Slicing improvement method based on cross-linked cable slicer

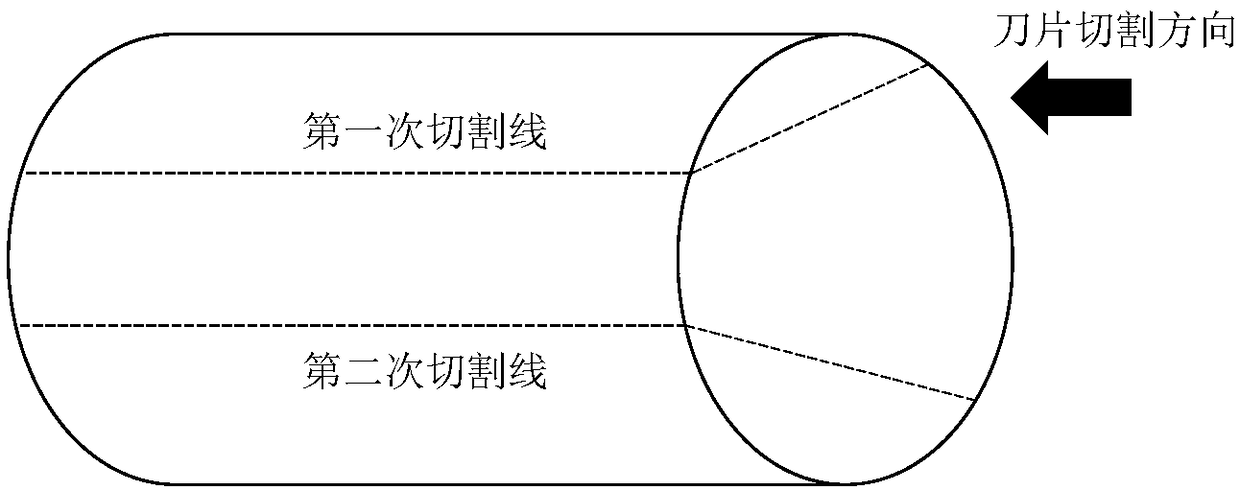

A technology of cross-linked cables and slicers, applied in sampling devices and other directions, can solve the problems of large cross-sectional area, thick samples, broken blades, etc., and achieve the effect of improving thickness accuracy, reducing contact area, and protecting blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] According to the needs of the experiment: Obtain a 0.4mm sample of the required cable near the inner insulating layer. The range of the microtome in this experiment is 5 large divisions of 1 mm, and a slice of 0.4 mm can be obtained by adjusting 2 divisions.

[0025] 1. Select the 110kV XLPE cable that has been in operation for 15 years on Sumitomo Kashobun Panwu Line in Japan as the slicing object, cut the cable, and remove the outer sheath to obtain a three-layer extruded part with a conductor structure about 15cm long.

[0026] 2. Fix the above cable on the cross-linked polyethylene slicer, first adjust the rotary scale handwheel of the slicer, so that the blade just touches the surface of the outer semi-conductive layer of the cable, and then manually drag the cable to a position where the blade cannot touch. Adjust the rotating and lifting scale handwheel of the microtome with 5 large divisions to move the blade down about 1mm, and then rotate the start button to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com