Iron ion-doped nanometer manganous-manganic oxide/multilayer graphene composite material and preparation method thereof, and lithium battery using same

A technology of multi-layer graphene and trimanganese tetroxide, which is applied in the field of materials, can solve the problems of long preparation period and complicated preparation process, and achieve the effect of easy process, simple preparation process and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] see figure 1 , which is a flow chart of steps for the preparation method of iron ion-doped trimanganese tetraoxide / multilayer graphene composite material according to an embodiment of the present invention, which includes the following steps:

[0032] S10, measure dimethylformamide DMF and distilled water with a volume ratio of 8:2, mix them as a mixed solvent, and the sum of their volumes is used to calculate the concentration of other additives;

[0033] S20, adding expanded graphite and ultrasonically oscillating for 2-5 hours to obtain a mixed solution of multilayer graphene;

[0034] S30, add manganese acetate tetrahydrate and ferrous chloride tetrahydrate to the multi-layer graphene mixed solution, stir at a constant temperature of 30°C for 5-10 minutes, pour the solution into a hydrothermal reaction kettle, and keep it warm at a temperature of 100°C-130°C Cool to room temperature after 2-5 hours;

[0035] S40, taking out the reactants, washing them by centrifu...

Embodiment 1

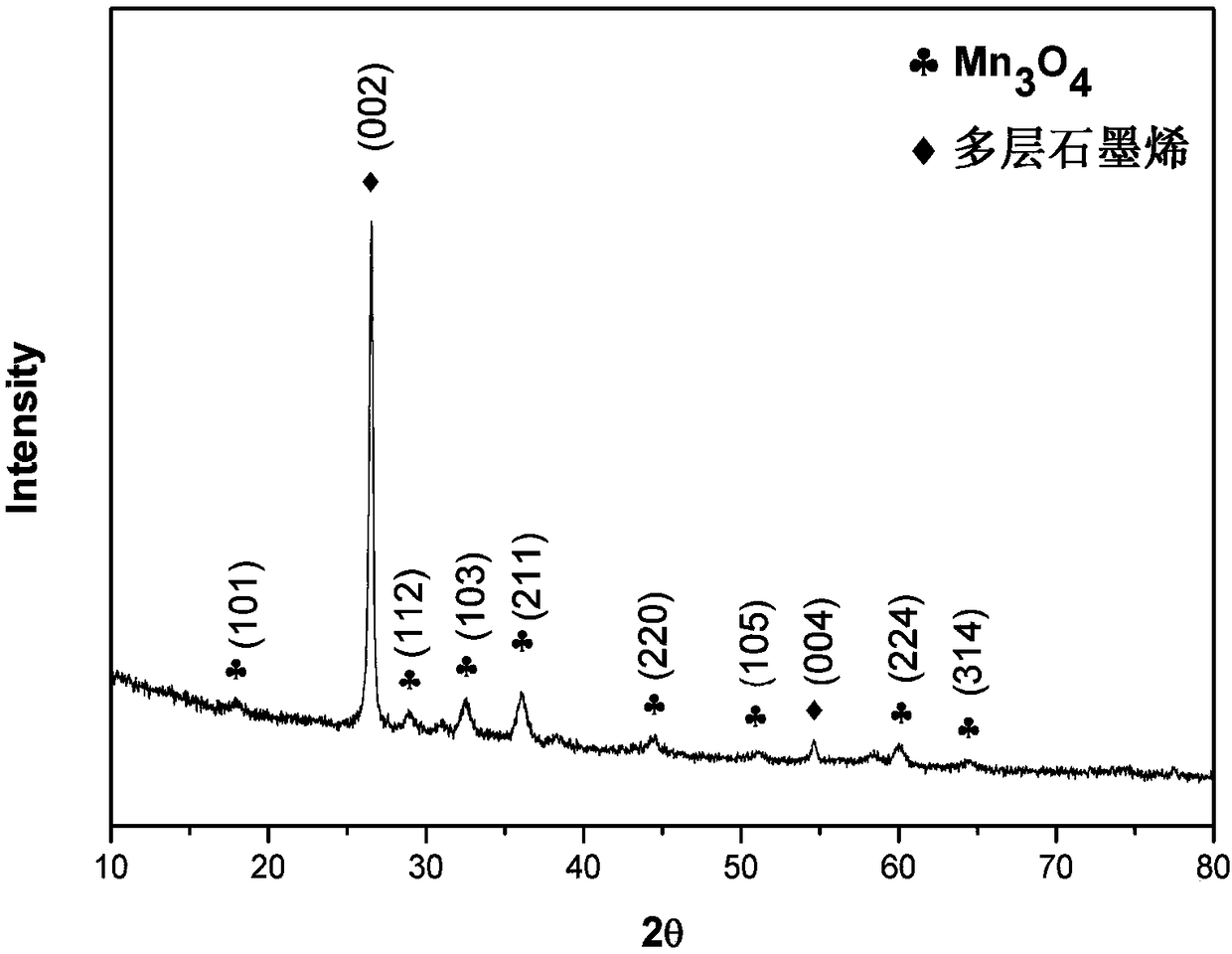

[0038] Measure and mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 20mg of expanded graphite, and ultrasonically vibrate for 2 hours to obtain a multilayer graphene mixed solution. Add 116mg Mn(Ac) to the mixed solution 2 4H 2 O and 5mg Fe(Cl) 2 4H 2 O was stirred for 10 minutes; the solution was poured into the hydrothermal reactor, so that the filling degree of the solution in the hydrothermal reactor was 45%. Keep warm at 100°C for 2 hours and then cool to room temperature; take out the reactants and wash them with alcohol and distilled water for 3 times, and finally dry them in a drying oven at 60°C for 24 hours to obtain iron-doped trimanganese tetraoxide / multilayer graphene composite Material. see figure 2 and image 3 , which are the XRD pattern and scanning electron microscope pattern of the iron-doped trimanganese tetraoxide / multilayer graphene composite, respectively, from image 3 It can be seen that the distribution density of manganese tetr...

Embodiment 2

[0040] Measure and mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 20mg of expanded graphite, and ultrasonically vibrate for 3 hours to obtain a multilayer graphene mixed solution. Add 110mg Mn(Ac) to the mixed solution 2 4H 2 O and 10mg Fe(Cl) 2 4H 2 O was stirred for 5 minutes; the solution was poured into the hydrothermal reactor, so that the filling degree of the solution in the hydrothermal reactor was 45%. Keep warm at 100°C for 3 hours and then cool to room temperature; take out the reactants and wash them with alcohol and distilled water for 4 times, and finally dry them in a drying oven at 60°C for 24 hours to obtain iron-doped trimanganese tetraoxide / multilayer graphene composite Material. see Figure 4 , which is the scanning electron microscope image of iron-doped trimanganese tetraoxide / multilayer graphene composite material, from Figure 4 It can be seen that trimanganese tetraoxide particles are evenly distributed on the surface of graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com