Production device and preparation method for compound biodiesel

A technology for biodiesel and production equipment, which is applied in the fields of biofuel, fat oil/fat refining, petroleum industry, etc., can solve the problems of high synthesis process conditions, insufficient reaction and high economic cost, achieve low economic cost and avoid loss of raw materials , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described below in conjunction with specific embodiments.

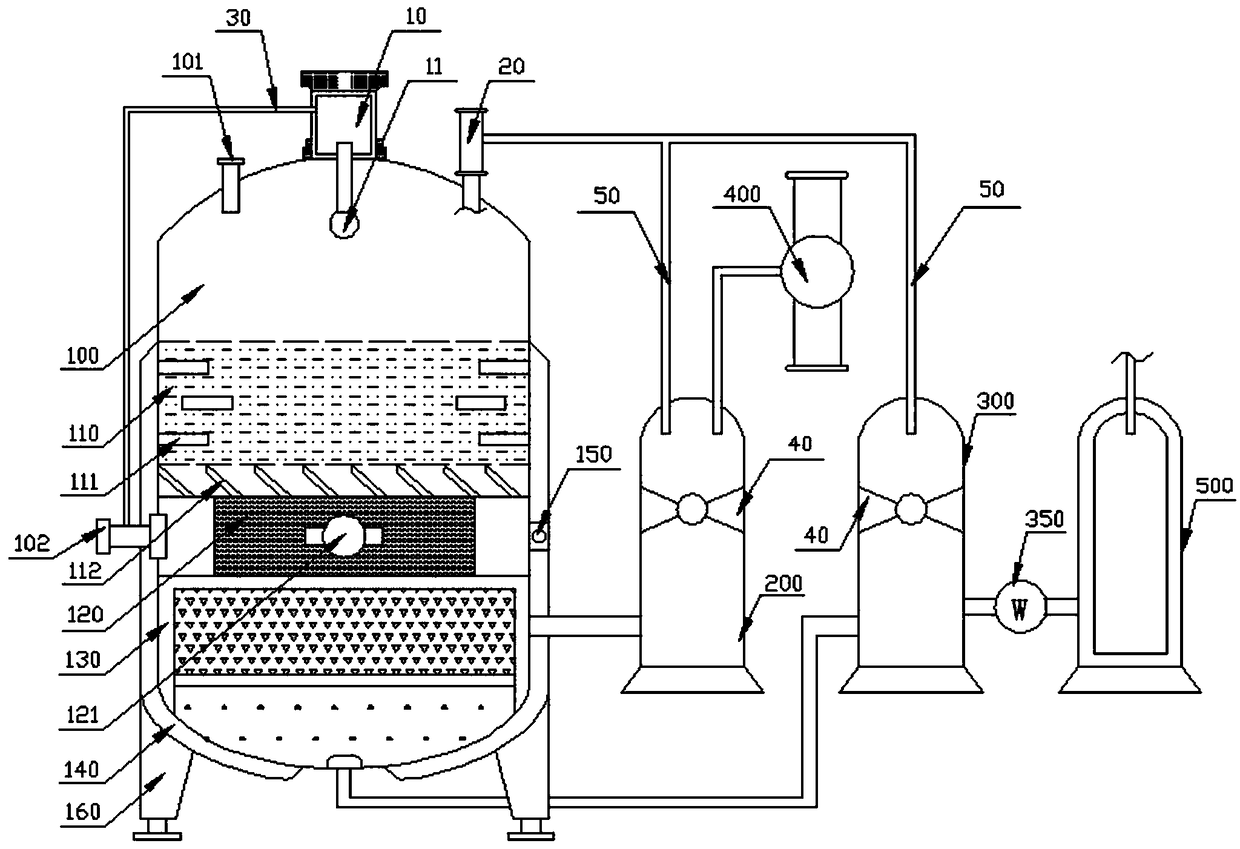

[0022] Such as figure 1 Shown is a schematic structural diagram of the production device for the composite biodiesel of the present invention.

[0023] The production device of the composite biodiesel of the present invention comprises a reactor 100, the top of the reactor 100 is provided with a grease inlet 101, and the middle part of the side wall of the reactor 100 is provided with a methanol inlet 102, and the inside of the reactor 100 is viewed from above. A catalyst reaction layer 110, a high-energy static mixing layer 120, and a static layered kettle 130 are arranged in sequence downwards, and an ultrasonic cross-flow plate 111 is arranged in the catalyst reaction layer 110 (to increase the collision between reactant molecules and ensure the reaction between the reactants. Fully contact between), the high-energy static mixing layer 120 is provided with a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com