Porous copper oxide microsphere/multilayer graphene composite material, and preparation method thereof

A multi-layer graphene and composite material technology, applied in the field of materials, can solve problems such as low electrical conductivity and limit the use of electrode materials, and achieve the effects of simple preparation method, short preparation time, and favorable industrial preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

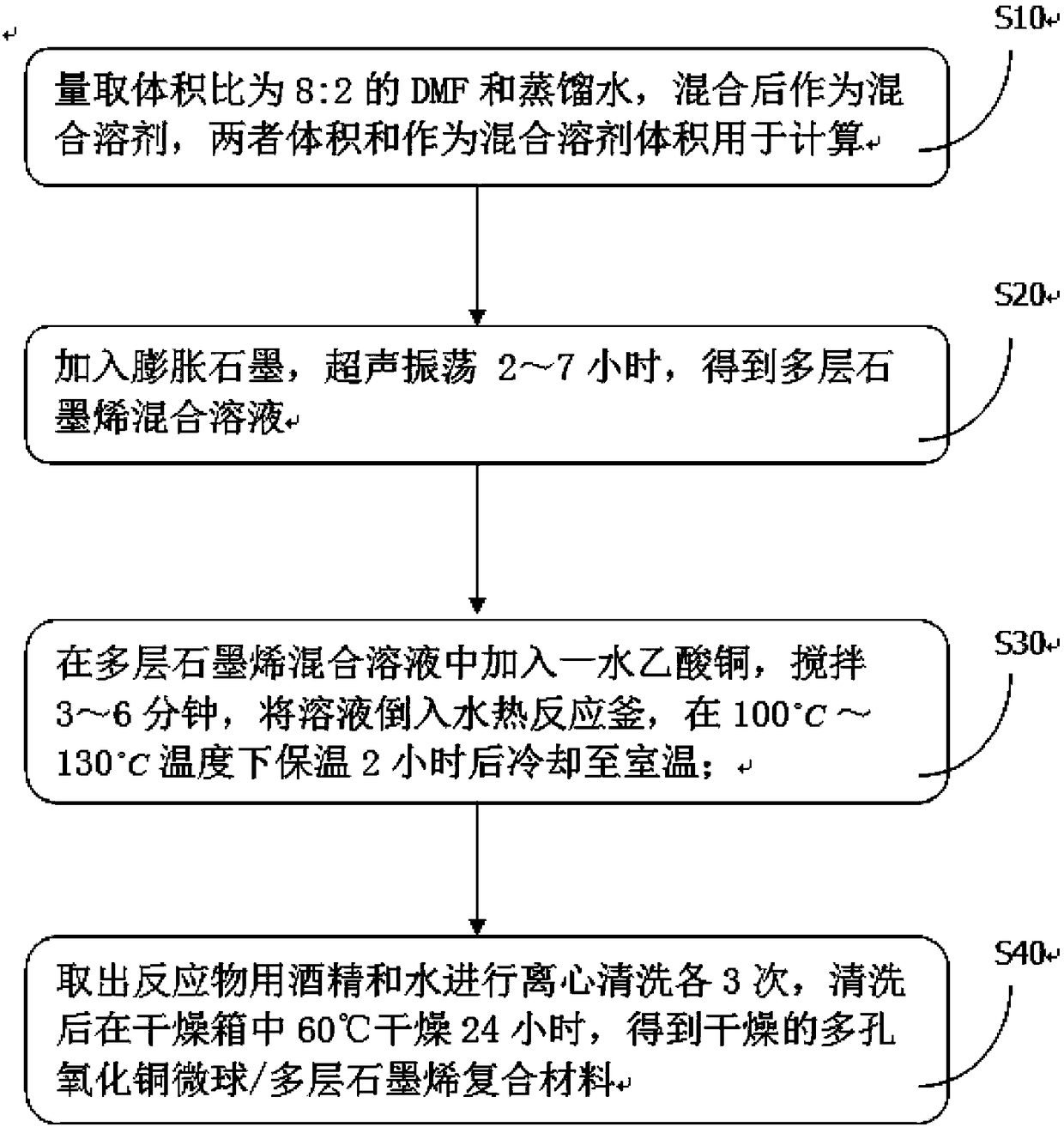

[0028] see figure 1 , which is a flow chart of the steps of the preparation method of the porous copper oxide microsphere / multilayer graphene composite material according to the embodiment of the present invention, which includes the following steps:

[0029] S10, measure DMF (dimethylformamide) and distilled water with a volume ratio of 8:2, mix them as a mixed solvent, and the volume of the two and the volume of the mixed solvent are used for calculation;

[0030] S20, adding expanded graphite and ultrasonically vibrating for 2 to 7 hours to obtain a mixed solvent of multilayer graphene;

[0031] Wherein the expanded graphite is 1.3mg / mL-2.5mg / mL relative to the mixed solvent, the oxygen content on the surface of the multilayer graphene is less than 3%, and the number of layers is less than 100.

[0032] S30, adding copper acetate monohydrate to the multilayer graphene mixed solvent, stirring for 3 to 6 minutes, pouring the solution into a hydrothermal reaction kettle, keep...

Embodiment 1

[0038] Mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 13mg of expanded graphite, and ultrasonically vibrate for 2 hours to obtain the multilayer graphene required by the present invention. Add 100mg Cu(CH 3 COO) 2 ·H 2 O was stirred for 5 minutes; the solution was poured into the hydrothermal reactor, so that the filling degree of the solution in the hydrothermal reactor was 30%. After being kept at 100°C for 2 hours, it was cooled to room temperature; the reactant was taken out and washed with alcohol and water for 3 times, and finally dried at 60°C for 24 hours in a drying oven to obtain a nano-copper oxide / multilayer graphene composite material. see figure 2 , which is the scanning electron microscope image of the nano-copper oxide / multilayer graphene composite material. It can be seen from the figure that the copper oxide particles obtained by the reaction are evenly distributed on the surface of the graphene, with a size of about 1 μm, an irregular ...

Embodiment 2

[0040] Mix 8ml of DMF and 2ml of distilled water as a mixed solvent, add 15mg of expanded graphite, and ultrasonically vibrate for 4 hours to obtain the required multilayer graphene of the present invention. Add 200mg Cu(CH 3COO) 2 ·H 2 O was stirred for 3 minutes; the solution was poured into the hydrothermal reactor, so that the filling degree of the solution in the hydrothermal reactor was 30%. After being kept at 100°C for 2 hours, it was cooled to room temperature; the reactant was taken out and washed with alcohol and water for 3 times, and finally dried at 60°C for 24 hours in a drying oven to obtain a nano-copper oxide / multilayer graphene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com