Preparation method of R-3-aminobutyric acid

A kind of aminobutyric acid, R-3- technology, applied in the field of biocatalysis, to achieve the effect of high product purity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

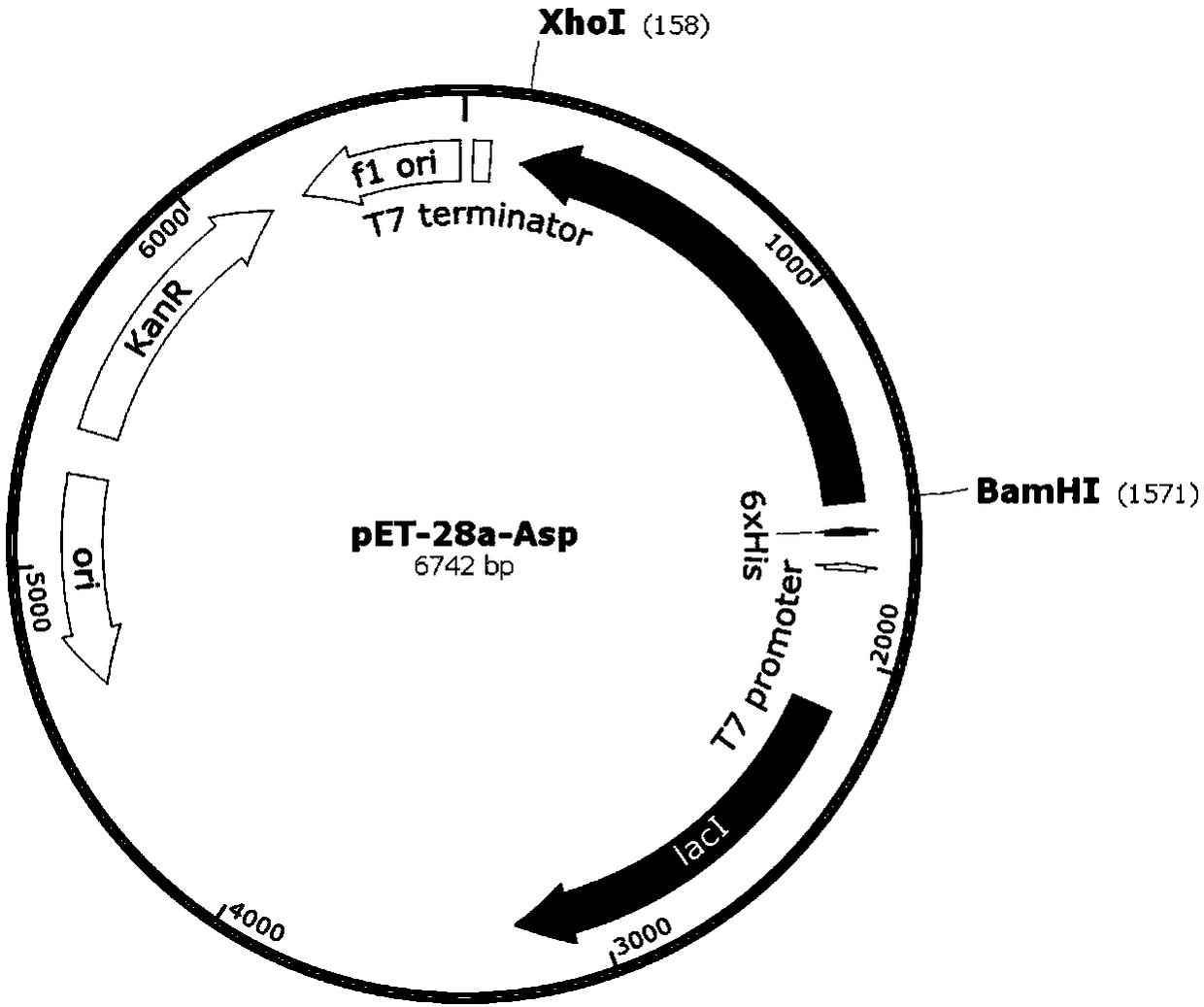

[0032] 1. Construction of Aspartase Cloning Strain

[0033] After the frozen bacillus was revived and cultured, a pair of primers were designed according to the sequence of the bacillus aspartase gene published on NCBI (such as GenBank: AB028242.1) using the bacterial solution as a DNA template:

[0034] Forward primer (ASP-P-BamH I): 5'-CGCGGATCCATGAATACCGATGTTCGT-3';

[0035] Reverse primer (ASP-R-Xho I): 5'-CCGCTCGAGTATTTTTCTTCCAGCAATTCCCGG-3';

[0036] PCR amplification was then carried out, and the reaction conditions were pre-denaturation at 94°C for 5 minutes, followed by 30 cycles (94°C for 30s, 59°C for 30s, 72°C for 1.5min), and 72°C for 10 minutes.

[0037]After the completion of PCR, gel verification and product recovery were carried out. Subsequently, the target fragment and the pET-28a(+) plasmid were digested by a double enzyme digestion system composed of BamH I and Xho I. After the reaction, the digested product was recovered, and then the digested target ...

Embodiment 2

[0044] Example 2 1000L system biocatalytic reaction

[0045] In the 1000L catalytic system, add 250kg of crotonic acid, 2.4kg of magnesium sulfate, 58kg of ammonium sulfate, then adjust the pH to 9.0 with ammonia water, stir at 40°C, add 10kg of aspartase sludge obtained in Example 1 above, and start reaction. After 12 hours of reaction, the concentration of R-3-aminobutyric acid in the solution can reach 294 g / L, and the conversion rate can reach more than 98%.

[0046] Please refer further Figure 3 to Figure 5 as shown, image 3 For adding the substrate and adjusting the pH, the liquid phase chromatogram, Figure 4 The liquid phase chromatogram of reaction 4h shows that the reaction speed is very fast. Figure 5 It is the liquid phase spectrum when reacting 12h, can find out from this figure that the substrate has been reacted substantially, and the residue of substrate is very low.

[0047] After the reaction is over, the reaction solution is treated with a microfiltr...

Embodiment 3

[0049] Example 3 1000L system biocatalytic reaction

[0050] In a 1000L catalytic system, add 270kg of crotonic acid, 2.4kg of magnesium sulfate, 72.5kg of ammonium acetate, adjust the pH to 9.2 with ammonia water, stir at 38°C, add 11kg of aspartase sludge, and start the reaction. After 12 hours of reaction, the concentration of R-3-aminobutyric acid in the solution can reach 319 g / L, and the conversion rate can reach more than 98%.

[0051] After the reaction is over, the reaction solution is treated with a microfiltration membrane to retain aspartase sludge and most of the enzyme protein, and the supernatant is passed through a nanofiltration membrane to remove SO 4 2- and most pigments. For microfiltration, microfiltration membranes with a relative molecular weight greater than 3000-5000 Daltons are selected for separation, and nanofiltration is used for separation with sodium filtration membranes with a relative molecular weight greater than 120-200 Daltons. The obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com