A preparation method of fully open-cell polymer foam material and corresponding foam material

A technology of foaming materials and polymers, which is applied in the field of polymer materials, can solve the problems of restricting the application range of foaming technology, the difficulty of opening pores or the opening rate on the surface of polymer foaming materials, and avoiding cost and environmental pollution. Good surface opening effect and good connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

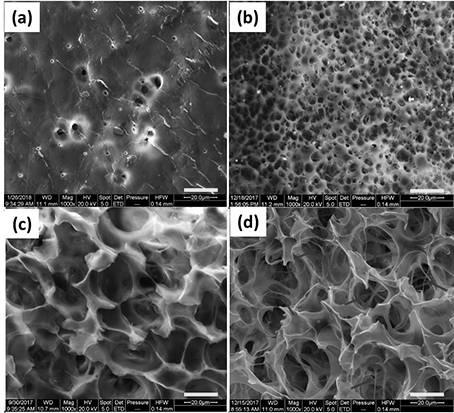

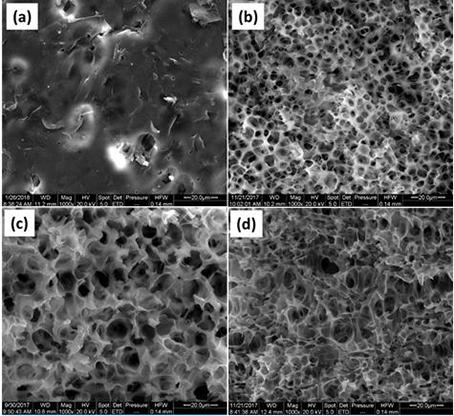

[0028] Example 1 Preparation of polycaprolactone (PCL) fully open-cell foaming material

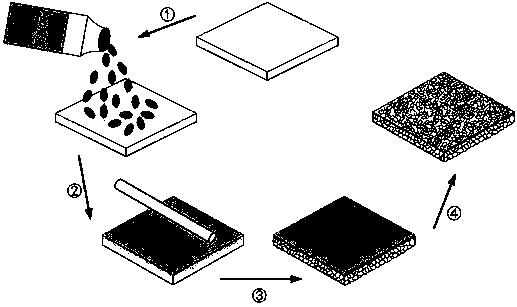

[0029] A preparation method for a fully open-cell polymer foam material, comprising the following steps:

[0030] (1) Two polymers, PCL (number average molecular weight 50,000) and PEO (number average molecular weight 100,000), are melt-blended, extruded, and granulated on a twin-screw extruder at a weight ratio of 70:30, and PEO is dispersed phase form, use a vacuum tablet press to press the PCL / PEO blend particles into a film (green body) with a thickness of 180 μm, and dry it in a vacuum drying oven for 24 hours to ensure that there is no residual moisture;

[0031] (2) Weigh 25g of PEO, put it into 75ml of deionized water, seal it and stir at 25°C for 24 hours; after obtaining a completely dissolved PEO solution with a concentration of 25WT%, use a mold to evenly coat it on PCL / PEO (70 / 30) the surface of the film material to obtain a protective body with a thickness of 20 μm PEO prot...

Embodiment 2

[0038] Example 2 Preparation of polycaprolactone (PCL) fully open-cell foaming material

[0039] A preparation method for a fully open-cell polymer foam material, comprising the following steps:

[0040] (1) First, two polymers, PCL (number average molecular weight 50,000) and PEO (number average molecular weight 100,000) are melt-blended, extruded, and granulated on a twin-screw extruder at a weight ratio of 50:50. It exists in the form of a continuous phase. Use a vacuum tablet press to press the PCL / PEO blend particles into a film (green body) with a thickness of 200 μm, and dry it in a vacuum drying oven for 24 hours to ensure that there is no residual moisture;

[0041] (2) Weigh 10g of PEO, put it into 90ml of deionized water, seal it and stir it at 25°C for 24 hours to obtain a completely dissolved PEO solution with a concentration of 10WT%, and use a mold to evenly coat it on PCL / PEO (50 / 50) the surface of the film material to obtain a protective green body with a thi...

Embodiment 3

[0048] Example 3 Preparation of polycaprolactone / polylactic acid (PCL / PLA) fully open-cell foaming material

[0049] (1) First, two polymers, PCL (number average molecular weight 50,000) and PLA (weight average molecular weight 130,000) are melt-blended, extruded, and granulated on a twin-screw extruder at a weight ratio of 70:30. The vacuum tablet press presses the PCL / PLA blended material into a film (green body) with a thickness of 300 μm, and dries it in a vacuum drying oven for 24 hours to ensure that there is no residual moisture;

[0050] (2) Weigh 10g of PEO, put it into 90ml of deionized water, seal it and stir it at 25°C for 24h to obtain a completely dissolved PEO solution with a concentration of 10WT%, and use a mold to evenly coat it on the PCL / PLA co- The surface of the mixture film was obtained to obtain a protective body with a PEO protective layer with a thickness of 10 μm on the surface; it was put into an oven, dried at 25°C for 2 days, and then taken out; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com