Polarizing plate, method for producing polarizing plate and liquid crystal display device

A technology of a liquid crystal display device and a manufacturing method, applied in polarizing elements, chemical instruments and methods, instruments, etc., capable of solving the problems of productivity (decreased yield, reduced production efficiency, poor planarity, etc., to prevent the yield from falling) , excellent yield, and improved durability and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0159] The method for preparing the composition for a hard coat layer is not particularly limited as long as the components can be uniformly mixed, and known devices such as a paint shaker, bead mill, kneader, and mixer can be used, for example.

[0160] In addition, the method for applying the composition for a hard coat layer to the first protective film of the present invention is not particularly limited, and examples thereof include spin coating, dip coating, spray coating, die coating, and bar coating. Known wet methods such as roll coating, meniscus coater, flexographic printing, screen printing, and bead coater.

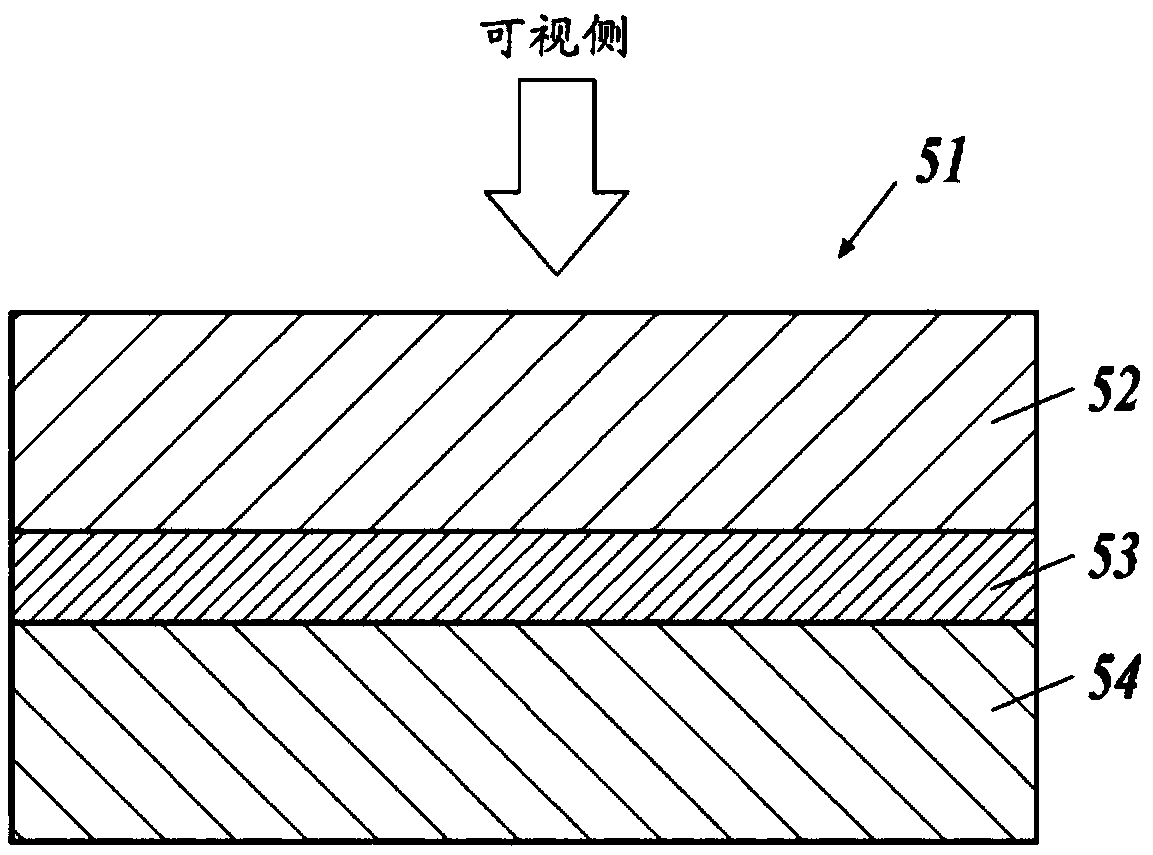

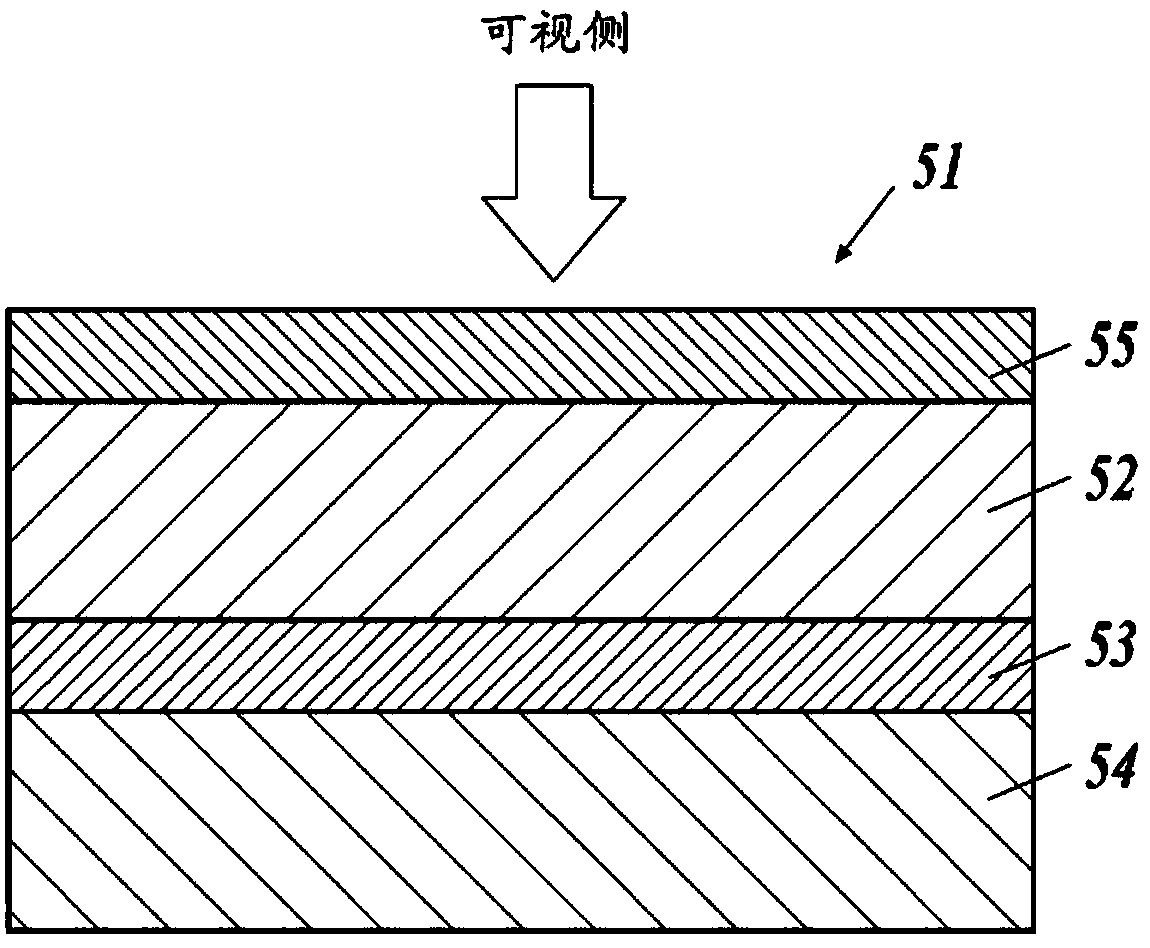

[0161] [Second protective film]

[0162] The second protective film of the present invention is characterized in that it is a light-transmitting film having a light transmittance at 380 nm of less than 50%. That is, it has a characteristic of having high ultraviolet absorption performance in the ultraviolet region.

[0163] More preferably, the second prote...

Embodiment 1

[0645] "Making of the First Protective Film"

[0646] The 1st protective films PET1-PET4 which are polyester films were produced by the following method.

[0647]〔Preparation of the first protective film PET1〕

