High-polymer-resin resistance-reducing agent and preparation and use method thereof

A technology of polymer resin and resistance reducing agent, applied in cable/conductor manufacturing, organic material conductors, electrical components, etc., can solve the problems of toxicity and corrosion, inconvenient construction, inability to be effective for a long time, etc., to avoid corrosion and grounding resistance. The effect of stability, saving transportation and handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

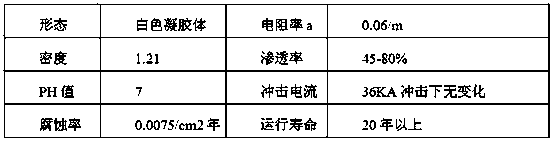

Image

Examples

Embodiment 1

[0046] A polymer resin resistance reducing agent, including sodium nitrite, polyacrylamide, ammonium persulfate, methylene bisacrylamide, and triethanolamine; the ratio of each component is as follows:

[0047] Polyacrylamide 25-35%;

[0048] Sodium nitrite 55-65%;

[0049] Triethanolamine 2-4%;

[0050] Ammonium persulfate 2-4%;

[0051] Methylene bisacrylamide 3-6%;

[0052] The polyacrylamide is 8 million molecules of polyacrylamide.

[0053] The above components are mixed according to the proportion, and stirred evenly to prepare a powdery polymer resin resistance reducing agent. Specific steps are as follows:

[0054] 1. After selecting the raw materials sodium nitrite, polyacrylamide, ammonium persulfate, methylene bisacrylamide, and triethanolamine according to the ratio, first mix the polyacrylamide and sodium nitrite together, and add them to clean water and stir well Evenly, a mixed liquid of polyacrylamide and nitrous acid is obtained; the water added when the polyacrylamide a...

Embodiment 2

[0066] The basic structure of the second embodiment is the same as that of the first embodiment, except that the selected parameters are somewhat different. It is a polymer resin resistance reducing agent, including sodium nitrite, polyacrylamide, ammonium persulfate, and methylene bis Acrylamide, triethanolamine; the ratio of each component is as follows:

[0067] Polyacrylamide 28-32%;

[0068] Sodium nitrite 58-62%;

[0069] Triethanolamine 3-5%;

[0070] Ammonium persulfate 3-5%;

[0071] Methylene bisacrylamide 4-5%.

[0072] Further, the polyacrylamide is 8 million molecules of polyacrylamide.

[0073] The above components are mixed according to the proportion, and stirred evenly to prepare a powdery polymer resin resistance reducing agent. Others are the same as the first embodiment.

Embodiment 3

[0075] The basic structure of the third embodiment is the same as that of the first embodiment, except that the selected parameters are somewhat different. It is a polymer resin resistance reducing agent, including sodium nitrite, polyacrylamide, ammonium persulfate, and methylene bis Acrylamide, triethanolamine; the ratio of each component is as follows:

[0076] Polyacrylamide 31%;

[0077] Sodium nitrite 60%;

[0078] Triethanolamine 4%;

[0079] Ammonium persulfate 5%;

[0080] Methylene bisacrylamide 5%.

[0081] Further, the polyacrylamide is 8 million molecules of polyacrylamide.

[0082] The above components are mixed according to the proportion, and stirred evenly to prepare a powdery polymer resin resistance reducing agent. Others are the same as the first embodiment.

[0083] The beneficial effects of the present invention are:

[0084] The invention adopts a polymer resin resistance reducing agent. After adding water and mixing thoroughly, it is first in a liquid state, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com