Production method for high strength low entrainment pipeline steel

A production method and pipeline steel technology, applied in the field of metal materials, can solve problems such as unstable mechanical properties, low product yield, and difficult process control, and achieve the effects of reducing the formation of inclusions, improving production efficiency, and saving process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

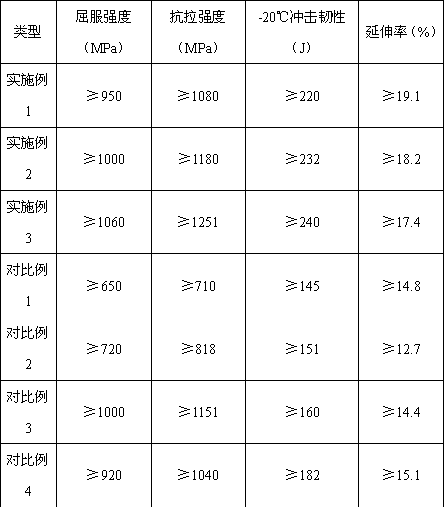

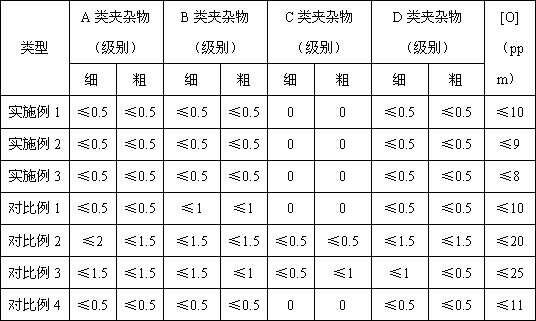

Examples

Embodiment 1

[0050] A production method of high-strength and low-inclusion pipeline steel, characterized in that: the composition of pipeline steel is C 0.065%, Si0.1%, Mn 1.75%, P≤0.015%, S≤0.005%, Nb 0.04%, V 0.02% , Ti 0.001%, Al≤0.050%, Cr 0.5%, Mo 0.25%, Ni 0.3%, Cu 0.15%, W 0.005%, Hf 0.0001%, rare earth (La+Ce) 0.0001%, La: Ce mass ratio is 4 -5:1, B 0.0001%, N 0.001%, the balance is Fe and unavoidable impurity elements, the process route includes: hot metal desulfurization treatment → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling → Heat treatment; the core steps are as follows:

[0051] (1) Desulfurization treatment of molten iron;

[0052] (2) Converter smelting: Select molten iron and scrap steel with S content ≤0.005% and C content ≤0.08%, the mass ratio of molten iron to scrap steel is 9:1, add molten iron first, then add scrap steel, adopt double slag operation, converter bottom blowing Argon and nitrogen, the initial nitrogen intens...

Embodiment 2

[0060] A production method of high-strength and low-inclusion pipeline steel, characterized in that: the composition of pipeline steel is C 0.067%, Si0.15%, Mn 1.76%, P≤0.015%, S≤0.005%, Nb 0.05%, V 0.025% , Ti 0.003%, Al≤0.050%, Cr 0.6%, Mo 0.28%, Ni 0.32%, Cu 0.17%, W 0.007%, Hf 0.0003%, rare earth (La+Ce) 0.0003%, La: Ce mass ratio is 4 -5:1, B 0.0003%, N 0.003%, the balance is Fe and unavoidable impurity elements, the process route includes: hot metal desulfurization treatment → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling → Heat treatment; the core steps are as follows:

[0061] (1) Desulfurization treatment of molten iron;

[0062] (2) Converter smelting: Select molten iron and scrap steel with S content ≤0.005% and C content ≤0.08%, the mass ratio of molten iron to scrap steel is 9:1, add molten iron first, then add scrap steel, adopt double slag operation, converter bottom blowing Argon and nitrogen, the initial nitrogen int...

Embodiment 3

[0070] A production method of high-strength and low-inclusion pipeline steel, characterized in that: pipeline steel components are C 0.07%, Si0.2%, Mn 1.78%, P≤0.015%, S≤0.005%, Nb0.06%, V 0.03 %, Ti 0.005%, Al≤0.050%, Cr 0.65%, Mo 0.3%, Ni 0.35%, Cu 0.19%, W 0.008%, Hf 0.005%, rare earth (La+Ce) 0.0005%, La: Ce mass ratio is 4-5:1, B 0.0005%, N 0.005%, the balance is Fe and unavoidable impurity elements, the process route includes: hot metal desulfurization treatment → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling →Heat treatment; the core steps are as follows:

[0071] (1) Desulfurization treatment of molten iron;

[0072] (2) Converter smelting: Select molten iron and scrap steel with S content ≤0.005% and C content ≤0.08%, the mass ratio of molten iron to scrap steel is 9:1, add molten iron first, then add scrap steel, adopt double slag operation, converter bottom blowing Argon and nitrogen, the initial nitrogen intensity is 0.12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com