Double-layer composite support for establishing full-thickness skin and preparation method of double-layer composite support

A double-layer compound, full-thickness skin technology, applied in medical science, prostheses, etc., can solve the problems of long culture period of full-thickness skin model, poor mechanical properties of collagen gel scaffold, easy enzymatic hydrolysis, etc., and achieve tissue culture cycle Short, low cost, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] This specific embodiment discloses a method for preparing a double-layer composite scaffold for constructing full-thickness skin, including:

[0049] Step 1, mixing degradable protein with citric acid solution and freezing at low temperature, followed by vacuum freeze-drying to obtain a porous sponge precursor, and cross-linking the porous sponge precursor at high temperature to obtain a porous sponge scaffold;

[0050] Step 2, electrospinning the biodegradable fiber on the surface of the porous sponge support to obtain a nanofiber layer;

[0051] Step 3: After cross-linking the porous sponge scaffold with the nanofiber layer attached to the surface, a double-layer composite scaffold for constructing full-thickness skin is prepared.

[0052] Wherein, the degradable protein includes one or more of gelatin, collagen, silk protein, elastin and fibrin.

[0053] Wherein, the biodegradable fiber includes one or more of gelatin, collagen, silk protein, polylactic acid, polyam...

Embodiment 1

[0061] The preparation method of the double-layer composite scaffold for constructing full-thickness skin according to the embodiment of the present invention is as follows:

[0062] (1) Mix liquid polydimethylsiloxane (PDMS) and curing agent in a mass ratio of 5:1, stir and mix well, weigh 10g and completely cover the bottom area of 125cm 2 In a circular dish, vacuum out the air bubbles and put it in an oven at 80°C to cure polydimethylsiloxane (PDMS), then punch holes with a circular punch with a diameter of 12cm, and then punch holes with a circular hole with a diameter of 8cm The ring-shaped PDMS is obtained by punching holes, and finally the surface is modified with a plasma surface processor to form a mold.

[0063] (2) Dissolve a certain amount of gelatin and citric acid in deionized water, wherein the solid content of gelatin is 1%, and the solid content of citric acid is 0.1%. Stir evenly with a magnetic stirrer at room temperature to obtain a gelatin solution , ad...

