Multifunctional cellulose film and preparation method thereof

A cellulose film and multi-functional technology, applied in the field of multi-functional cellulose film and its preparation, can solve the problems of complex experimental process, limited application range, and single performance, and achieve the effects of low energy consumption, simple synthesis, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

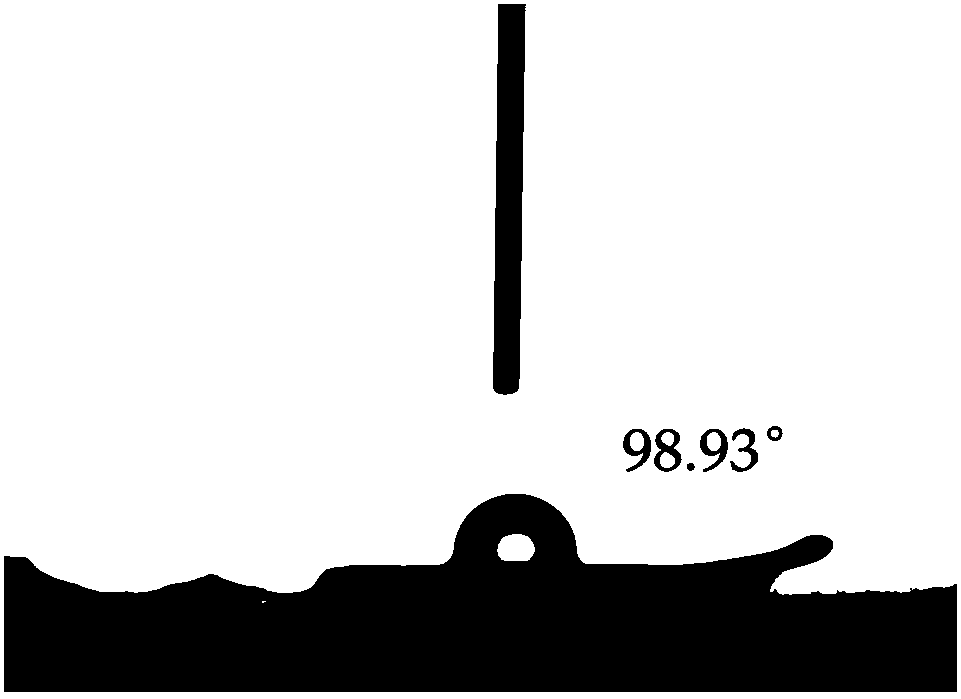

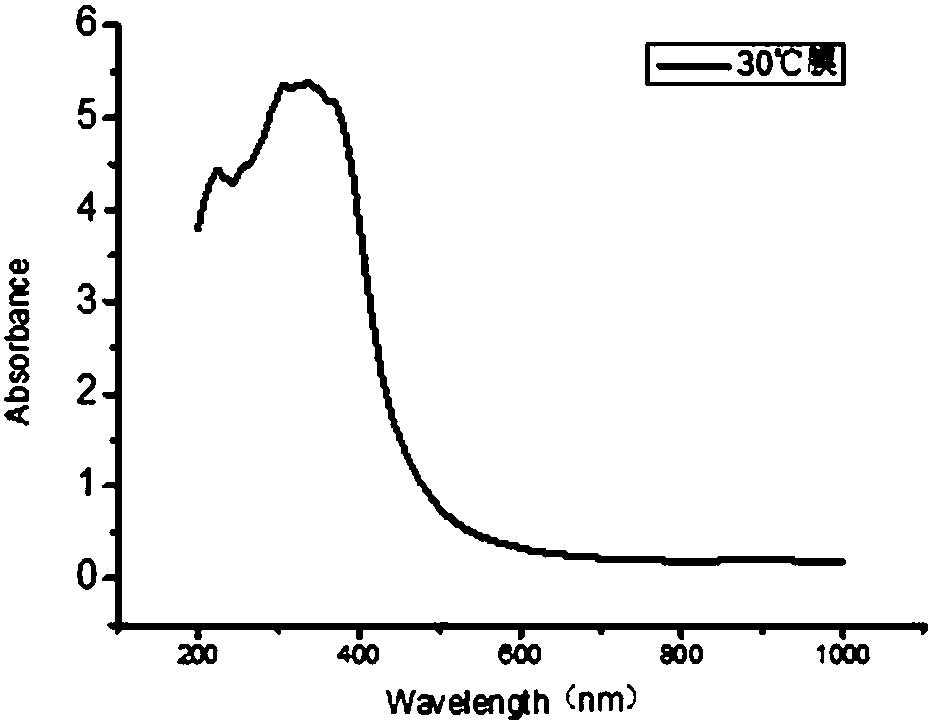

[0026] (1) 2g of pulp cellulose is added to 50ml of a mixed solution containing 7wt% NaOH and 12wt% urea, after mixing evenly, the pulp cellulose suspension is obtained, and 2g of sodium periodate is added to the pulp cellulose under stirring In the suspension, use 2M hydrochloric acid solution to adjust the pH to 4, and oxidize at 50°C for 1 hour to obtain an oxidized pulp cellulose suspension; add 1 g of polyethyleneimine to the above pulp cellulose suspension for 3 hours of grafting reaction, Obtain a pulp cellulose suspension solution; the obtained pulp cellulose suspension solution is centrifuged at 10,000rpm for 10min, and the lower sediment is separated to obtain the lower sediment; the lower sediment is washed 4 times and filtered to obtain a relatively dry solid mixture, using a flat vulcanizer The solid mixture was heat-cured and pressed at 30° C. and 10 MPa for 10 minutes to obtain a multifunctional cellulose film.

[0027] (2) On the prepared multifunctional cellul...

Embodiment 2

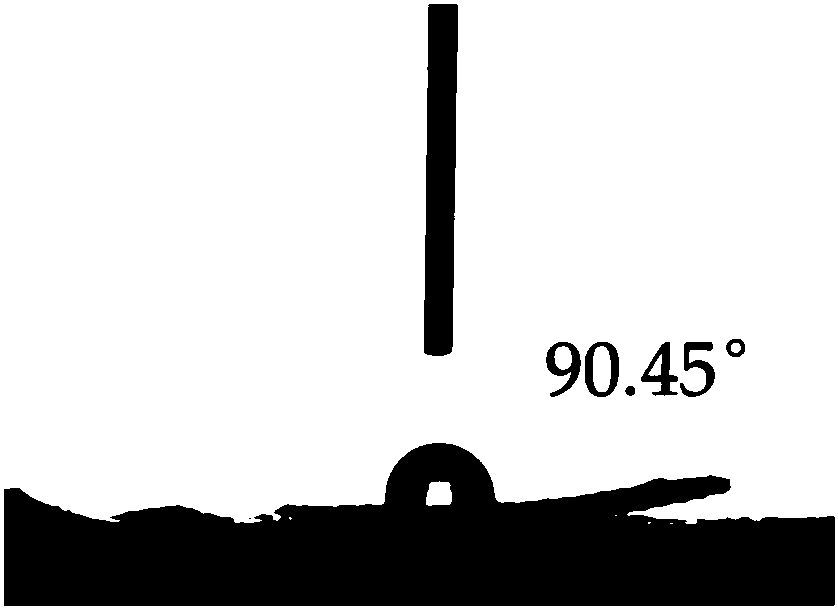

