Method for preparing zeolitized particle material by using coal gangue powder generation dust residue

A technology for granular materials and coal gangue, which is applied in the field of solid waste resource utilization and water treatment materials, can solve problems such as being unsuitable for industrial application, unable to reasonably solve the problems of effective resource utilization of gangue power generation ash and slag, and complicated methods, and achieving easy Pulverizing, weakening the clogging of the filter material layer, and good filtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

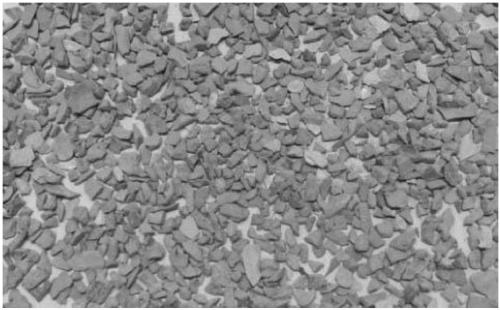

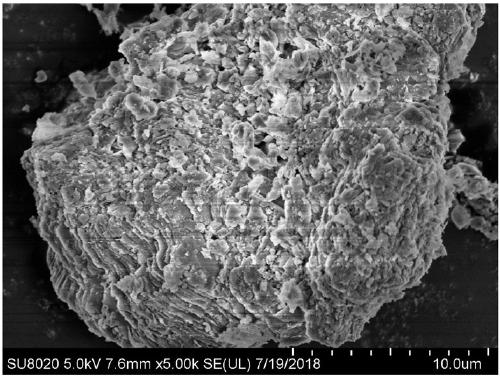

[0023] (1) Process the coal gangue power generation ash in the drum type tank mill for 1 hour, carry out selective crushing and screening, and obtain five particle sizes of figure 1 , figure 2 shown.

[0024] (2) preparing mass concentration is 15% sodium hydroxide solution.

[0025] (3) According to <0.5, 0.5~1, 1~3, 3-5, 5-8mm, the solid-liquid ratio of particles and sodium hydroxide solution is 1g:3mL, 1g:2mL, 1g:1mL respectively , 1g:1mL, 1g:1mL, the particles of different particle sizes and sodium hydroxide solution were added to the reactor.

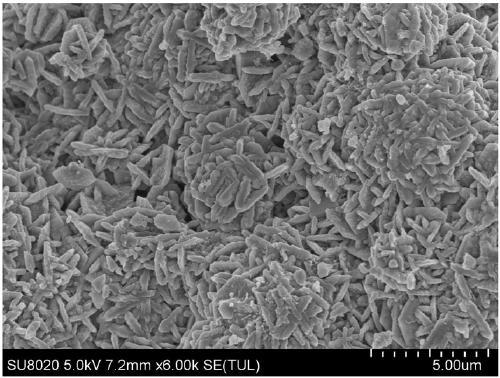

[0026] (4) Heat the material in the reactor to 90°C, and keep it warm for several hours (the corresponding reaction time for the five particle sizes of <0.5, 0.5~1, 1~3, 3-5, 5-8mm is 8h respectively , 12h, 24h, 24h, 24h), during the reaction process, the pump is used to extract the solution from the bottom of the reactor and transport it to the top of the reactor, so that the solution in the reactor flows through the granular m...

Embodiment 2

[0031] (1) Process the coal gangue power generation ash in the drum type tank mill for 1 hour, carry out selective crushing and screening, and obtain four particle sizes of <0.5, 0.5-1, 1-3, and 3-8mm.

[0032] (2) Prepare a sodium hydroxide solution with a mass concentration of 10%.

[0033] (3) According to the solid-to-liquid ratio of 1g:2mL, particles of different particle sizes and sodium hydroxide solution were added to the reactor.

[0034] (4) Heat the material in the reactor to 90°C, keep the temperature for 36 hours, and use a pump to extract the solution from the bottom of the reactor to the top of the reactor during the reaction, so that the solution in the reactor flows through the granular material in a seepage manner, Realize liquid mixing during the reaction process, and promote the active silicon-aluminum components in the particles to crystallize and grow 4A zeolite in the sodium hydroxide solution.

[0035] (5) After the reaction, the particles are taken out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com