A kind of attapulgite supported cerium doped mntio x Ternary component low-temperature denitrification catalyst and preparation method thereof

An attapulgite and low-temperature denitrification technology, applied in the field of flue gas denitrification, can solve the problems of difficult fixation of active components, complicated process preparation, small specific surface area, etc., achieve good mechanical and thermal stability, simple preparation process, and improved reaction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

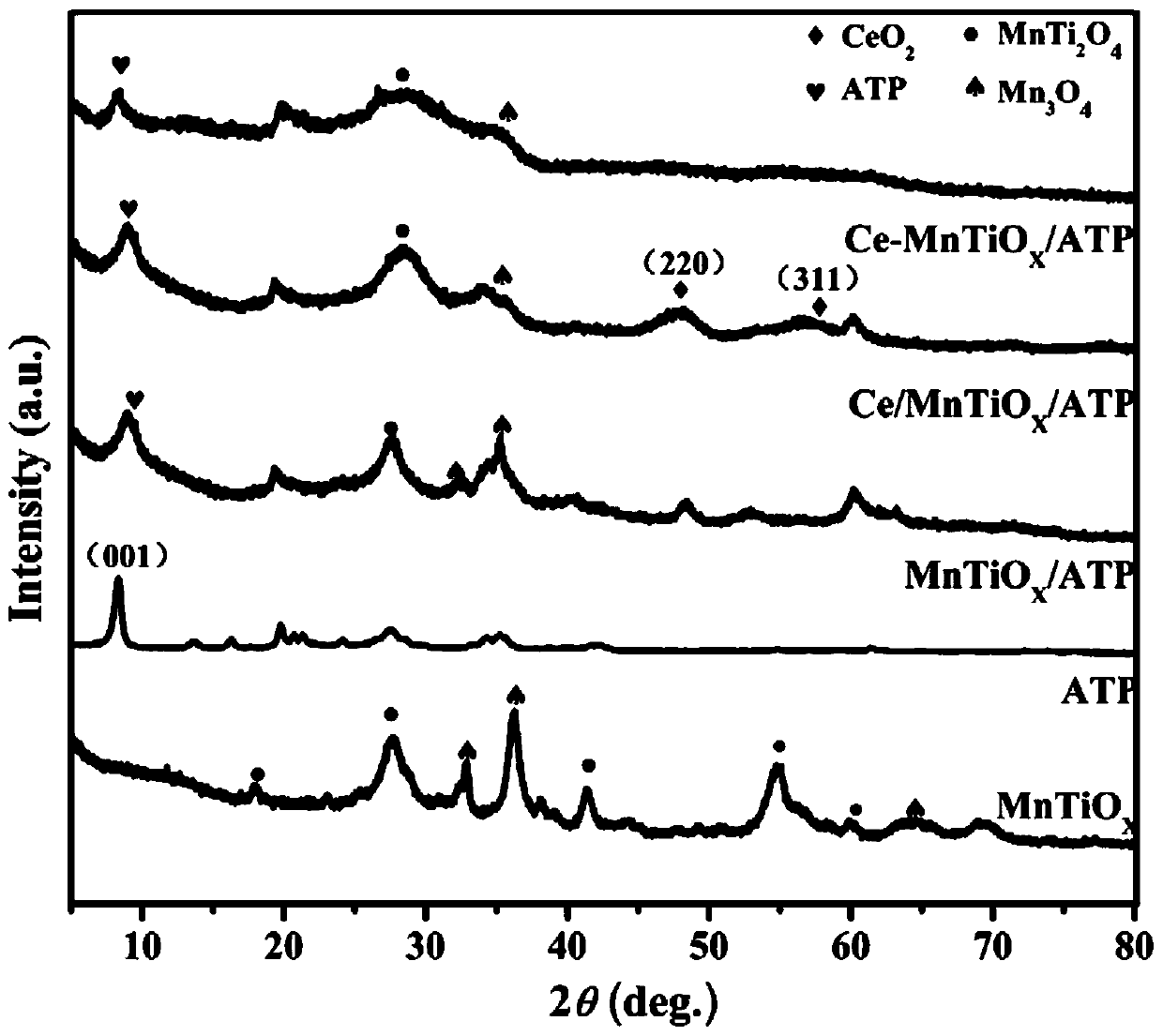

Image

Examples

Embodiment 1

[0029] (1) Dissolve 5 g of raw soil attapulgite in 300 mL of HCl solution with a concentration of 1 mol / L, stir and react at a speed of 300 r / min for 4 h, the purpose is to remove impurities, and at the same time move hydroxyl groups on the surface of attapulgite. After the reaction, filter with suction, wash and dry. as a carrier.

[0030] (2) Put 3.0g CTAB (cetyltrimethylammonium bromide) into a 500ml three-necked flask, and dissolve it in deionized water to obtain a solution with a concentration of about 1g / 100mL, and place it in a constant temperature water bath at 30°C Stir until dissolved, and turn off the constant temperature water bath.

[0031] (3) Grind and sieve the acidified attapulgite prepared in step (1) and weigh 5g, disperse it in 30ml deionized water and add it into step (2) while stirring to prepare a 1.5g / ml mixed dispersion, take 3.75 Add 5g of titanium sulfate and 5.6g of 50% manganese nitrate into a three-necked flask and stir for 0.5h.

[0032] (4) 2...

Embodiment 2

[0036] (1) Dissolve 5 g of original soil attapulgite in 300 mL of HCl solution with a concentration of 1 mol / L, and stir for 4 hours at a speed of 300 r / min. After the reaction, filter with suction, wash and dry. as a carrier.

[0037] (2) Put 3.0g CTAB (cetyltrimethylammonium bromide) into a 500ml three-necked flask, and dissolve it in deionized water to obtain a solution with a concentration of about 1g / 100mL, and place it in a constant temperature water bath at 30°C Stir until dissolved, and turn off the constant temperature water bath.

[0038] (3) Grind and sieve the acidified attapulgite prepared in step (1) and weigh 5g, disperse it in 30ml deionized water and add it into step (2) while stirring to prepare a 1.5g / ml mixed dispersion, take 2.25 g titanium sulfate and 3.36 g 50% manganese nitrate were added to a three-necked flask and stirred for 0.5 h.

[0039] (4) 2g Ce(NO 3 ) 3 ·6H 2 O was further added into the three-necked flask in (2), stirred for about 20 min...

Embodiment 3

[0042] (1) Dissolve 5 g of original soil attapulgite in 300 mL of HCl solution with a concentration of 1 mol / L, and stir for 4 hours at a speed of 300 r / min. After the reaction, filter with suction, wash and dry. as a carrier.

[0043] (2) Put 3.0g CTAB (cetyltrimethylammonium bromide) into a 500ml three-necked flask, and dissolve it in deionized water to obtain a solution with a concentration of about 1g / 100mL, and place it in a constant temperature water bath at 30°C Stir until dissolved, and turn off the constant temperature water bath.

[0044] (3) Grind and sieve the acidified attapulgite prepared in step (1) and weigh 5g, disperse it in 30ml deionized water and add it into step (2) while stirring to prepare a 1.5g / ml mixed dispersion, take 4.5 Add 1 g of titanium sulfate and 11.2 g of 50% manganese nitrate into a three-necked flask and stir for 0.5 h.

[0045] (4) 2g Ce(NO 3 ) 3 ·6H 2 O was further added into the three-necked flask in (2), stirred for about 20 min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com