[0033] (1)) 2g cotton cellulose is added to 50ml containing 7wt% NaOH and in the mixed solution that contains 12wt% urea, after mixing evenly, cotton cellulose suspension is obtained, 2g sodium periodate is added this cellulose under agitation In the suspension, use 2M hydrochloric acid solution to adjust the pH to 4, and oxidize at 50°C for 2 hours to obtain an oxidized cotton cellulose suspension; add 1 g of polyethyleneimine to the above cotton cellulose suspension to carry out grafting reaction for 3 hours, Obtain cotton cellulose suspension solution; Gained cotton cellulose suspension solution is centrifuged 10min under the condition of 10000rpm, separates and obtains lower layer sediment; Gained lower layer sediment obtains comparatively dry solid mixture after 4 times of suction filtration, and this solid mixture Heat curing and pressing at 90° C. and 10 MPa for 10 minutes to obtain a multifunctional cotton cellulose film.

[0034] (2) Cut a 2cm*1cm rectangular strip on...

Embodiment 3

[0040](1)) 2g cotton cellulose is added to 50ml containing 7wt% NaOH and in the mixed solution that contains 12wt% urea, after mixing evenly, cotton cellulose suspension is obtained, 2g sodium periodate is added this cellulose under agitation In the suspension, use 2M hydrochloric acid solution to adjust the pH to 4, and oxidize at 50°C for 2 hours to obtain an oxidized cotton cellulose suspension; add 1 g of polyethyleneimine to the above cotton cellulose suspension to carry out grafting reaction for 3 hours, Obtain cotton cellulose suspension solution; Gained cotton cellulose suspension solution is centrifuged 10min under the condition of 10000rpm, separates and obtains lower layer sediment; Gained lower layer sediment obtains comparatively dry solid mixture after 4 times of suction filtration, and this solid mixture Heat curing and pressing at 150° C. and 10 MPa for 10 minutes to obtain a multifunctional cotton cellulose film.

[0041] (2) Cut a 2cm*1cm rectangular strip on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com