Methods and compositions for on-demand release of ClO2 gas from UV-activated chlorite ion

A technology of chlorite and composition, applied in the field of controlled release of disinfectant gas, can solve problems such as difficulty in controlling the timing of ClO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

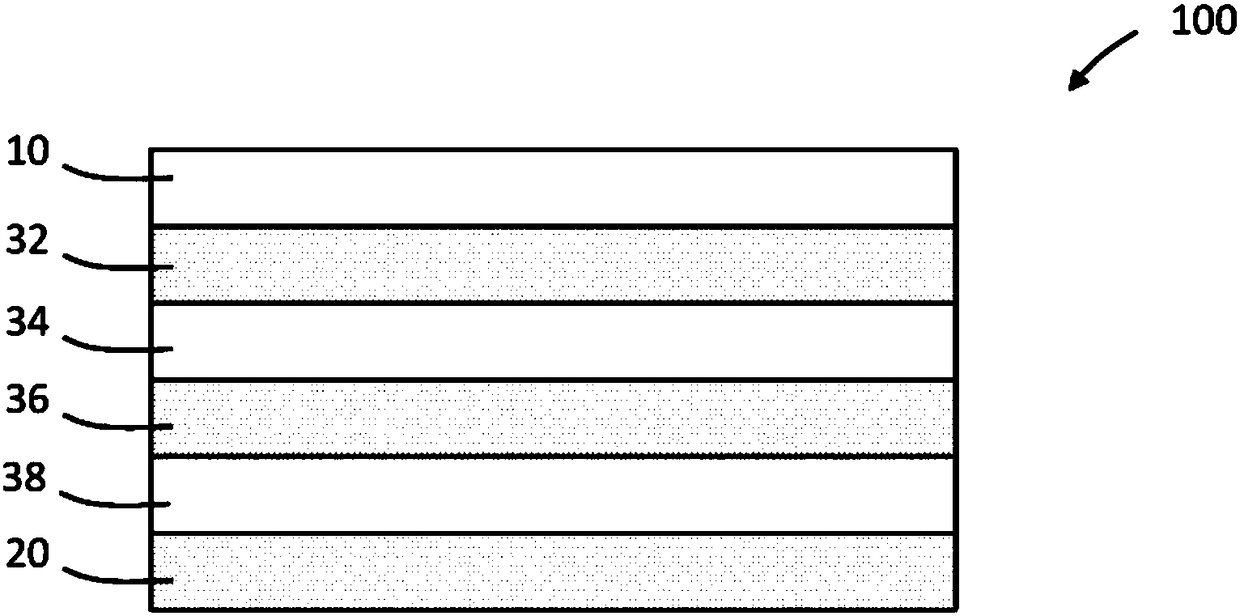

[0178] Example of Multilayer Film Embodiment - Produce Packaging Film

[0179] In some embodiments, a multilayer produce film includes a first layer and a chlorine dioxide generating layer. The chlorine dioxide generating layer comprises a polymer composition and a plurality of chlorite ions. The chlorine dioxide generating layer is substantially free of energy activated catalysts and substantially free of acid releasing compounds. In some embodiments, the plurality of chlorite ions are present in a salt selected from the group consisting of sodium chlorite, potassium chlorite, and mixtures thereof. In some embodiments, the film has at least 775 cm 3 / m 2 / 24 hours (50cm 3 / 100in 2 / 24 hours) oxygen transmission rate, such as at least 3100cm 3 / m 2 / 24 hours (200cm 3 / 100in 2 / 24 hours) oxygen transmission rate. In some embodiments, the first layer is an abuse resistant layer, wherein the abuse resistant layer is UV light transparent.

[0180] In some embodiments, t...

Embodiment 1

[0339] Example 1: 'On Demand' Release of Disinfectant Gas: From UV Activated NaClO in the Presence of Moisture 2 produce ClO 2 gas

[0340] In this exemplary embodiment, ClO is shown 2 Capable of converting solid sodium chlorite (NaClO 2 ) produced, whereby it is first "activated" with UV light under dry conditions and subsequently exposed to moisture to produce ClO at a later point in time when it is exposed to moisture 2 . This example includes continuous gas (N 2 ) to systematically investigate this phenomenon in flow cell devices. Specifically, this example demonstrates that NaClO 2 Samples can be activated by UV radiation under dry conditions to release ClO in the subsequent presence of moisture 2 . Second, it confirmed that the produced ClO 2 The amount varies as a function of the wavelength of UV radiation and moisture level. Third, it shows the total ClO from the sample 2 Production can be manipulated by varying the duration of UV exposure. Fourth, the exam...

Embodiment 2

[0362] Example 2: 'On Demand' Release of Disinfectant Gas: From NaClO-containing 2 A UV-activated polymer film generates ClO 2 gas

[0363] In this example, it demonstrates controlled ClO from a chlorite-containing polymer membrane 2 Gas released. This result shows that the polymer film introduced with chlorite ion can be used for ClO 2 controlled release. Thus, polymer films incorporating chlorite ions can be used to wrap or package products that would benefit from on-demand disinfection and / or deodorization, including without limitation medical devices or food products.

[0364] Film preparation. Polyvinyl alcohol (PVA) polymer (molecular weight=13000-23000gr / mol, Sigma Aldrich, 98% hydrolysis) and sodium chlorite (NaClO 2 ) salt (high purity grade, VWR International) was dissolved in deionized water to achieve ((0.05gr PVA-0.05gr NaClO 2 ) / 1mL solution). Fused silica substrates (cut into (2 cm × 2.5 cm) pieces) were cleaned with water, ethanol and water, then passed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com