Embodiment 2

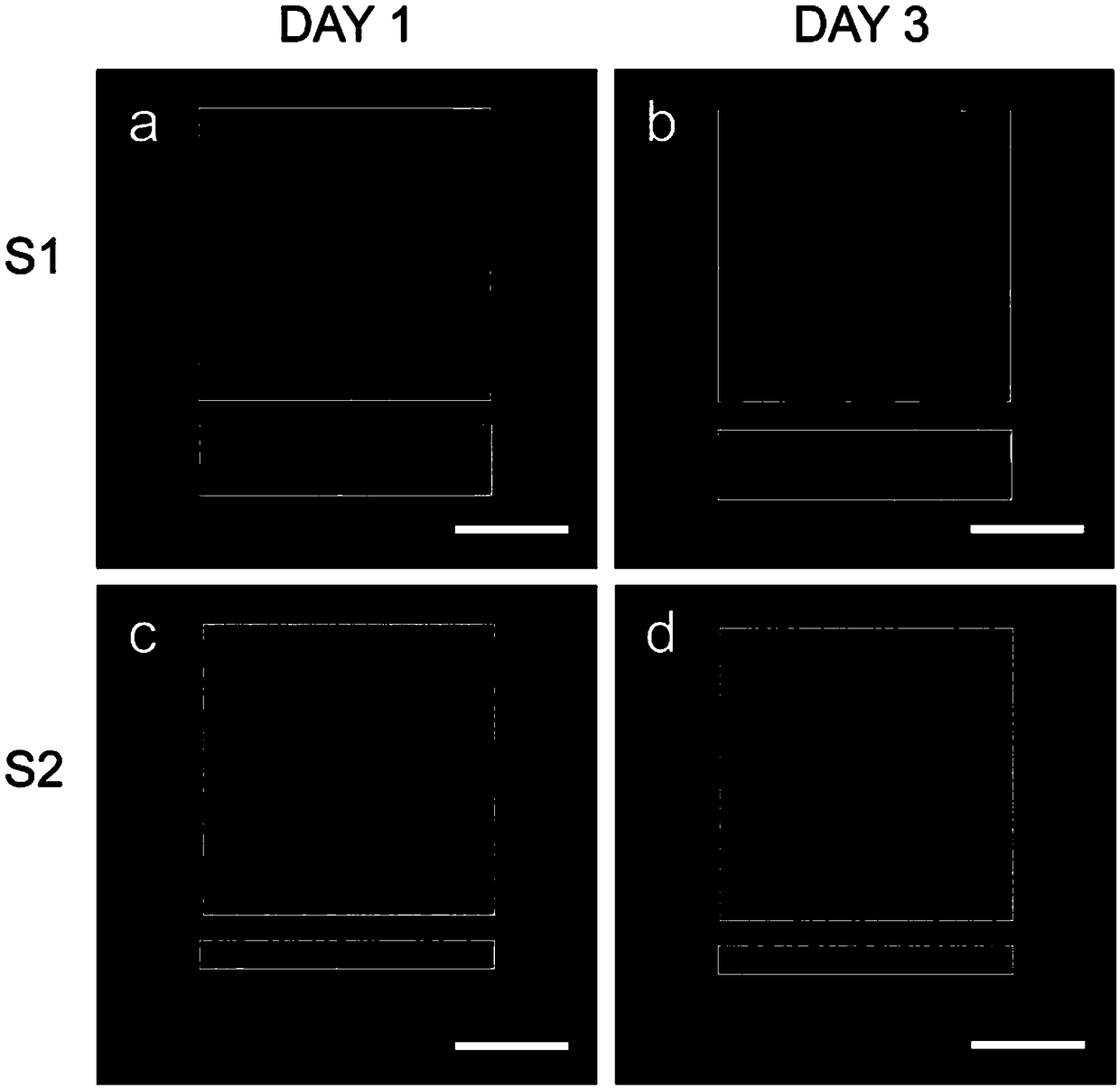

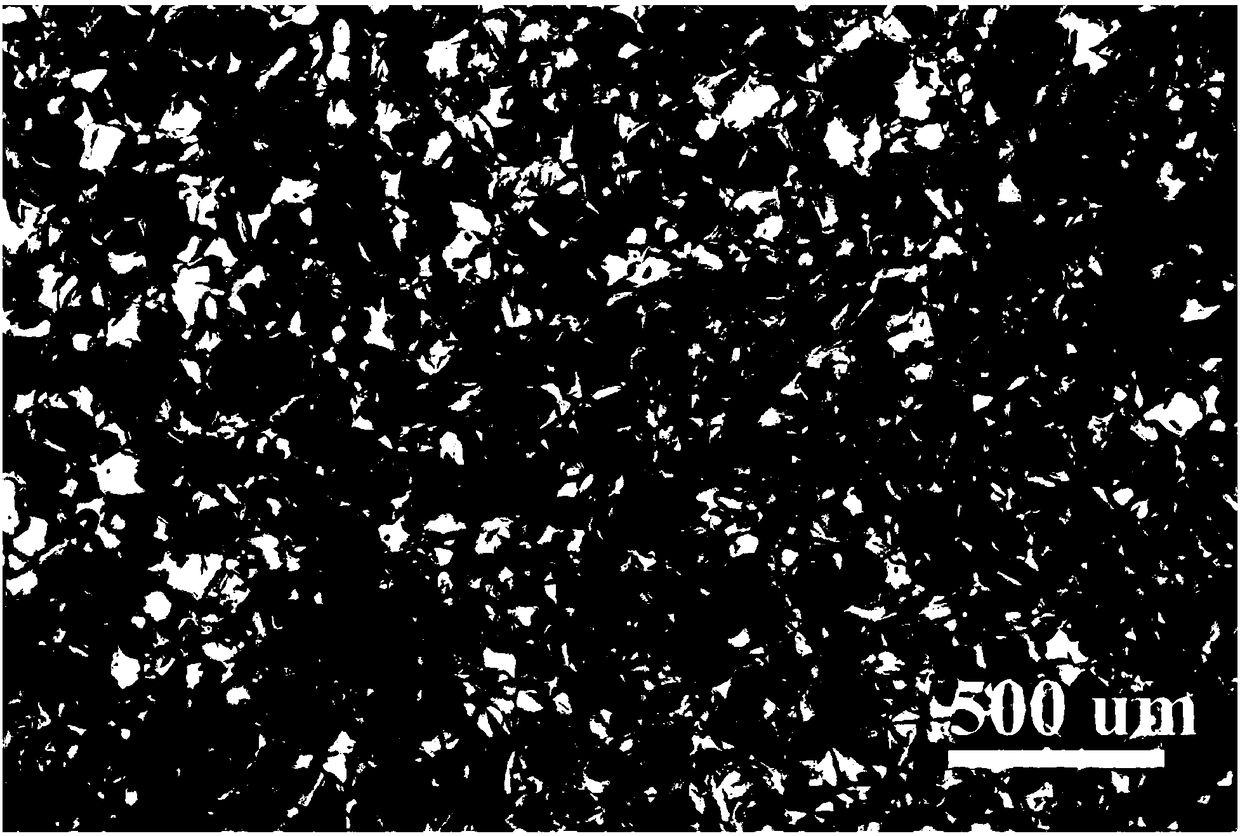

[0071] This example uses the double-layer composite scaffold for constructing full-thickness skin prepared in Example 1, the gelatin porous scaffold of the prior art and human keratinocytes to construct full-thickness skin. Figure 4 and Figure 5For the experimental results, Figure 4 Human keratinocytes were simultaneously seeded on the porous sponge scaffold (S1) and the nanofibrous layer (S2) of the two-layer composite scaffold for constructing full-thickness skin one day and three days later Electron microscope images, as can be seen from the figure, Figure 4 In (a) and (b), the mass is the form of keratinocytes adhering and proliferating on the S1 porous sponge scaffold; (c) and (d), the black sheet-like part is the form of keratinocytes on the S2 nanofiber layer, wherein The raised single globular structure is the nucleus. Inoculation of human keratinocytes in S2 compared with S1, the cells on the surface of the S2 nanofiber layer adhered better and the nanofibers p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com