[0648] (Preparation of Polyester Resin A)

[0649] Put 86.4 parts by mass of terephthalic acid and 64.6 parts by mass of ethylene glycol into the esterification reaction container, heat up, and heat and stir at 200°C, and at the same time, put 0.017 parts by mass of antimony trioxide and 0.064 parts by mass of magnesium acetate tetrahydrate as catalysts. parts by mass, 0.16 parts by mass of triethylamine. The pressurized esterification reaction was carried out under the conditions of a gauge pressure of 0.34 MPa and a temperature of 240°C.

[0650] Next, the esterification reaction container was returned to normal pressure, and 0.014 parts by mass of phosphoric acid was added. Furthermore, it heated up to 260 degreeC in 15 minutes, and added 0.012 mass parts of tri...

Embodiment 2

[0804] "Production of the Second Protective Film: Cycloolefin Film"

[0805] [Production of the second protective film 101 ]

[0806] (Synthesis of cycloolefin resin 1)

[0807] 8-methyl-8-methoxycarbonyltetracyclo[4.4.0.12,5.17,10]-3-dodecene (DNM) 75% by mass, dicyclopentadiene (DCP) 24% by mass, 2 - 1% by mass of norbornene, 9 parts of 1-hexene as a molecular weight modifier, and 200 parts of toluene were put into a nitrogen-substituted reaction container, and heated to 110°C. Add 0.005 parts of triethylaluminum, methanol modified WCl6 (anhydrous methanol: PhPOCl 2 : WC l6 =103:630:427 (mass ratio)) 0.005 part and reacted for 1 hour to obtain a polymer. The obtained polymer solution was put into the autoclave, and 200 parts of toluene was added thereto. Next, add the hydrogenation catalyst RuHCl(CO)[P(C 6 h 5 )] 3 0.006 parts, after heating to 90° C., put hydrogen gas into the reactor, and set the pressure to 10 MPa. Then, the pressure was kept at 10 MPa, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com