Making method of regenerated cellulose defatted emulsified sausages

A technology of regenerated cellulose and emulsified intestines, applied in the function of food ingredients, food science, application, etc., can solve the problems of high cost and increased particle size of emulsion, improve oil retention, inhibit fat oxidation, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The production method of traditional high-fat emulsified sausage is as follows:

[0018] 1) The raw materials are fresh pork hind legs and pig back fat, the visible sarcolemma and fat are removed, the blood spots are removed from the pig back fat, and the hind legs and pig back fat are minced separately.

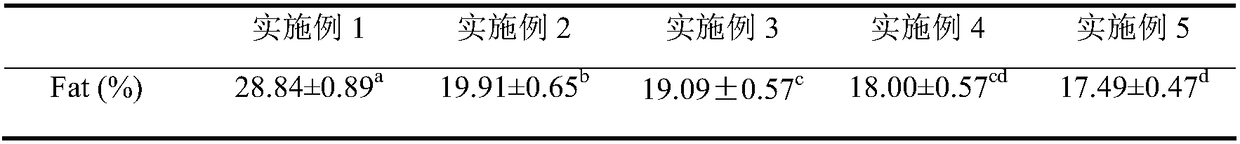

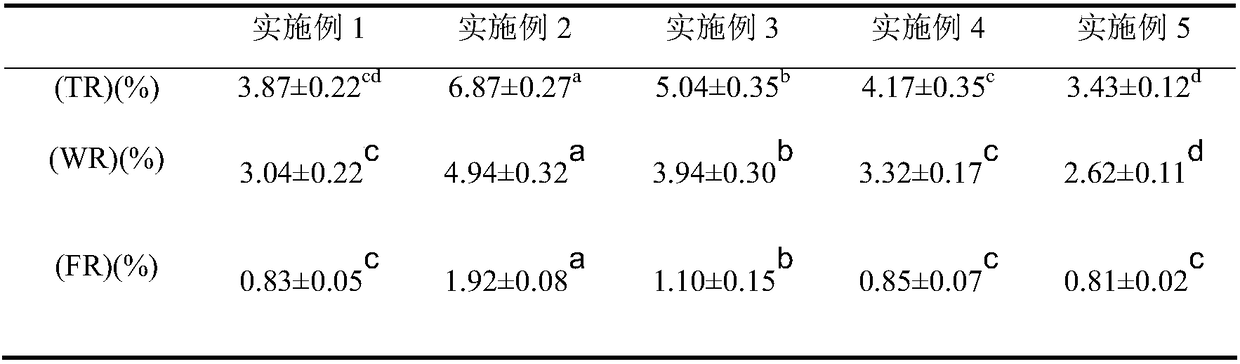

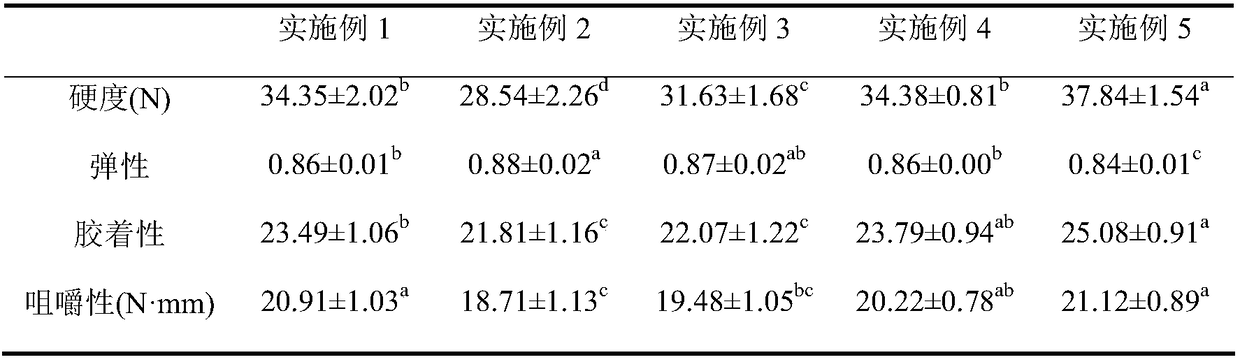

[0019] 2), in parts by mass, take 50 parts of pork hind legs, 1.5 parts of salt, 0.3 parts of sodium tripolyphosphate, 0.5 parts of sucrose, 2.4 parts of white pepper powder, 6.6 parts of ice water, place in a vacuum chopping machine Chop and mix for 1min at 1500rpm; add 30 parts of pig backfat and 6.6 parts of ice water, and chop and mix for 1min at 3000rpm; add the remaining 6.8 parts of ice water, and chop and mix for 1.5min at 3000rpm to obtain emulsified minced meat. The temperature of the emulsified minced meat is lower than 12°C. Added 30 parts of pig back fat in the implementation case 1, as a high-fat control,

[0020] 3) Collagen casings are vacuum filled ...

Embodiment 2

[0022] The production method of reduced-fat emulsified sausage is as follows:

[0023] 1), the preparation of regenerated cellulose:

[0024] Mix microcrystalline cellulose and deionized water, shake well, add 85% phosphoric acid (food grade) pre-cooled at 4°C, the ratio of microcrystalline cellulose: water: phosphoric acid is 1g: 3mL: 50mL, stir well, and get milky white fiber Suspension of phosphate phosphoric acid, cultivated in a low-temperature shaking incubator at 4°C and 150rpm for 24 hours, to obtain a transparent and viscous cellulose phosphate solution, add 200 parts of deionized water to dilute, mix well, then centrifuge at 17000g for 15min, and remove After repeated washing with water for several times, centrifugation until the pH value was constant, a regenerated cellulose gel was obtained, and the final concentration was measured to be 4.53%.

[0025] 2), preparation of emulsified sausage:

[0026] 2.1) The raw materials are fresh pork hind legs and pig back fa...

Embodiment 3

[0030] The production method of reduced-fat emulsified sausage is as follows:

[0031] 1), the preparation of regenerated cellulose:

[0032] Mix microcrystalline cellulose and deionized water, shake well, add precooling 77% phosphoric acid (food grade) at 4°C, the ratio of microcrystalline cellulose: water: phosphoric acid is 1:3.5:55, stir well, and get milky white fiber Suspension of phosphate phosphoric acid, incubate for 24 hours at 4°C, 150rpm low-temperature shaking incubator to obtain a transparent and viscous cellulose phosphate solution, add 220 parts of deionized water to dilute, mix well, and then centrifuge at 17000g for 15min, and remove clear, repeated washing with water several times, and centrifuged until the pH value was constant to obtain regenerated cellulose gel.

[0033] 2), preparation of emulsified sausage:

[0034] 2.1) The raw materials are fresh pork hind legs and pig back fat, the visible sarcolemma and fat are removed, the blood spots are removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com