Device and method for degrading high temperature coke quenching waste water

A wastewater and high-temperature technology, applied in chemical instruments and methods, water/sewage treatment, natural water treatment, etc., can solve the problems of low equipment investment, unaffordable enterprises, high equipment investment, etc., to improve environmental quality, save treatment costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

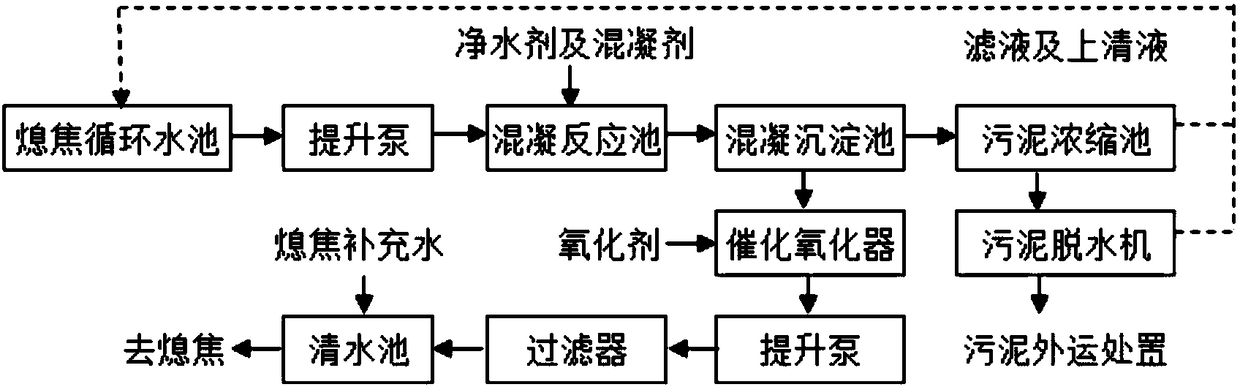

[0050] Below in conjunction with implementation case, the present invention is described in further detail, and its concrete process step is carried out in the following order:

[0051] A coke quenching circulating water volume of 300m in a coking plant 3 / h, COD is about 1000mg / L, and the water temperature fluctuates between 70-80°C. Design treatment water volume 60m 3 / h. The coke quenching wastewater first flows from the coke quenching tower to the coke quenching circulating pool. In the coke quenching circulating pool, most of the solid particles such as coke grains and coke powder are precipitated by natural precipitation. The upper layer of wastewater is pumped to the coagulation reaction tank through the lift pump.

[0052] The design residence time of coke quenching wastewater in the coagulation reaction tank is 30min, and the size of the coagulation reaction tank is 3.5×3.5×3m. The configured composite high-temperature water purifier is quantitatively dosed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com