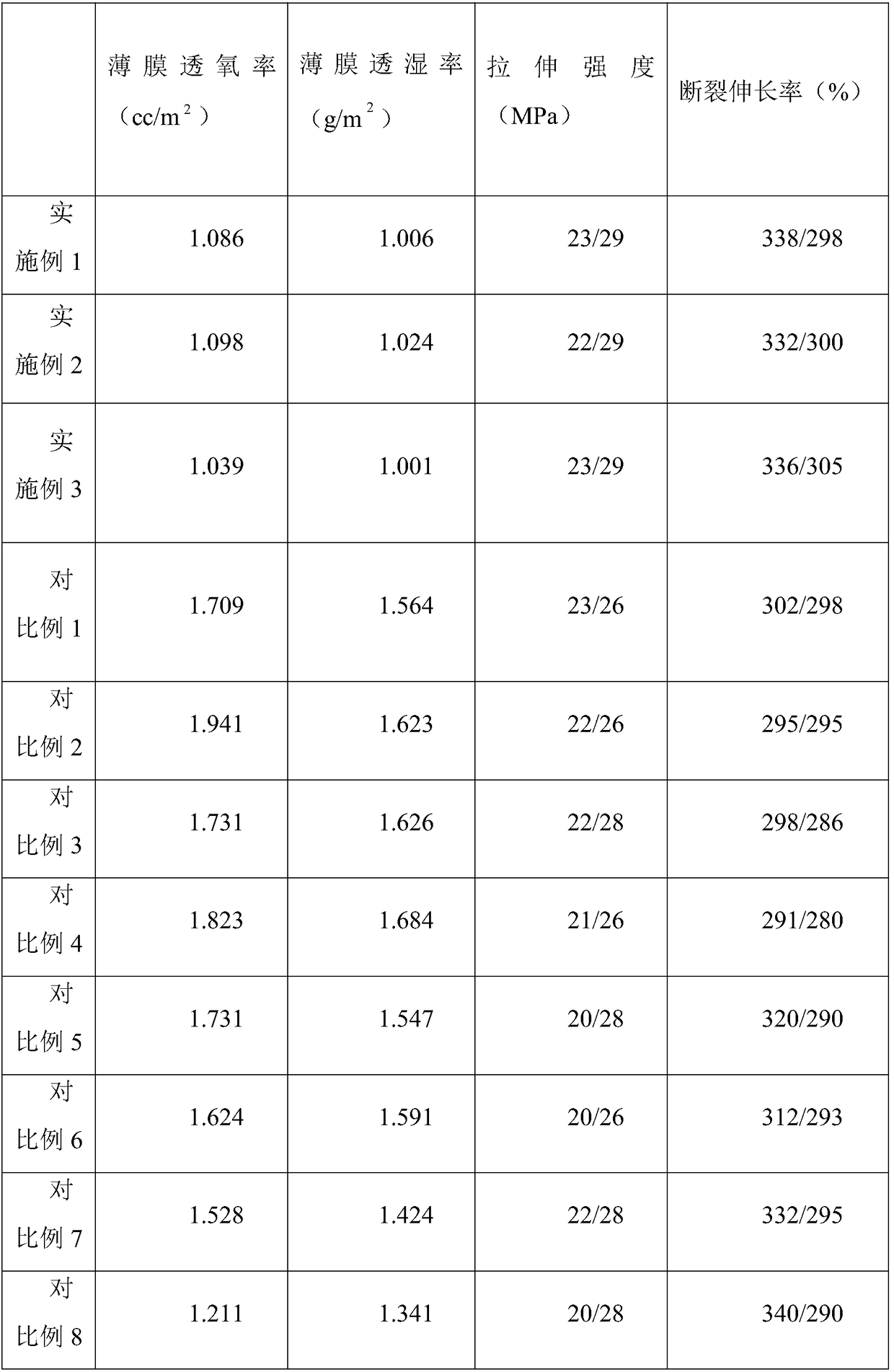

Examples

Embodiment 1

[0024] A kind of high-performance high-barrier food packaging film of the present embodiment comprises the following raw materials in parts by weight:

[0025] 38 parts of modified polymethylethylene carbonate, 22 parts of nano silicon dioxide, 12 parts of ethylene-vinyl acetate copolymer, 3 parts of emulsifier, 2 parts of processing aid, 14 parts of water.

[0026] The preparation method of the modified polymethylethylene carbonate of this example is to add rosin and 1,4-butanediol into the reaction kettle, the reaction temperature is 75°C, and the reaction time is 35min, and then polymethylethylene carbonate is added to it. Ethylene carbonate, heat up to 85-95°C, continue to react for 45 minutes, stir at 1450r / min for 20 minutes, then add carboxybutyl cyanide latex, calcium stearate silane coupling agent KH-560, and continue to stir for 45 minutes. Finally, dry at 40°C for 18 hours to obtain modified polymethylethylene carbonate.

[0027] The emulsifier in this embodiment i...

Embodiment 2

[0036] A kind of high-performance high-barrier food packaging film of the present embodiment comprises the following raw materials in parts by weight:

[0037] 44 parts of modified polymethylethylene carbonate, 24 parts of nano silicon dioxide, 16 parts of ethylene-vinyl acetate copolymer, 5 parts of emulsifier, 4 parts of processing aid, 20 parts of water.

[0038]The preparation method of the modified polymethylethylene carbonate of this example is to add rosin and 1,4-butanediol into the reaction kettle, the reaction temperature is 85°C, and the reaction time is 45min, and then polymethylethylene carbonate is added to it. For ethylene carbonate, heat up to 85-95°C, continue to react for 55 minutes, stir at 1550r / min for 40 minutes, then add carboxybutyl cyanide latex, calcium stearate silane coupling agent KH-560, and continue to stir for 55 minutes. Finally, dry at 50°C for 22 hours to obtain modified polymethylethylene carbonate.

[0039] The emulsifier in this embodimen...

Embodiment 3

[0048] A kind of high-performance high-barrier food packaging film of the present embodiment comprises the following raw materials in parts by weight:

[0049] 41 parts of modified polymethylethylene carbonate, 23 parts of nano silicon dioxide, 14 parts of ethylene-vinyl acetate copolymer, 4 parts of emulsifier, 3 parts of processing aid, 16 parts of water.

[0050] The preparation method of the modified polymethylethylene carbonate of this example is to add rosin and 1,4-butanediol into the reaction kettle, the reaction temperature is 80°C, and the reaction time is 40min, and then polymethylethylene carbonate is added to it. Ethylene carbonate, heat up to 90°C, continue to react for 50min, stir at 1500r / min for 30min, then add carboxybutyl cyanide latex, calcium stearate silane coupling agent KH-560, continue to stir for 50min, and finally Dry at 50°C for 20 hours to obtain modified polymethylethylene carbonate.

[0051] The emulsifier in this embodiment is a mixture of Twee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com