Oil-pollution-resistant heat-sealing high-barrier thin film

An anti-oil stain and high-resistance technology, applied in non-polymer organic compound adhesives, packaging, wrapping paper, etc., can solve the problems of package damage, oil stain residue, material waste, etc., achieve good oleophobic effect and easy to clean , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

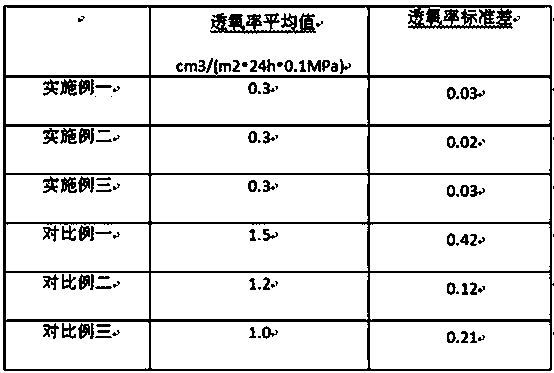

Embodiment 1

[0024]An oil-resistant heat-sealed high-barrier film, its structure is: PA1 / T1 / PP / T2 / PA2 / C / PA3 / T3 / PE1 / PE2 / PE3, PE3 is the outer layer in contact with the outside world during packaging, and PA1 is the outer layer of the packaging The inner layer that is in contact with the package, PP material is the auxiliary layer, C is the gas barrier layer, T1, T2, T3 are the adhesive layer, PA1, PA2, PA3 are the oil resistance layer, PE1, PE2, PE3 are the heat sealing layer barrier layer;

[0025] The gas barrier layer is mainly composed of the following components in parts by weight: 10 parts of ethylene-vinyl alcohol copolymer, 9 parts of polyvinyl alcohol, 11 parts of isocyanurate, 16 parts of 4-tert-butylbenzoic acid, polysilicon 6 parts of azane, 16 parts of methacrylamide;

[0026] The adhesive layer is mainly composed of the following components in parts by weight: 15 parts of ethylene-vinyl acetate copolymer, 16 parts of ethylhexyl acrylate, 9 parts of Weirong fiber, 19 parts of ...

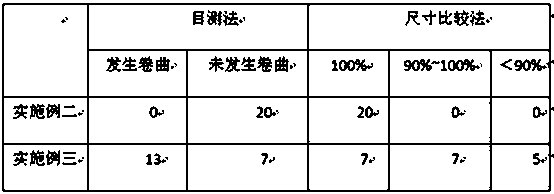

Embodiment 2

[0038] The technical scheme of the present invention: an anti-oil pollution heat-sealed high barrier film, its structure is PA1 / T1 / PP / T2 / PA2 / C / PA3 / T3 / PE1 / PE2 / PE3, PE3 is the outer surface contacting with the outside world during packaging. PA1 is the inner layer in contact with the packaging during packaging, PP material is the auxiliary layer, C is the gas barrier layer, T1, T2, T3 are adhesive layers, PA1, PA2, PA3 are oil-resistant layers, PE1, PE2, PE3 is a heat-sealed high-resistance layer;

[0039] The gas barrier layer is mainly composed of the following components in parts by weight: 15 parts of ethylene-vinyl alcohol copolymer, 10 parts of polyvinyl alcohol, 12 parts of isocyanurate, 21 parts of 4-tert-butylbenzoic acid, polysilicon 10 parts of azane, 23 parts of methacrylamide;

[0040] The adhesive layer is mainly composed of the following components in parts by weight: 20 parts of ethylene-vinyl acetate copolymer, 19 parts of ethylhexyl acrylate, 10 parts of Weiro...

Embodiment 3

[0052]An anti-oil stain heat-sealed high barrier film, its structure is PA1 / T1 / PP / T2 / PA2 / C / PA3 / T3 / PE1 / PE2 / PE3, PE3 is the outer layer that contacts with the outside during packaging, and PA1 is the outer layer when packaging. For the inner layer in contact with the package, PP material is the auxiliary layer, C is the gas barrier layer, T1, T2, T3 are the adhesive layer, PA1, PA2, PA3 are the anti-oil layer, PE1, PE2, PE3 are heat-sealed high-resistance layers layer;

[0053] The gas barrier layer is mainly composed of the following components in parts by weight: 20 parts of ethylene-vinyl alcohol copolymer, 12 parts of polyvinyl alcohol, 15 parts of isocyanurate, 28 parts of 4-tert-butylbenzoic acid, polysilicon 14 parts of azane, 32 parts of methacrylamide;

[0054] The adhesive layer is mainly composed of the following components in parts by weight: 25 parts of ethylene-vinyl acetate copolymer, 22 parts of ethylhexyl acrylate, 12 parts of Weirong fiber, 28 parts of carboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com