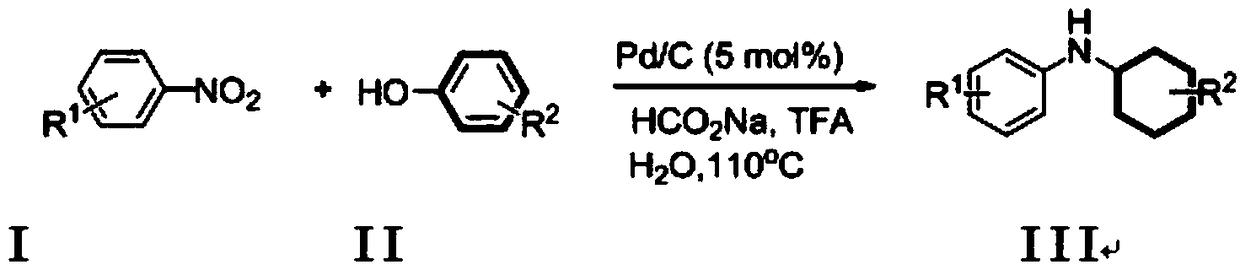

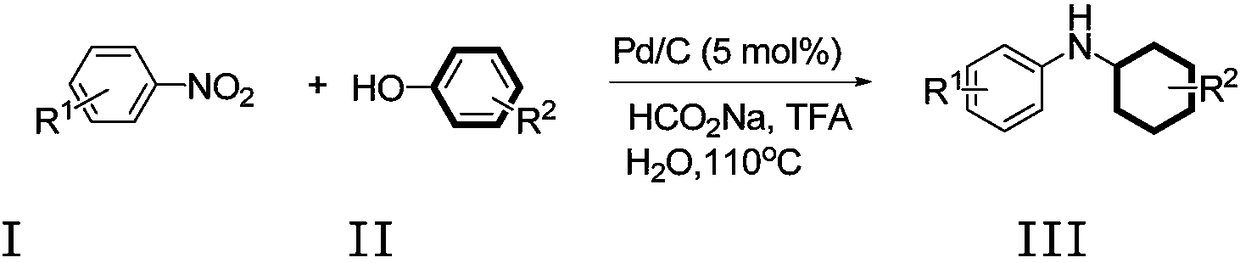

Preparation method of substituted secondary aromatic amine compound

A technology for aromatic amines and compounds, which is applied in the field of preparation of secondary aromatic amine compounds, can solve the problems of harsh reaction conditions, high energy consumption, and high risk, and achieve the effects of mild reaction conditions, easy raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]

[0058] At room temperature, 29.5 mg of nitrobenzene, 18.8 mg of phenol, 10.6 mg of palladium / carbon catalyst (10% content of palladium) and 122.4 mg of sodium formate were successively added into a 15 mL reaction tube, and three times of argon displacement were performed, and then trifluoroacetic acid ( 44.4vL) and 1mL of water, mix well. The reaction was stirred at 110° C. for 14 hours. After the reaction was completed, the palladium / carbon catalyst was filtered out, and the filter cake was washed with ethyl acetate, dried and recycled for reuse. The filtrate was extracted with ethyl acetate, and the extract was concentrated to solvent-free under vacuum (0.08Mpa) to obtain the crude product, which was then washed with a mixed eluent of petroleum ether and ethyl acetate with a volume ratio of 10:1, and the silica gel column Flash column chromatography obtained 28.7 mg of the secondary aromatic amine product of this example, with a yield of 82%.

[0059] 1 H NMR (...

Embodiment 2

[0061]

[0062] At room temperature, 32.9 mg of p-methylnitrobenzene, 18.8 mg of phenol, 10.6 mg of palladium / carbon catalyst (10% content of palladium) and 122.4 mg of sodium formate were successively added into a 15 mL reaction tube, and three Fluoroacetic acid (44.4vL) and 1mL of water, mix well. The reaction was stirred at 110° C. for 14 hours. After the reaction was completed, the palladium / carbon catalyst was filtered out, and the filter cake was washed with ethyl acetate, dried and recycled for reuse. The filtrate was extracted with ethyl acetate, and the extract was concentrated to solvent-free under vacuum (0.08Mpa) to obtain the crude product, which was then washed with a mixed eluent of petroleum ether and ethyl acetate with a volume ratio of 10:1, and the silica gel column Flash column chromatography obtained 31.4 mg of the secondary aromatic amine product of this example, with a yield of 83%.

[0063] 1 H NMR (400MHz, CDCl 3 ):7.00(d, J=8.1Hz, 2H), 6.56(d, J...

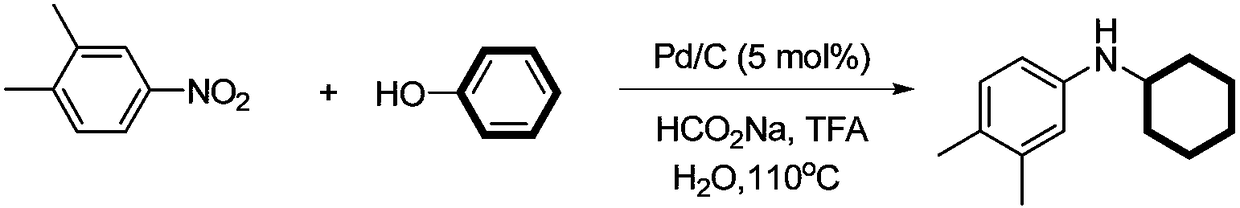

Embodiment 3

[0065]

[0066] At room temperature, 32.9 mg of m-methylnitrobenzene, 18.8 mg of phenol, 10.6 mg of palladium / carbon catalyst (10% content of palladium) and 122.4 mg of sodium formate were successively added into a 15 mL reaction tube, and three Fluoroacetic acid (44.4vL) and 1mL of water, mix well. The reaction was stirred at 110° C. for 14 hours. After the reaction was completed, the palladium / carbon catalyst was filtered out, and the filter cake was washed with ethyl acetate, dried and recycled for reuse. The filtrate was extracted with ethyl acetate, and the extract was concentrated to solvent-free under vacuum (0.08Mpa) to obtain the crude product, which was then washed with a mixed eluent of petroleum ether and ethyl acetate with a volume ratio of 10:1, and the silica gel column Flash column chromatography obtained 30.6 mg of the secondary aromatic amine product of this example, with a yield of 81%.

[0067] 1 H NMR (400MHz, CDCl 3 ):7.08(t,J=7.4Hz,2H),6.53(t,J=7.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com